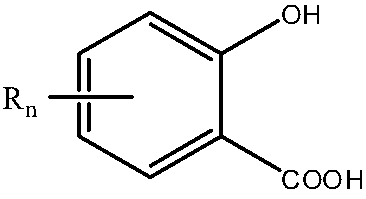

A kind of preparation method of chromium o-hydroxybenzoate containing substituent

A technology of o-hydroxybenzoic acid and substituent, applied in the field of organic compound preparation, can solve the problems of generating sticky agglomerates, low equipment efficiency and high production cost, achieve easy separation and washing, solve the problem of large equipment investment, and protect production equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

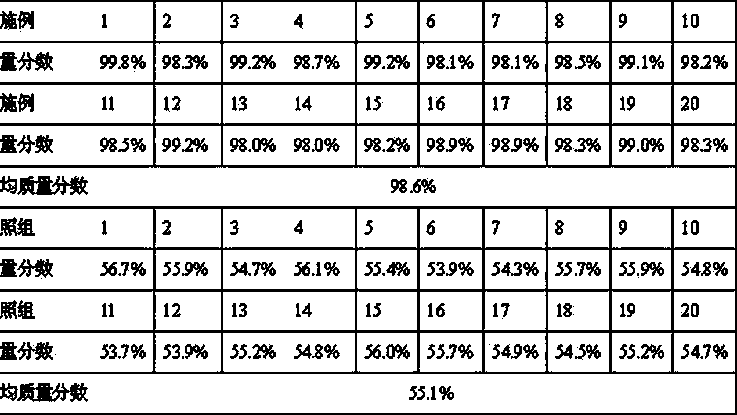

Examples

Embodiment 1

[0030] Measure 270ml of deionized water, weigh 5mol of chromium formate and 5mol of 3-nitro-o-hydroxybenzoic acid, pour deionized water into a 500ml reaction kettle, add chromium formate into water for dispersion treatment, and add all 3 -Nitro o-hydroxybenzoic acid and start to heat up slowly, control the temperature rise rate of the entire material mixing system to 0.2°C / min until the system boils, let the system react in the boiling state for 2 hours, then take a sample and filter, observe that the filtrate is colorless, chromium When the test paper detects that the chromium ion in the filtrate is lower than 0.5ppm, stop the reaction, filter, then wash and dry the product to obtain final product.

Embodiment 2

[0032] Measure 270ml of deionized water, weigh 5mol of chromium sulfate and 7mol of 5-methyl o-hydroxybenzoic acid, pour deionized water into a 500ml reaction kettle, add chromium sulfate into water for dispersion treatment, and add all 5 -Methyl o-hydroxybenzoic acid and start to heat up slowly, control the heating rate of the entire material mixing system to 0.25°C / min until the system boils, make the system react in a boiling state for 2.5h, then sample and filter, observe that the filtrate is colorless, When the chromium test paper detects that the chromium ion in the filtrate is lower than 0.5ppm, the reaction is stopped, filtered, and then the product is washed and dried to obtain final product.

Embodiment 3

[0034] Prepare 270ml of mixed solvent of water and ethanol, wherein the mass fraction of water is 80%, and the mass fraction of ethanol is 20%; weigh 3 mol of chromium acetate, 2 mol of chromium chloride and 10 mol of 3-ethyl-5-methoxy-o-hydroxybenzene Formic acid: Pour the mixed solvent into a 500ml reaction kettle, then add chromium acetate and chromium chloride to the mixed solvent for dispersion treatment, add all 3-ethyl-5-methoxy o-hydroxybenzoic acid while stirring and start Slowly heat up, control the temperature rise rate of the entire material mixing system to 0.3°C / min until the system boils, let the system react in a boiling state for 3 hours, then take a sample and filter, observe that the filtrate is colorless, and the chromium ion in the filtrate is lower than 0.5ppm by chromium test paper , stop the reaction, filter, then wash and dry the product to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com