A kind of automobile decorative cover bracket welding method

A welding method and decorative cover technology, which are applied in welding equipment, welding medium, welding equipment, etc., can solve the problems of poor rigidity at the weld, easy to break, and affect the normal use of the decorative cover, so as to ensure the use performance, tensile strength and The effect of improving the impact resistance index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

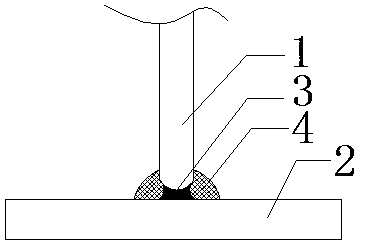

[0013] Such as figure 1 As shown, a method for welding a car decoration cover bracket, the process of welding the car decoration cover support 1 to the substrate 2 includes the following steps:

[0014] (1) Set the filling layer 3 between the car decoration cover bracket 1 and the substrate 2, the thickness of the filling layer 3 is 0.5-1.5mm, use H08A coated welding wire with a welding wire diameter of 1.17-1.21mm, and use carbon dioxide gas as the welding method Shielded welding, the welding specification parameters are: welding voltage 16-18V, welding current 135A, power supply polarity is DC reverse connection, wire feeding speed is 2.8m / min, gas flow rate is 18L / min, use ultrasonic wave after 24 hours of welding flaw detection;

[0015] Wherein, the coating is composed of the following raw materials in parts by weight: 35% of ferromanganese, 12% of ferronickel, 18% of lithium carbonate, 14% of potassium carbonate, 15% of silicon-calcium alloy, 4% of magnesium oxide, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com