Underwater wet welding device and method based on liquid protection

A wet welding and liquid technology, which is applied in the direction of protective supporting devices, welding equipment, welding accessories, etc., can solve the problems of surface slag loss, reduce weld formation, and weld surface unevenness, and achieve welding environment Effects of stabilization, reduction of longitudinal outflow, and output volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

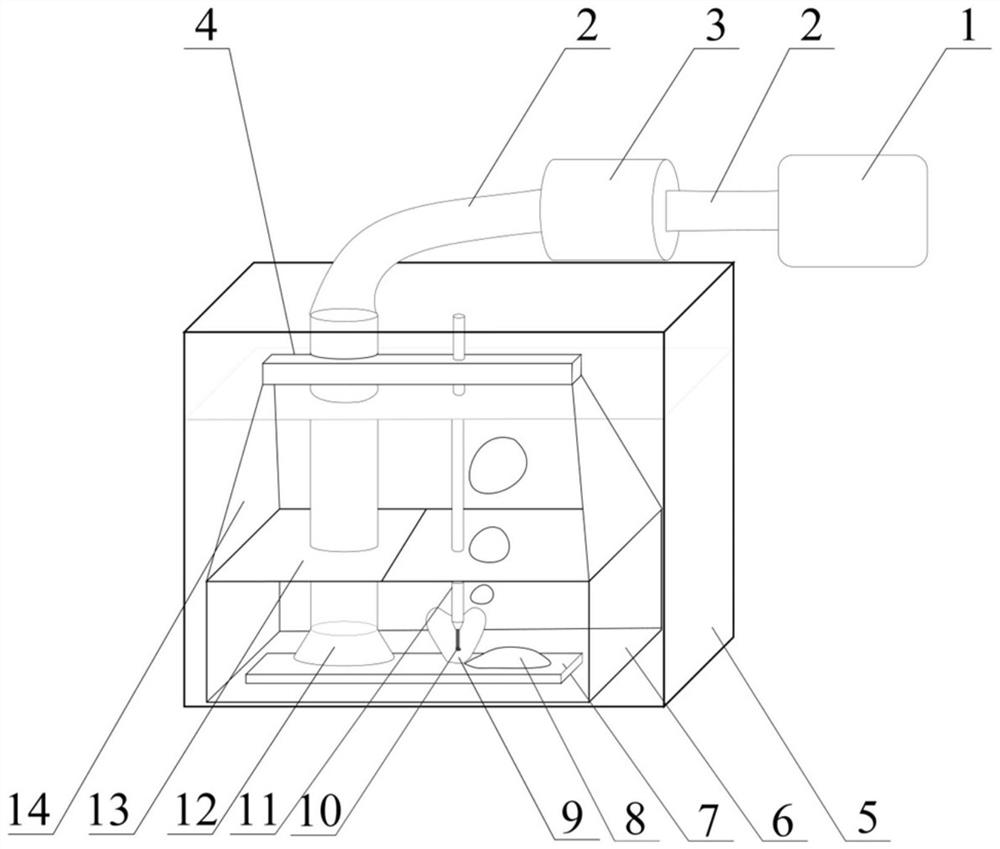

[0023] Such as figure 1 As shown, a kind of underwater wet welding device based on liquid protection provided by the present invention includes an automatic welding mechanism. The automatic welding mechanism includes an underwater welding torch 11. The underwater welding torch 11 is slidably connected to the welding torch mobile platform 4. The automatic welding mechanism A protective liquid input mechanism is provided in front of the movement of the protective liquid, and the protective liquid input mechanism includes a liquid storage tank 1, an infusion tube 2 and an infusion gun 12 connected in sequence. The liquid storage tank 1 is equipped with a protective liquid, which has higher density and viscosity than water, lower thermal conductivity than water, non-flammable, stable chemical properties, non-toxic to human body, no pollution to the environment, low price and easy to obtain. The protective liquid in the liquid storage tank 1 can be selected from one or more combina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com