A functional feed material for improving milk production and milk quality and its application

A feed, feed carrier technology, applied in application, animal feed, animal feed, etc., can solve the problems of inconvenient storage and transportation, restricting effective application, lack of soybean molasses comparison system and in-depth research, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the corn substitute of the present invention comprises mixing the soybean molasses product of the present invention with DDGS.

[0053] DDGS (Distiller's Grain Protein Feed) is dried distiller's grains containing soluble solids, mainly refers to the production of ethanol and carbon dioxide by mixed fermentation of corn seeds and selected yeast in a fuel ethanol factory with modern technology and equipment, and the remaining fermentation residue is dried at low temperature formed symbiotic products. The DDGS used in the present invention can be prepared by methods known in the art, and DDGS sold in the market can also be used directly.

[0054] When preparing the corn substitute material of the present invention, the mass ratio between soybean molasses product and DDGS is 30-70:70-30, for example, 30-50:70-50.

[0055] The corn substitute of the present invention can only be prepared by simply mixing the soybean molasses preparation of the pres...

Embodiment 1

[0086] Preparation of molasses bean curd and corn substitute:

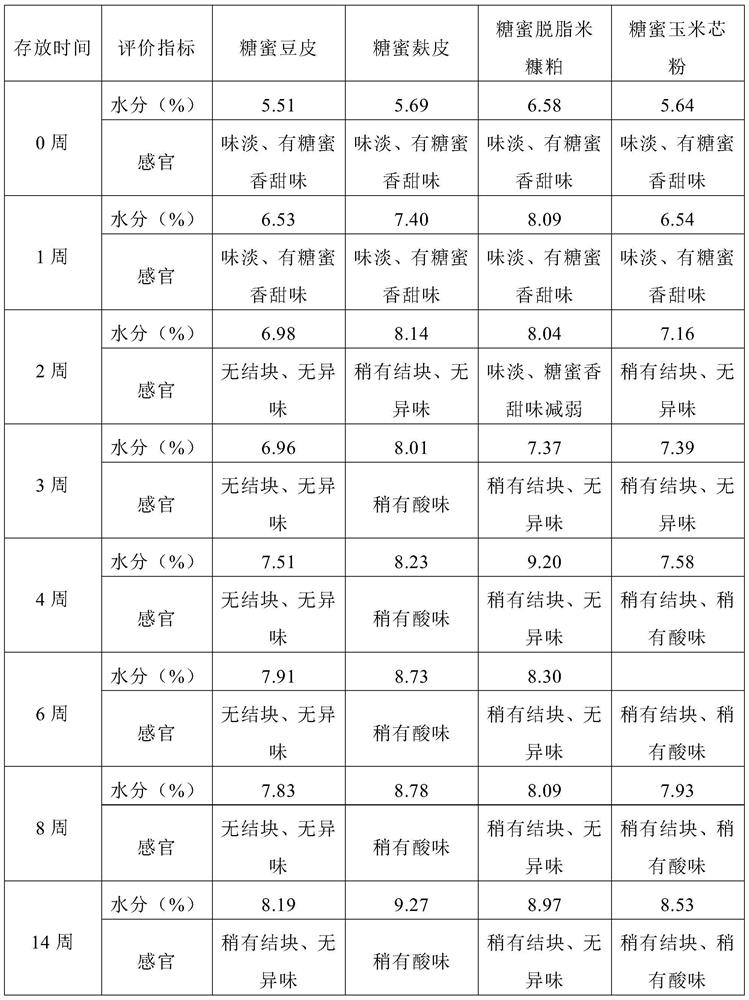

[0087] Get soybean skin 200kg, be placed in the blender, adopt molasses adding system to spray 100kg soybean concentrated molasses (moisture content 50%) in the blender, the addition speed is 40L / min, stir while adding, until blending, after blending After the molasses feed is conveyed by the auger, it is dried with hot air at a drying temperature of 80-105°C. After drying, the moisture content of the molasses bean curd is below 15%. After cooling, the molasses bean curd feed is obtained. Take the prepared molasses bean curd, mix it with DDGS, the mixing ratio is 42:58 (mass ratio), and use it as corn substitute material A for later use.

Embodiment 2

[0089] Preparation of Molasses Bran and Corn Substitute:

[0090] Get bran 200kg, be placed in the blender, adopt molasses adding system to spray 100kg soybean concentrated molasses (moisture content 50%) in the blender, the addition speed is 40L / min, stir while adding, until blending, after blending After the molasses feed is transported by the auger, it is dried with hot air at a drying temperature of 80-105°C. After drying, the moisture content of the molasses bran is below 15%. After cooling, the molasses bran feed is obtained. Take the prepared molasses bran, mix it with DDGS, the mixing ratio is 42:58 (mass ratio), and use it as corn substitute material B for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com