Method for preparing nanogold with size smaller than 5 nm through banana pulp extract

A banana pulp and extract technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as the lack of sodium hydroxide to control the reaction process, and achieve reduction of preparation costs and dispersion The effect of good performance and fast synthesis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

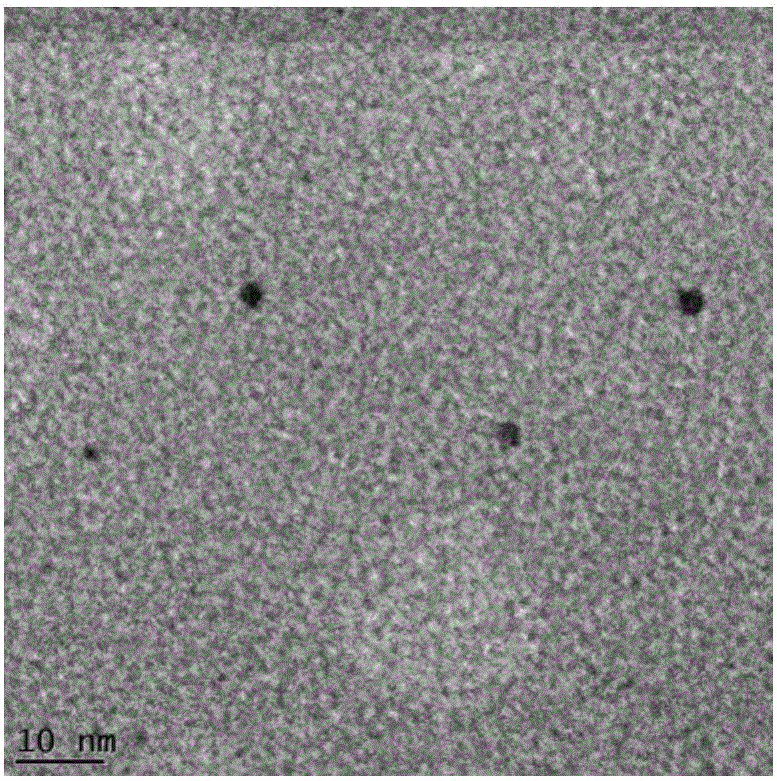

[0029] Add 0.75mL 2mmol / L gold chlorate aqueous solution to 1.91mL deionized water, then stir the solution and 0.2mL banana pulp extract in a boiling water bath and preheat to 96-100°C, extract the preheated banana pulp Add the preheated gold chlorate aqueous solution, continue to stir and heat in the boiling water bath for 5 seconds, then quickly add 0.14mL 0.2mol / L sodium hydroxide aqueous solution, and heat and stir in the boiling water bath for 5 minutes to obtain a particle size of 2.0±0.5nm spherical gold nanoparticle solution 3.00mL (see figure 1 ).

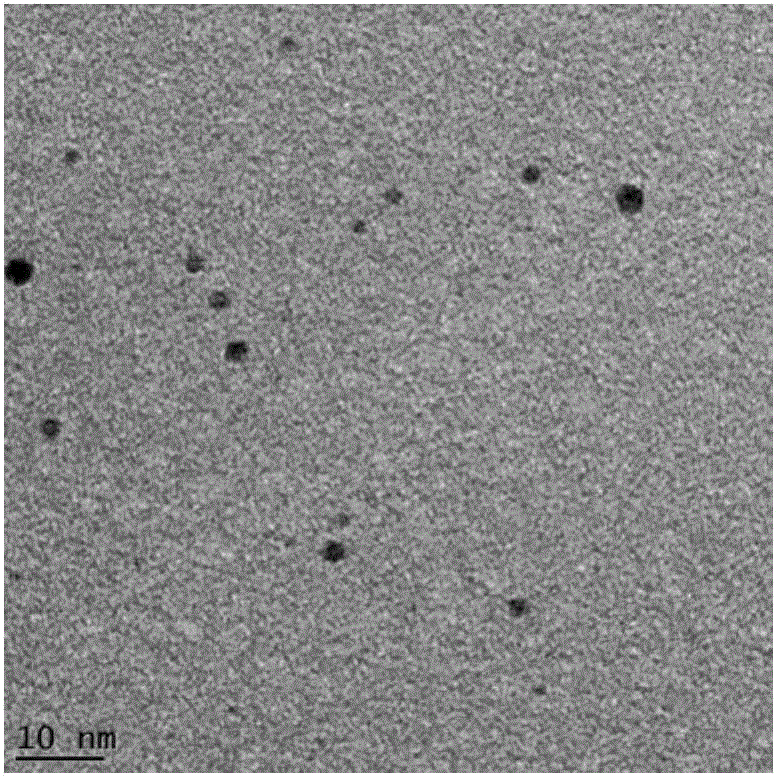

[0030] After the prepared nano-gold particle solution was left at room temperature for 3 months, the particle size and distribution of the nano-gold particles in the solution were characterized by a transmission electron microscope. The results are shown in figure 2 . It can be seen from the figure that the 2.0±0.5nm gold nano-particles prepared by the method of the present invention have good stability, and still maint...

Embodiment 2

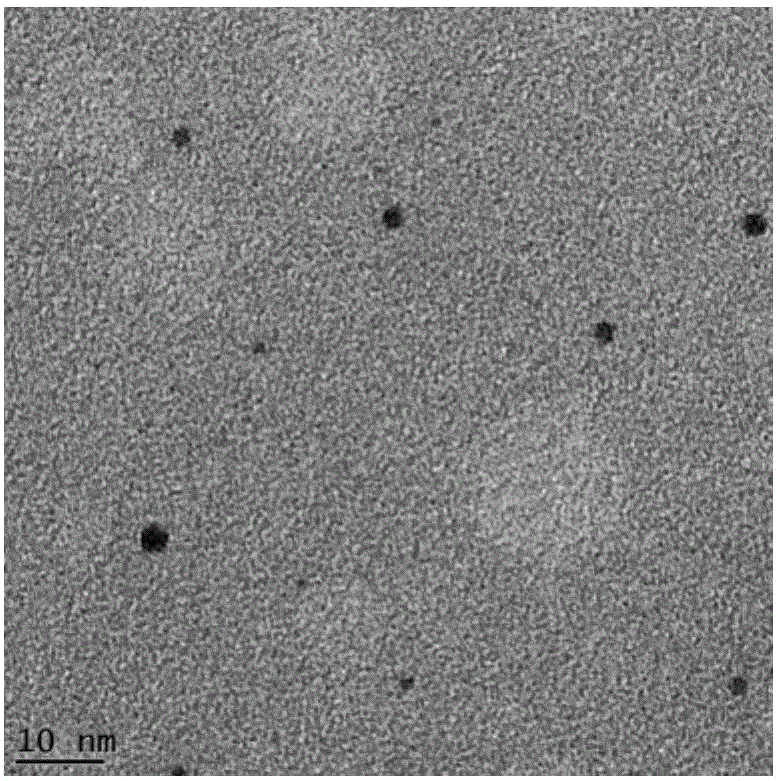

[0033]Add 0.75mL 2mmol / L gold chlorate aqueous solution to 2.03mL deionized water, then stir the solution and 0.2mL banana pulp extract respectively in a boiling water bath and preheat to 96-100°C, then put the preheated banana pulp Add the extract to the preheated gold chlorate aqueous solution, continue stirring and heating in the boiling water bath for 5 seconds, then quickly add 0.02mL 0.2mol / L sodium hydroxide aqueous solution, and heat and stir in the boiling water bath for 5 minutes to obtain the particle size 3.00mL of spherical gold nanoparticle solution of 3.1±1.3nm (see Figure 4 ).

[0034] After the prepared nano-gold particle solution was left at room temperature for 3 months, the particle size and distribution of the nano-gold particles in the solution were characterized by a transmission electron microscope. The results are shown in Figure 5 . It can be seen from the figure that the 3.1±1.3nm gold nano-particles prepared by the method of the present inventio...

Embodiment 3

[0037] Add 0.75mL 2mmol / L gold chlorate aqueous solution to 2.01mL deionized water, then stir the solution and 0.2mL banana pulp extract respectively in a boiling water bath and preheat to 96-100°C, then put the preheated banana pulp Add the extract to the preheated gold chlorate aqueous solution, continue stirring and heating in the boiling water bath for 5 seconds, then quickly add 0.04mL 0.2mol / L sodium hydroxide aqueous solution, and heat and stir in the boiling water bath for 5 minutes to obtain the particle size 3.00mL of spherical gold nanoparticle solution of 2.6±0.8nm (see Figure 7 ).

[0038] After the prepared nano-gold particle solution was left at room temperature for 3 months, the particle size and distribution of the nano-gold particles in the solution were characterized by a transmission electron microscope. The results are shown in Figure 8 . It can be seen from the figure that the 2.6±0.8nm gold nano-particles prepared by the method of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com