A dual-axis rotary cutting and balanced high-pressure water jet cutting mechanism

A biaxial rotation and cutting mechanism technology, which is applied in the field of high-pressure water jet cutting mechanism, can solve the problems of difficulty in designing casting fixtures, inability to meet inclination angle cutting, and inability to circumscribe cutting, etc., achieve good motion reliability, and reduce the risk of personal safety. Likelihood, effect of reducing number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

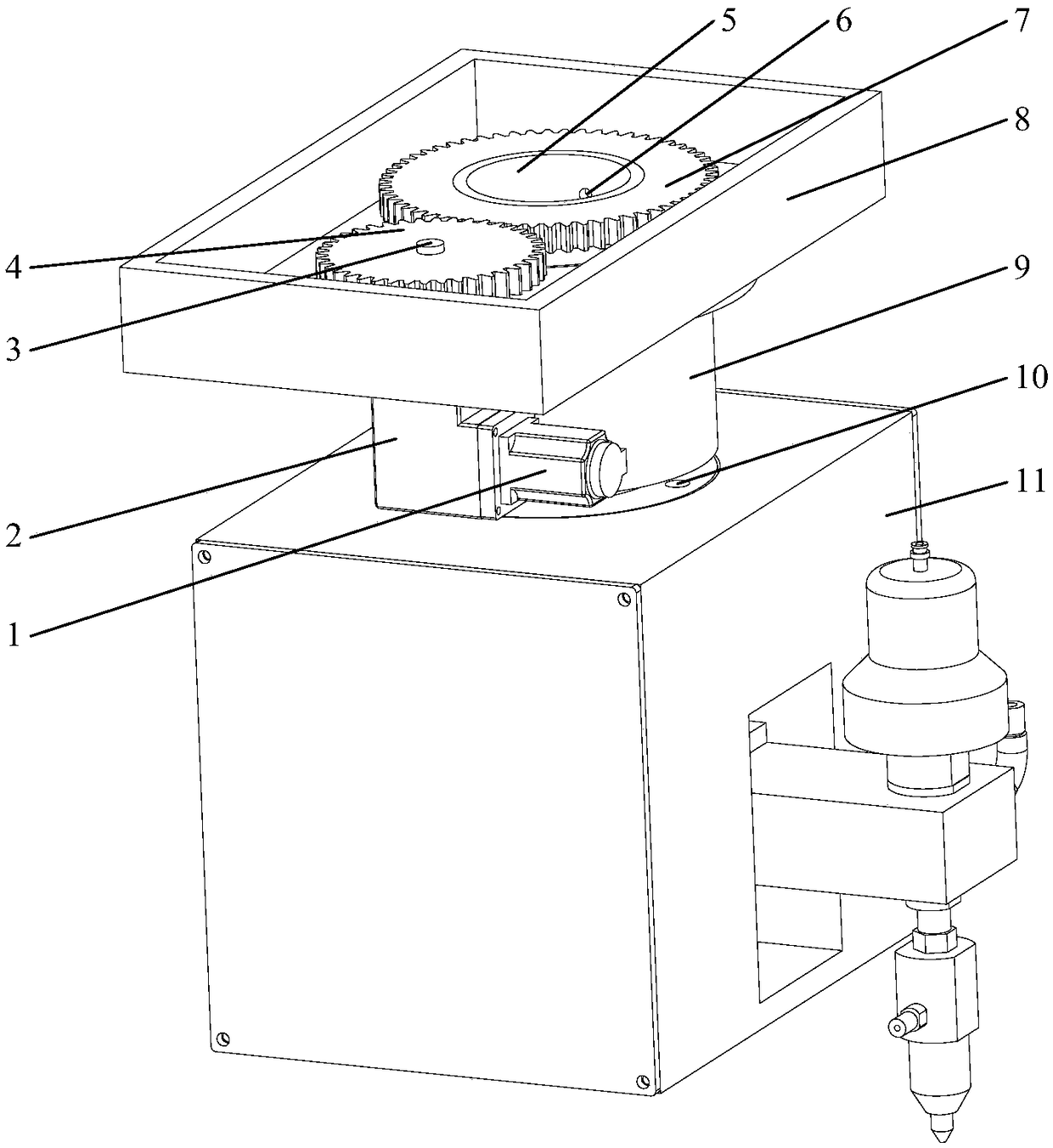

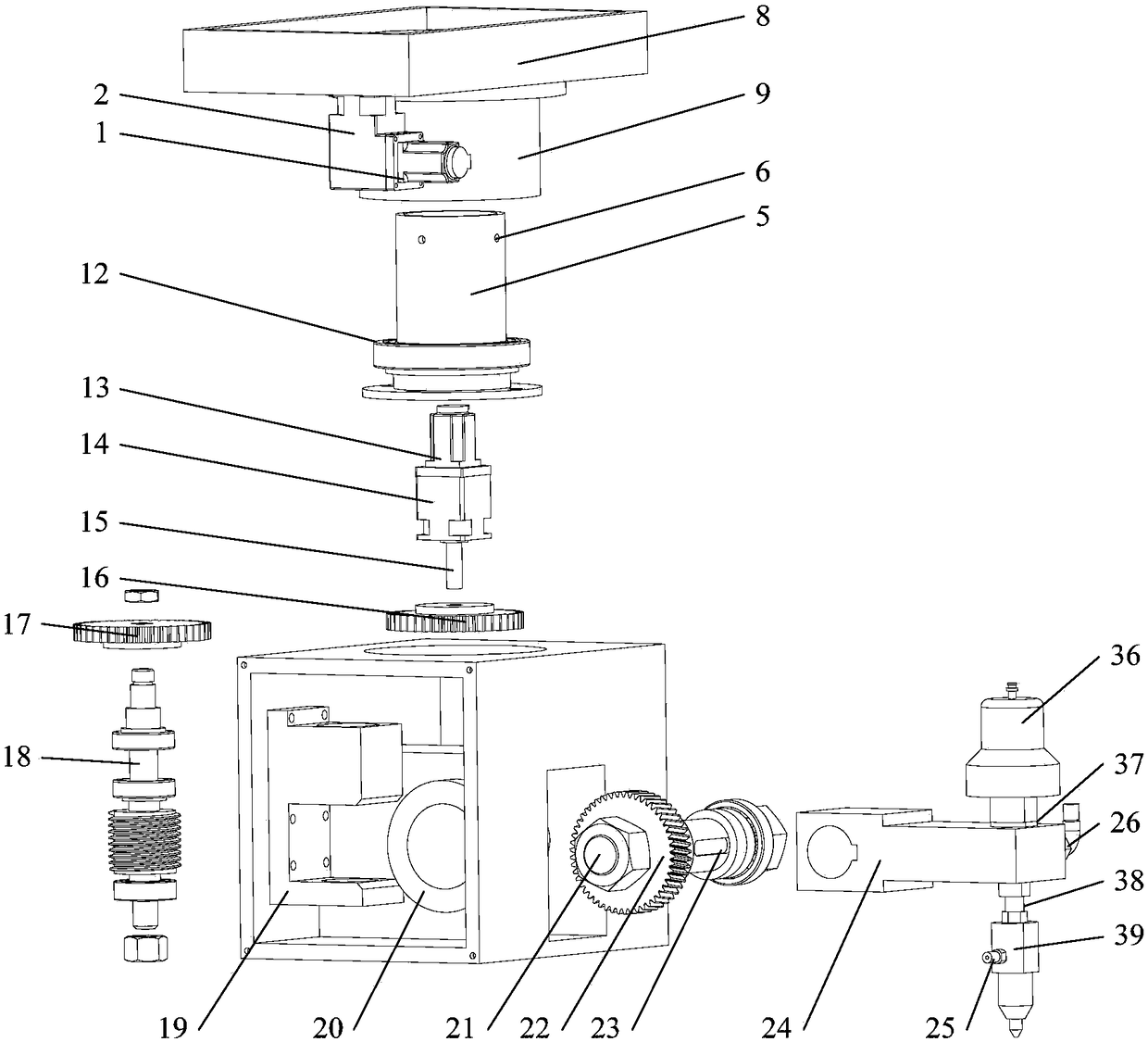

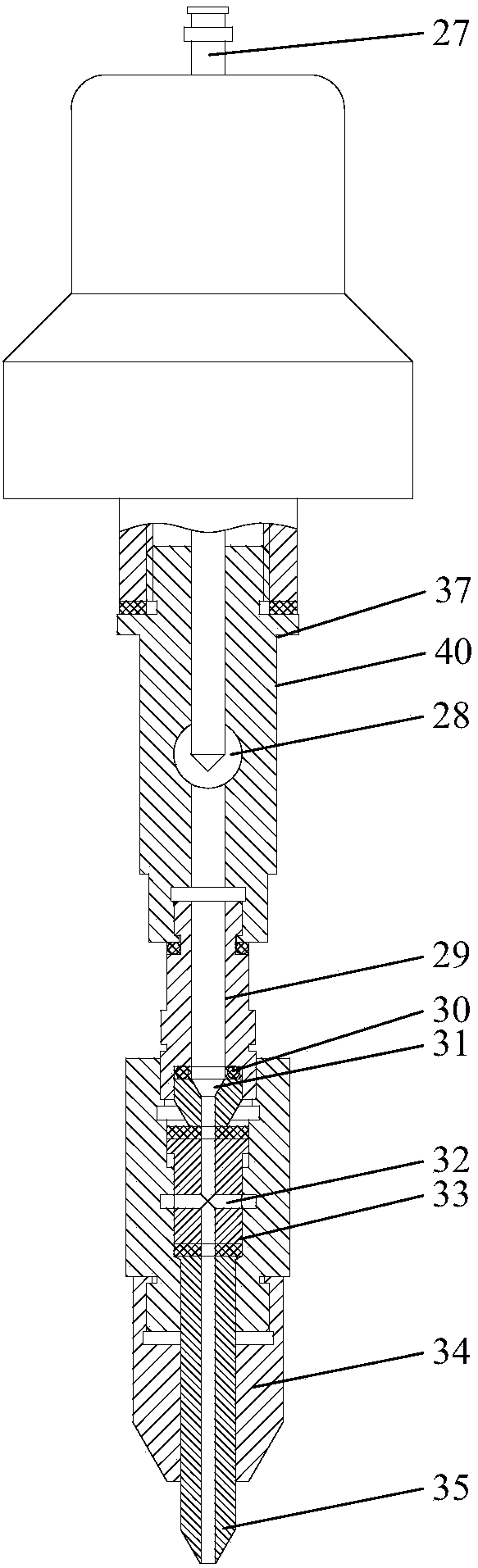

[0015] combine figure 1 , the rotary cutting platform consists of A-axis motor 1, A-axis reducer 2, A-axis output shaft 3, A-axis driving gear 4, base inner flange 5, pin shaft 6, A-axis driven gear 7, dustproof box Groove 8, base outer flange 9, slotted cylindrical screw 10, dustproof box casing 11 and tapered roller bearing 12 etc. are formed. The dust-proof box groove 8 plays a supporting and fixing role, and it can be installed on different machine tools for cutting. The A-axis motor 1 and the A-axis reducer 2 are fixed on the groove 8 of the dust-proof box through the hexagon socket head cap screws. The A-axis motor 1 is used as the power source, and the output power is transmitted to the A-axis output shaft 3 through the A-axis reducer 2. The A-axis output shaft 3 drives the A-axis driving gear 4 to rotate, the A-axis driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com