A kind of control method of coiling tower shape of silicon steel magnesia coating

A control method and magnesium oxide technology, which is applied in the field of metallurgy, can solve problems such as coiling towers that are prone to occur, and achieve the effects of preventing coiling towers, ensuring uniformity, and increasing output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

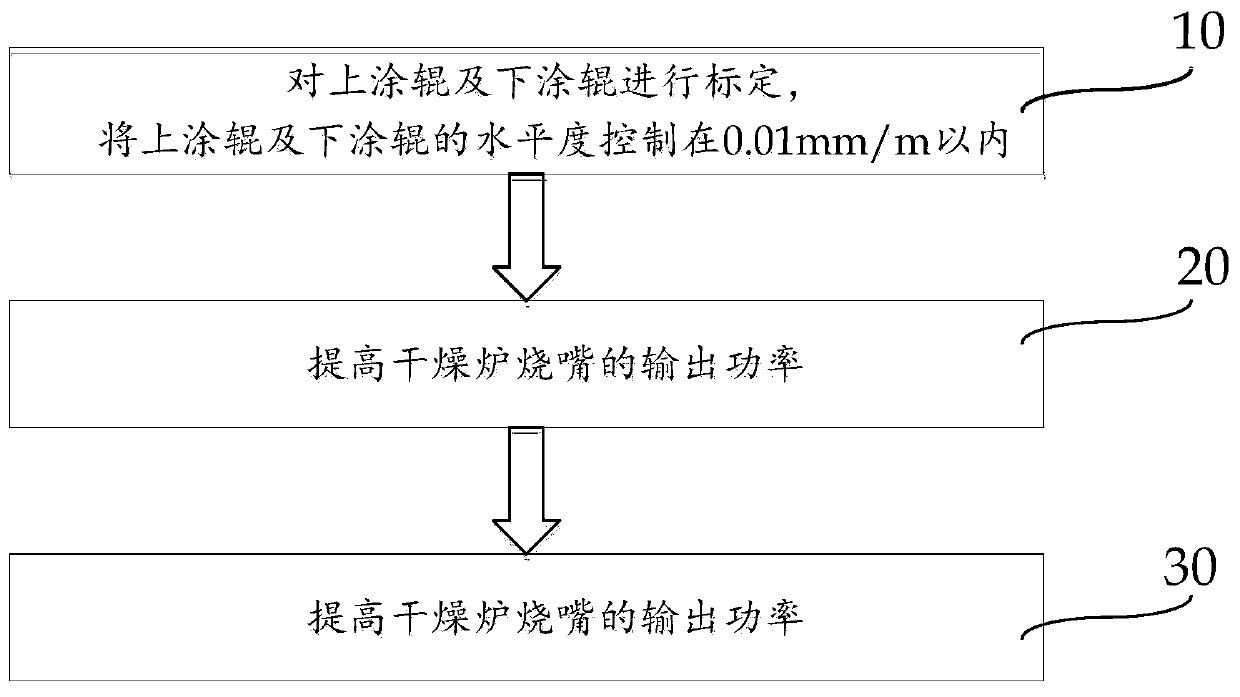

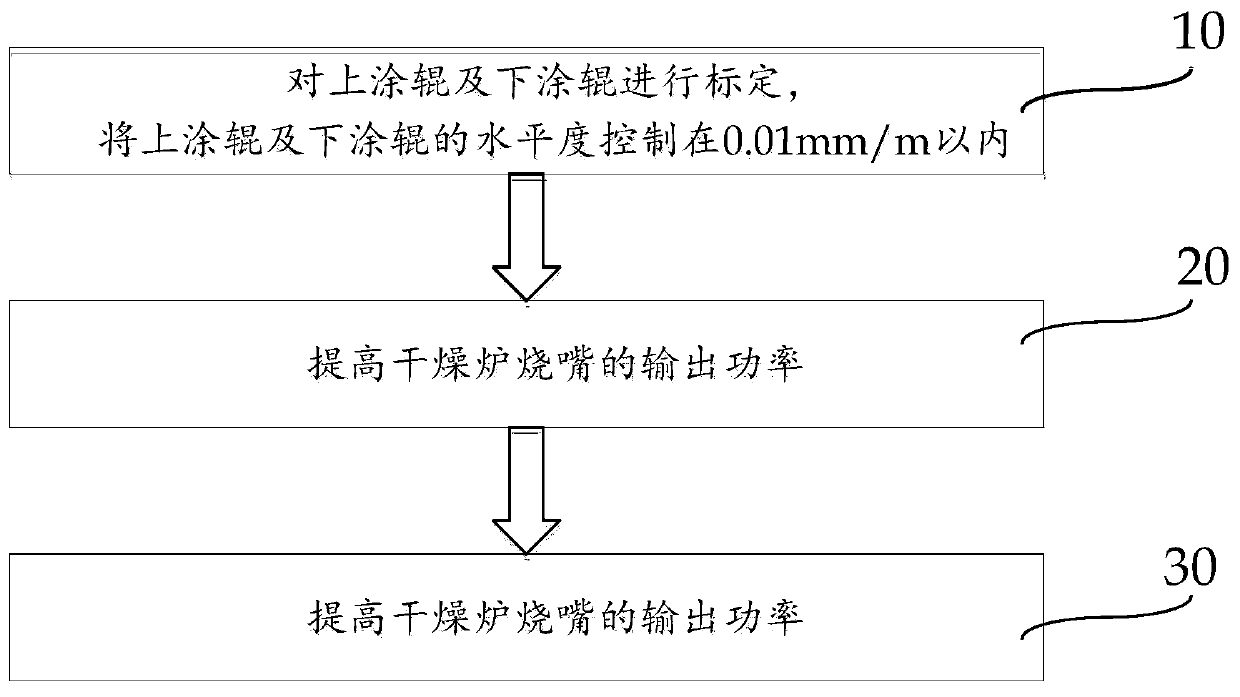

Method used

Image

Examples

Embodiment Construction

[0028] see figure 1 , in the production of silicon steel, because the coating roller (including the upper coating roller and the lower coating roller) of the coating machine is made of rubber material and is a driven roller, the friction force of the strip steel makes it rotate during use, which may easily cause the wear of the roller body , coupled with strip steel rolling plate problems (such as edge wave and transverse thickness difference), uneven lateral wear of the roll body, and changes in the level of the coating roll with the passage of time, will inevitably lead to the occurrence of uneven coating thickness. Coiled steel coil 1, the thickness deviation accumulates as the coiling diameter of steel coil 1 increases, and a conical coil appears, such as figure 1 shown. In the case of high-tension coiling, there is a transverse component force acting on the steel coil 1; at the same time, during the process of EPC adjusting the edge alignment of the strip steel, the late...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com