Nano-material for compounding CdZnS quantum dots and carbon dots, preparation method of nano-material and application

A technology of nanomaterials and quantum dots, which is applied in the field of nanomaterials and its preparation of CdZnS quantum dots and carbon dots, can solve the problems of high cost and immature production technology of single-layer graphene, and achieve stable cycle performance and benefit the industry. Chemical application and stable catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

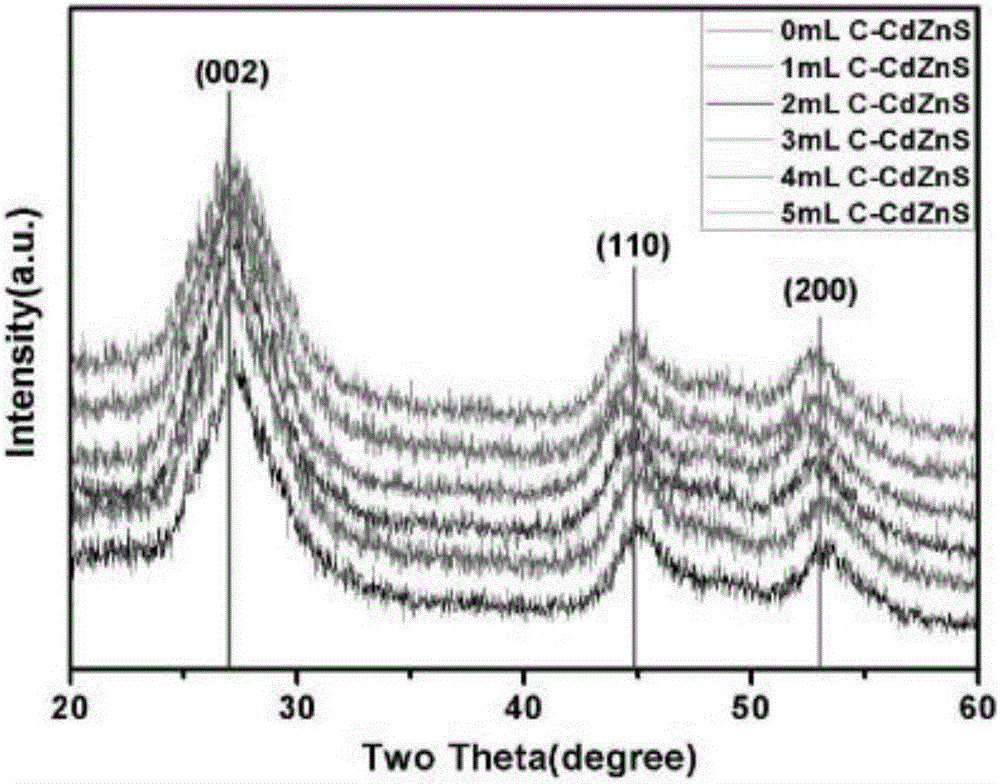

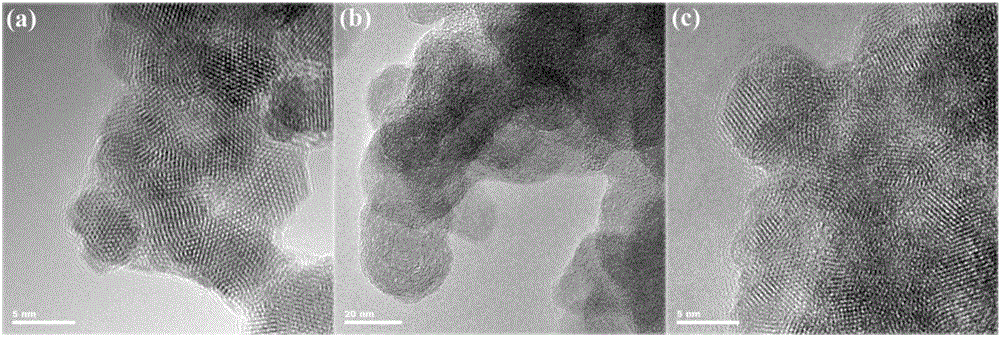

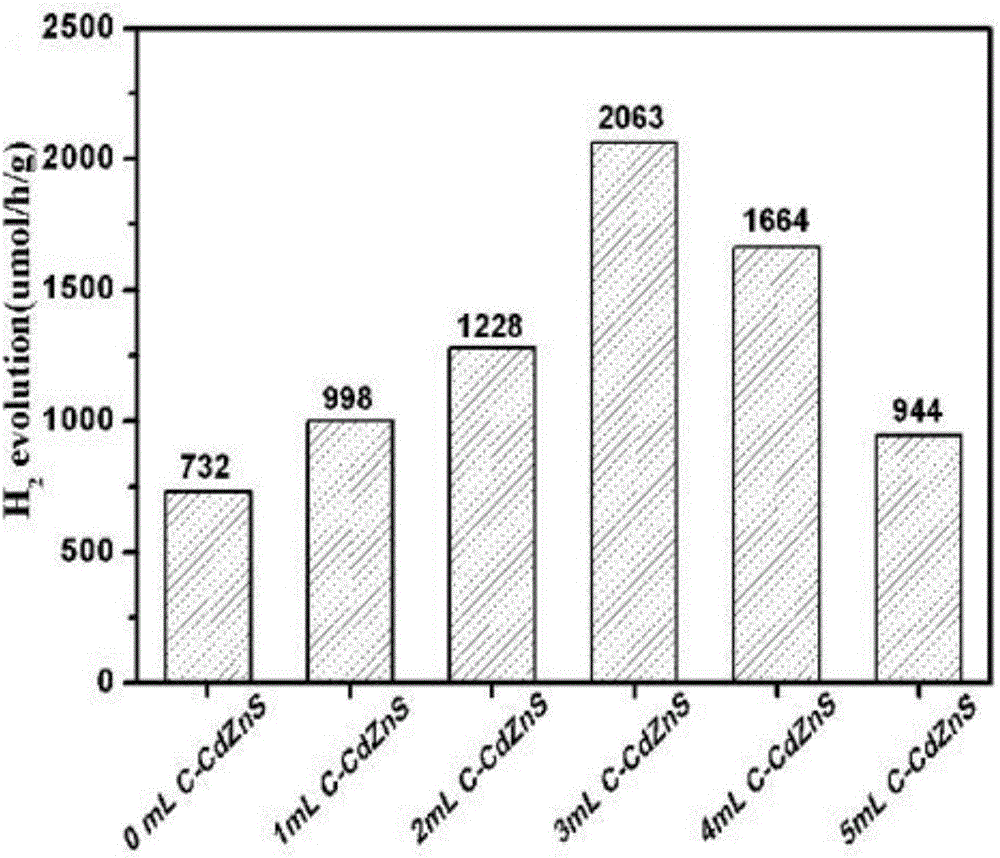

[0030] Example 1: Preparation of nanomaterials composed of CdZnS quantum dots and carbon dots.

[0031] 1) Add 1g of NaOH and 1g of polyvinyl alcohol into 40mL of deionized water, mix well by ultrasonic vibration, pour into a 50ml polytetrafluoroethylene liner, transfer to an autoclave, and keep warm at 220°C for 12 hours in an electric blast drying oven. After it reaches the reaction time, close the electric blast drying oven, let the whole reaction system cool down to room temperature naturally, then take out the inner container, and filter the product in the inner container with filter paper to obtain a golden yellow clear filtrate;

[0032] 2) Add 8% dilute hydrochloric acid drop by drop to the filtrate. After the filtrate becomes turbid, the solution is evenly divided into centrifuge tubes, centrifuged at a speed of 5000r / min, and the supernatant obtained by centrifugation is poured out, and then separately Add 5ml of ethylene glycol to the centrifuge tube to disperse the...

Embodiment 2

[0034] Example 2: Preparation of nanomaterials composed of CdZnS quantum dots and carbon dots.

[0035]1) Add 1g of NaOH and 1g of polyvinyl alcohol into 40mL of deionized water, mix them evenly by ultrasonic vibration, pour them into a 50ml polytetrafluoroethylene liner, transfer them to an autoclave, and keep them in an electric blast drying oven at 220°C for 12 hours. After it reaches the reaction time, close the electric blast drying oven, let the whole reaction system cool down to room temperature naturally, then take out the inner container, and filter the product in the inner container with filter paper to obtain a golden yellow clear filtrate;

[0036] 2) Add 8% dilute hydrochloric acid drop by drop to the filtrate. After the filtrate becomes turbid, the solution is evenly divided into centrifuge tubes, centrifuged at a speed of 5000r / min, and the supernatant obtained by centrifugation is poured out, and then separately Add 5ml of ethylene glycol to the centrifuge tube...

Embodiment 3

[0038] Example 3: Preparation of nanomaterials composed of CdZnS quantum dots and carbon dots.

[0039] 1) Add 1g of NaOH and 1g of polyvinyl alcohol into 40mL of deionized water, mix them evenly by ultrasonic vibration, pour them into a 50ml polytetrafluoroethylene liner, transfer them to an autoclave, and keep them in an electric blast drying oven at 220°C for 12 hours. After it reaches the reaction time, close the electric blast drying oven, let the whole reaction system cool down to room temperature naturally, then take out the inner container, and filter the product in the inner container with filter paper to obtain a golden yellow clear filtrate;

[0040] 2) Add 8% dilute hydrochloric acid drop by drop to the filtrate. After the filtrate becomes turbid, the solution is evenly divided into centrifuge tubes, centrifuged at a speed of 5000r / min, and the supernatant obtained by centrifugation is poured out, and then separately Add 5ml of ethylene glycol to the centrifuge tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com