Cup realizing color changing through temperature sensing

A temperature-sensing discoloration and temperature-sensing color-changing powder technology, which is applied to cooking utensils, beverage preparation devices, household appliances, etc., can solve the problems of destroying the external image of the cup body, the temperature-sensing discoloration is easy to fall off, and the manufacturing process is cumbersome, so as to reduce burns Possibility, no incidental consumption, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

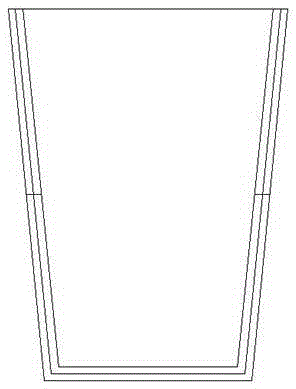

[0019] like figure 1 As shown, a temperature-sensitive color-changing cup body is a multi-layer cup body, the inner cup body is made of ordinary materials, and the outermost cup body is made of materials mixed with temperature-sensitive color-changing powder. A temperature transmission device is arranged between the inner cup body and the outermost cup body, so as to make the temperature on the two cup bodies consistent.

[0020] The temperature-sensitive color-changing powder is mixed with one or more types according to the temperature difference that needs to be displayed, and the critical color-changing temperature of various types of temperature-sensitive color-changing powders are not the same. The critical discoloration temperature of the first temperature-sensitive color-changing powder is 20°C-30°C. When the temperature is below 20°C, the first temperature-sensitive color-changing powder has no reaction. As the temperature increases, when the temperature reaches above ...

Embodiment 2

[0022] like figure 2 Shown is a temperature-sensitive color-changing cup body, the cup body is a single-layer cup body, and the cup body is made of a material mixed with a temperature-sensitive color-changing powder. That is to say, all the inner cups of the multi-layer cups in embodiment 1 are removed, only the outermost cup is left, and everything else is the same as in embodiment 1.

Embodiment 3

[0024] On the basis of Example 1, the outermost cup body is vertically divided into at least two layers of regions, and different types of temperature-sensitive color-changing powders are mixed into the materials of each layer of regions, and each layer of regions is mixed with the corresponding temperature-sensitive color-changing powder according to its material. The order of the critical discoloration temperature of the powder is arranged from bottom to top, and each layer of thermochromic material layer can be designed as a corresponding color and / or a corresponding digital pattern, etc.

[0025] The outermost cup body is divided into N layers of thermochromic areas from top to bottom. The critical discoloration temperature of the first thermochromic layer is 20°C-30°C. When the temperature is below 20°C, the first thermochromic layer has no reaction. As the temperature increases, when the temperature reaches above 20°C but not 30°C °C, the first thermochromic layer is in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com