Continuous premixing method for acid ores

A technology of acid ore premixing, which is applied in mixing methods, chemical instruments and methods, mixers with rotating stirring devices, etc. It can solve the problems of inaccurate control of raw material input and continuous premixing, etc., to ensure stability , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

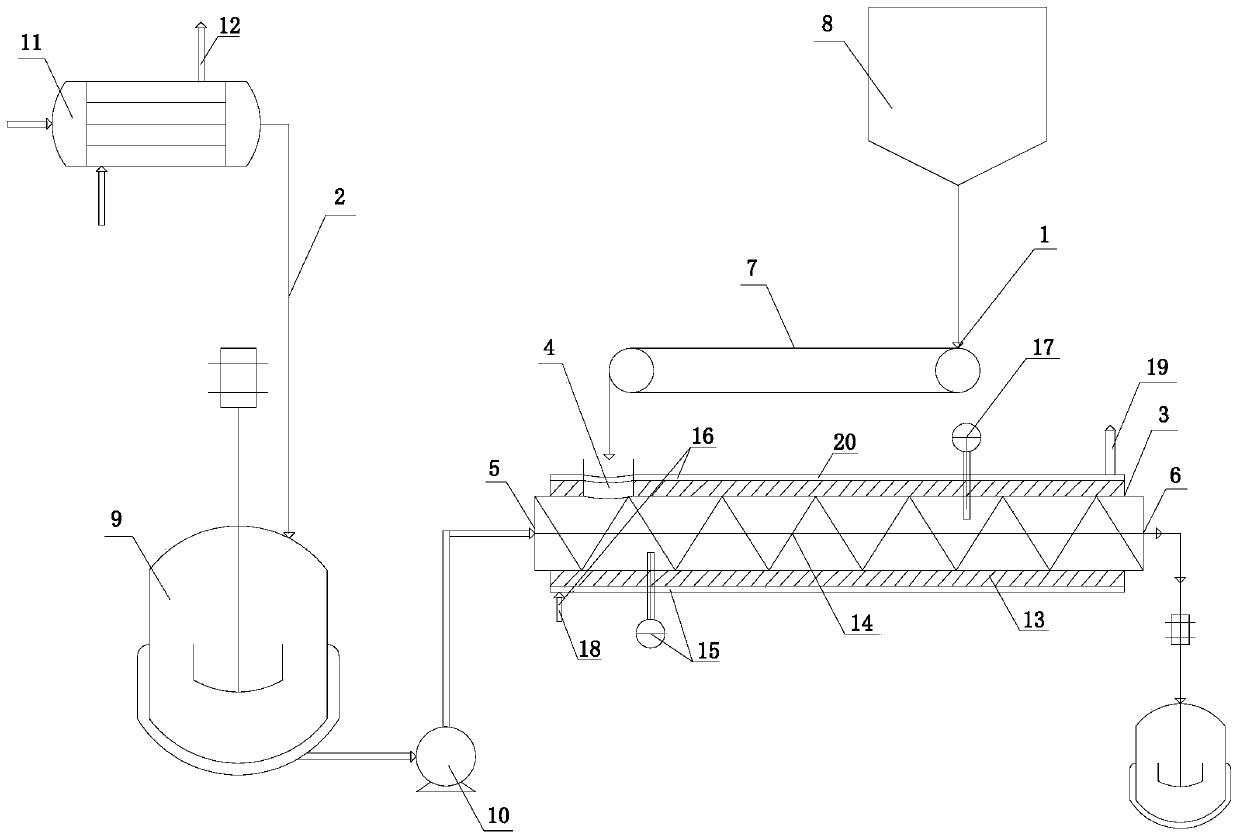

Method used

Image

Examples

Embodiment 1

[0024] Open the inlet and outlet valves of the frozen brine in the premix tank to ensure that the outlet temperature of the frozen brine is lower than 8°C. Turn on the stirring motor of the premix tank, and set the speed to 45 r / min. Turn on the concentrated sulfuric acid feed pump, and set the feed flow to 1.59m according to the process requirements 3 / h. Open the ilmenite conveying belt, then open the valve of the ilmenite silo, and adjust the feeding amount of the ilmenite to 0.85m according to the process requirements 3 / h. The premixed material enters the reaction feed tank and is pumped to the acid hydrolysis reactor, and the acid hydrolysis rate of the acid hydrolysis reaction is 98.24%.

Embodiment 2

[0026] Open the inlet and outlet valves of the frozen brine in the premix tank to ensure that the outlet temperature of the frozen brine is lower than 8°C. Turn on the stirring motor of the premix tank, and set the speed to 60 r / min. Turn on the concentrated sulfuric acid feed pump, and set the feed flow to 3.44m according to the process requirements 3 / h. Open the ilmenite conveying belt, then open the valve of the ilmenite silo, and adjust the feeding amount of the ilmenite to 1.7m according to the process requirements 3 / h. The premixed material enters the reaction feed tank and is pumped to the acid hydrolysis reactor, and the acid hydrolysis rate of the acid hydrolysis reaction is 98.75%.

Embodiment 3

[0028] Open the inlet and outlet valves of the frozen brine in the premix tank to ensure that the outlet temperature of the frozen brine is lower than 8°C. Turn on the stirring motor of the premix tank, and set the speed to 70 r / min. Turn on the concentrated sulfuric acid feed pump, and set the feed flow to 5.12m according to the process requirements 3 / h. Open the ilmenite conveying belt, then open the valve of the ilmenite silo, and adjust the feeding amount of the ilmenite to 2.55m according to the process requirements 3 / h. The premixed material enters the reaction feed tank and is pumped to the acid hydrolysis reactor, and the acid hydrolysis rate of the acid hydrolysis reaction is 99.10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com