Wheel type crane buffer type anti-back-tipping device

A crane and anti-backward tilting technology, which is applied to cranes and other directions, can solve the problems of shortening the service life of tire-mounted cranes and loss of crane structures, and achieve the effects of prolonging the service life, reducing injuries, and preventing backward tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

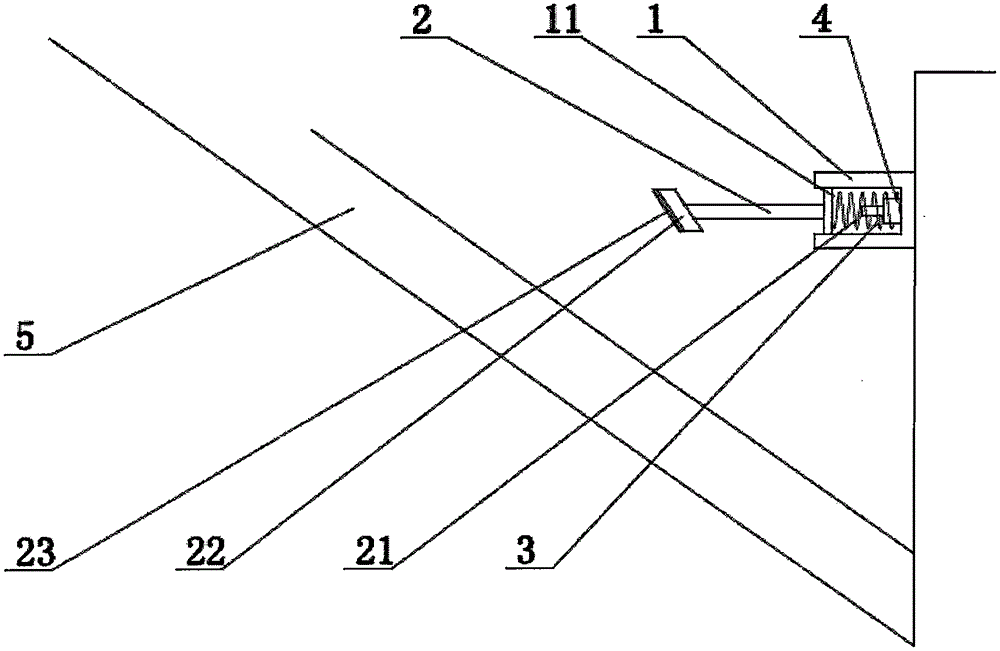

[0010] The buffer type anti-rolling device of the wheeled crane includes a mounting base 1, a ram 2, a spring 3 and a contact switch 4. The mounting base 1 is fixed on the crane and is located directly behind the jib 5 of the crane. A slot 11 is provided in the mounting seat 1, a contact switch 4 is arranged at the center of the bottom of the slot 11, the spring 3 is set on the outside of the contact switch 4, one end of the spring 3 is fixed on the bottom of the slot 11, and the other end is Fixed on the contact contact platform 21 provided at one end of the lance 2, the contact contact platform 21 is arranged in the slot 11, the other end of the lance 2 extends to the outside of the slot 11, and an impact platform 22 is provided, And the outer side of the impact platform 22 is pasted with a buffer rubber layer 23 , and the contact switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com