Medium-speed coal mill model building method based on system dynamics

A system dynamics and construction method technology, applied in the field of medium-speed coal mill modeling, can solve the problems of reducing the practicality and applicability of the model, and the quality of the model cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] Please refer to figure 1 , the present invention includes a coal mill output subsystem and a pulverized coal outlet temperature subsystem of the coal mill. The coal mill output subsystem is used to study the influence of coal supply and coal quality on the coal mill output. The coal pulverized coal outlet temperature subsystem of the coal mill is used to study the influence of coal supply, coal quality and primary air on the pulverized coal outlet temperature of the coal mill.

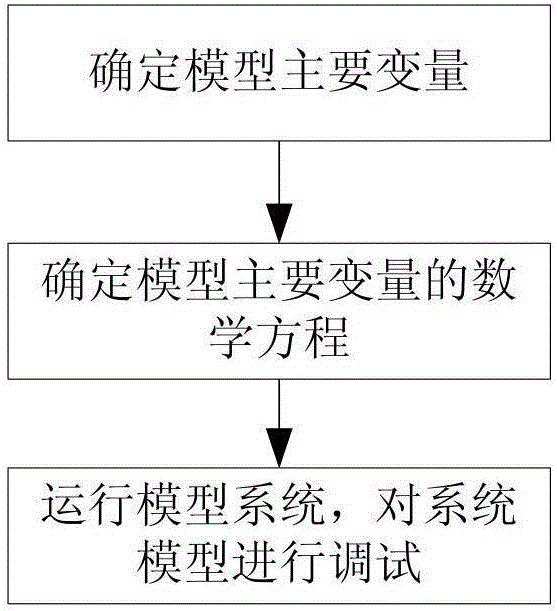

[0037] Please refer to figure 2 , the working process of the present invention is as follows:

[0038] 1. Determine the main variables of the model

[0039] The variables in the model are stock variables, flow variables and auxiliary variables. In order to simplify the model parameters, those parameters that do not change significantly with time are also approximately tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com