Reciprocating-impact heading machine with built-in rocker-arm telescopic cylinder

A technology of telescopic oil cylinders and roadheaders, which is applied to cutting machinery, driving devices, mechanical equipment, etc., can solve problems such as lubrication failure, high motor power, and damage to telescopic guide parts, etc., to achieve extended service life, high force transmission efficiency, Smooth stretching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

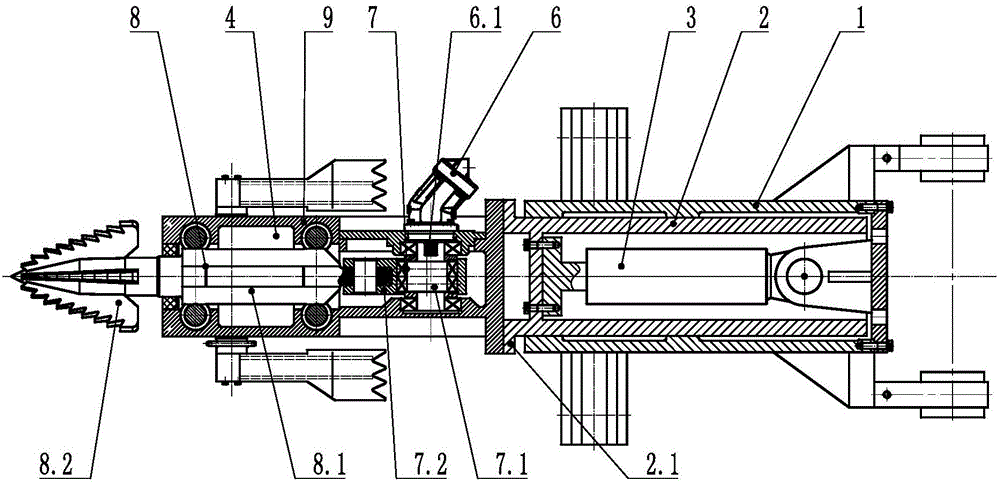

[0039] Such as Figure 1 to Figure 2 As shown, a reciprocating impact roadheader with a built-in rocker telescopic cylinder includes a telescopic outer cylinder 1, a telescopic inner cylinder 2, a telescopic cylinder 3, a reciprocating impact part 4, and a fuselage 5. The reciprocating impact part 4 includes an impact power source 6 , crank connecting rod assembly 7, impact guide assembly 8 and box body 9, etc., crank connecting rod assembly 7, impact guide assembly 8, etc. are arranged in the box body 9, crank connecting rod assembly 7 includes crankshaft 7.1 and connecting rod 7.2, etc., impact The guide assembly 8 includes an impact guide rod 8.1 and an impact head 8.2, etc. The impact guide rod 8.1 is arranged longitudinally, one end protrudes from the box body 9, and the other end is connected to the connecting rod 7.2, the crankshaft 7.1 is horizontally arranged on the box body 9, and the impact power source 6 includes The power shaft 6.1, etc., the power shaft 6.1 is pe...

Embodiment 2

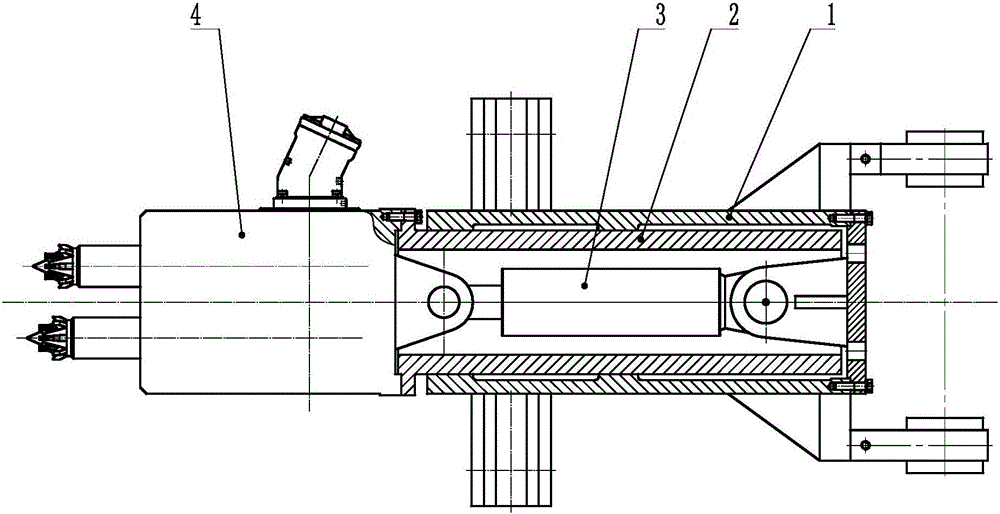

[0042] Such as image 3 As shown, a rocker telescopic oil cylinder built-in reciprocating impact roadheader, including a telescopic outer cylinder 1, a telescopic inner cylinder 2, a telescopic cylinder 3, a reciprocating impact part 4, etc., one end of the telescopic cylinder 3 is connected to the telescopic outer cylinder 1, and the telescopic cylinder 3 It is connected with the telescopic outer cylinder 1 through a pin shaft, the other end is connected with the reciprocating impact part 4, and the telescopic oil cylinder 3 is connected with the reciprocating impact part 4 through a pin shaft.

[0043] All the other are with embodiment 1.

Embodiment 3

[0045] Such as Figure 4 As shown, a reciprocating impact roadheader with a built-in rocker telescopic oil cylinder, the front end of the telescopic inner cylinder 2 is provided with a telescopic oil cylinder mounting

[0046] Mounting part 16, telescopic oil cylinder mounting part 16 and telescopic inner tube 2 are integrated, telescopic oil cylinder 3 and telescopic oil cylinder mounting part 16

[0047] Connected by bolts, the rear end of the telescopic outer cylinder 1 is provided with a telescopic oil cylinder rear support 17, and the telescopic oil cylinder rear support 17 is connected with the telescopic cylinder.

[0048] The outer cylinder 1 is connected separately, and the telescopic oil cylinder 3 is connected with the rear support member 17 of the telescopic oil cylinder through a pin shaft.

[0049] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com