A kind of vegetable oil-based zwitterionic surfactant and preparation method thereof

A technology of surfactant and zwitterion, which is applied in the field of vegetable oil-based amphoteric surfactant and its preparation, can solve the problems of high price and high price, achieve good compatibility and compatibility, easy compounding, and get rid of excessive dependence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

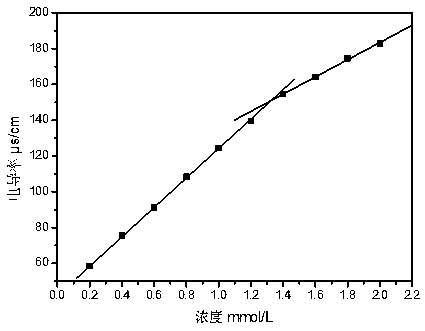

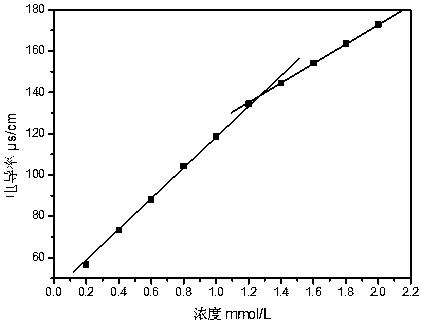

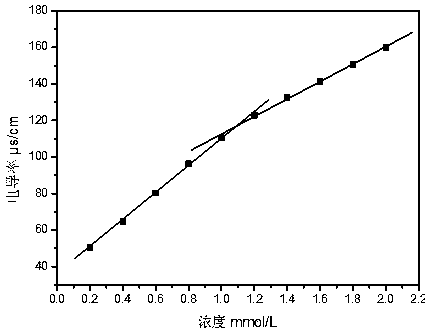

Image

Examples

Embodiment 1

[0028] (1) Add 100mL of 5 mol / L hydrochloric acid aqueous solution into a three-necked flask, stir and raise the temperature to 40°C, slowly add 0.5 mol of N,N-dimethylbutylamine to the aqueous hydrochloric acid solution dropwise, keep the reaction for 1h, then drop Add 1.5 mol ethanol solution containing 60% epoxidized soybean oil, control the temperature at 50°C, and react for 6 hours. After the reaction is completed, distill under reduced pressure to obtain a yellow transparent paste, which is further recrystallized and purified to obtain soybean oleyl butylamine salt.

[0029] (2) Take 10g of the soybean oleyl octylamine salt prepared in step (1) and fully dissolve it in 200mL of ethanol aqueous solution with a volume fraction of 95%, add 0.5g NaOH and stir for 4 hours under reflux, stop the reaction, filter, and wash the filter residue with absolute ethanol for 3 Second, vacuum drying to obtain soybean oil-based zwitterionic surfactant.

Embodiment 2

[0031] (1) Add 100mL of 5 mol / L hydrochloric acid aqueous solution into a three-necked flask, stir and heat up to 50°C, slowly add 0.5 mol of N,N-dimethyloctylamine to the aqueous hydrochloric acid solution dropwise, keep the reaction for 2 hours, then drop Add 1.5 mol ethanol solution containing 60% epoxy soybean oil, control the temperature at 60°C, and react for 8 hours. After the reaction is completed, distill under reduced pressure to obtain a yellow transparent paste, and further recrystallize and purify to obtain soybean oleyl octylamine salt.

[0032] (2) Take 10 g of the soybean oleyl octylamine salt prepared in step (1) and fully dissolve it in 200 mL of ethanol aqueous solution with a volume fraction of 95%, add 1 g of KOH to reflux and stir for 6 hours, stop the reaction, filter, and wash the filter residue 3 times with absolute ethanol , vacuum-dried to obtain soybean oil-based zwitterionic surfactant.

Embodiment 3

[0034] (1) Add 100mL of 5 mol / L hydrochloric acid aqueous solution into a three-necked flask, stir and heat up to 45°C, slowly add 0.5 mol of N,N-dimethyldodecylamine into the hydrochloric acid aqueous solution dropwise, and keep the reaction for 1.5h. Then 1.5 mol ethanol solution containing 60% epoxy soybean oil was added dropwise, the temperature was controlled at 55°C, and the reaction was carried out for 7 hours. After the reaction was completed, it was distilled under reduced pressure to obtain a yellow transparent paste, which was further recrystallized and purified to obtain soybean oil base dodecane amine salt.

[0035] (2) Take 10 g of the soybean oil base dodecylamine salt prepared in step (1) and fully dissolve it in 200 mL of ethanol aqueous solution with a volume fraction of 95%, add 0.8 g of KOH and stir under reflux for 6 hours, stop the reaction, filter, and wash the filter residue with absolute ethanol 3 times, vacuum drying to obtain soybean oil-based zwitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com