Correction device

A correction device and colonel technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of upper and lower mold deviation, rotation direction deviation, reduction of matching precision between mold base and turret hole, etc., and achieve reliable work and correcting The effect of the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

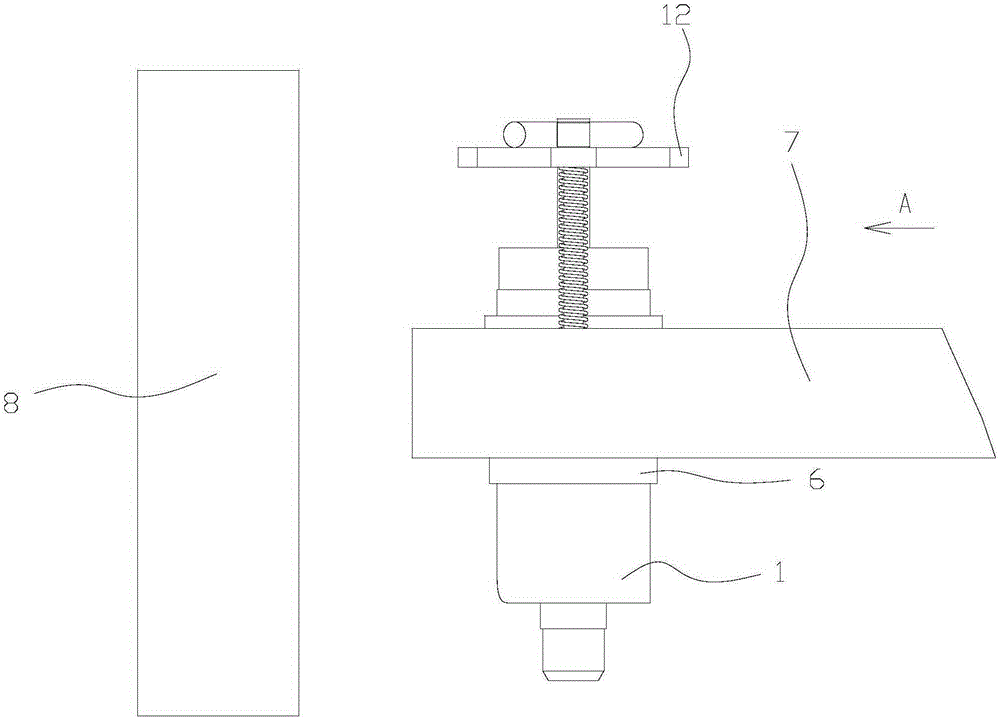

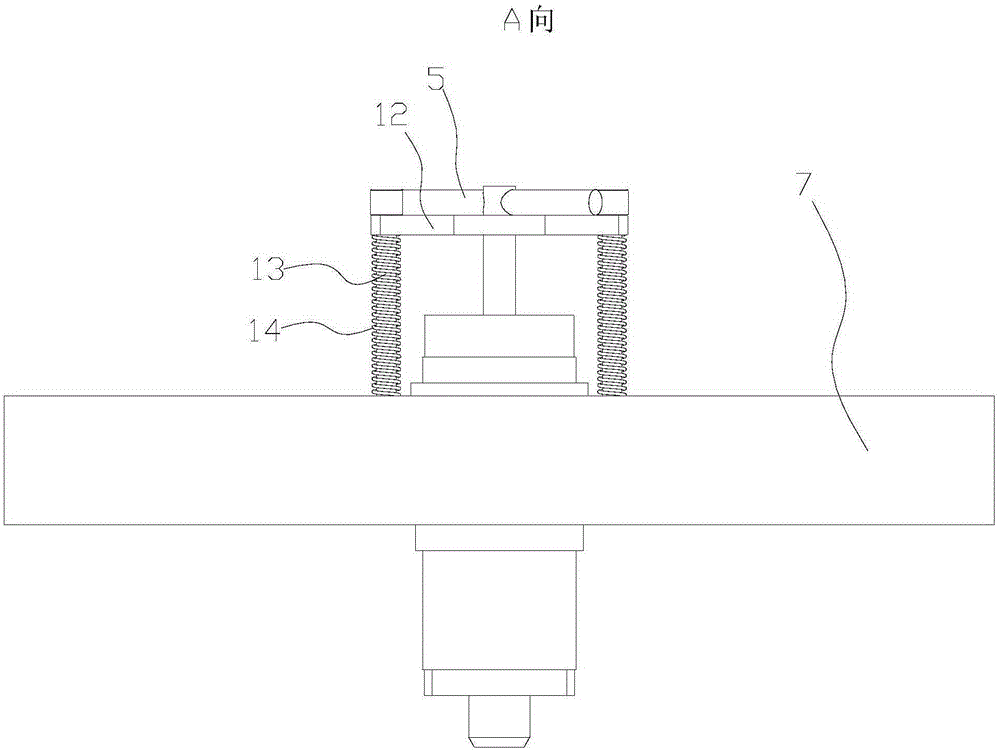

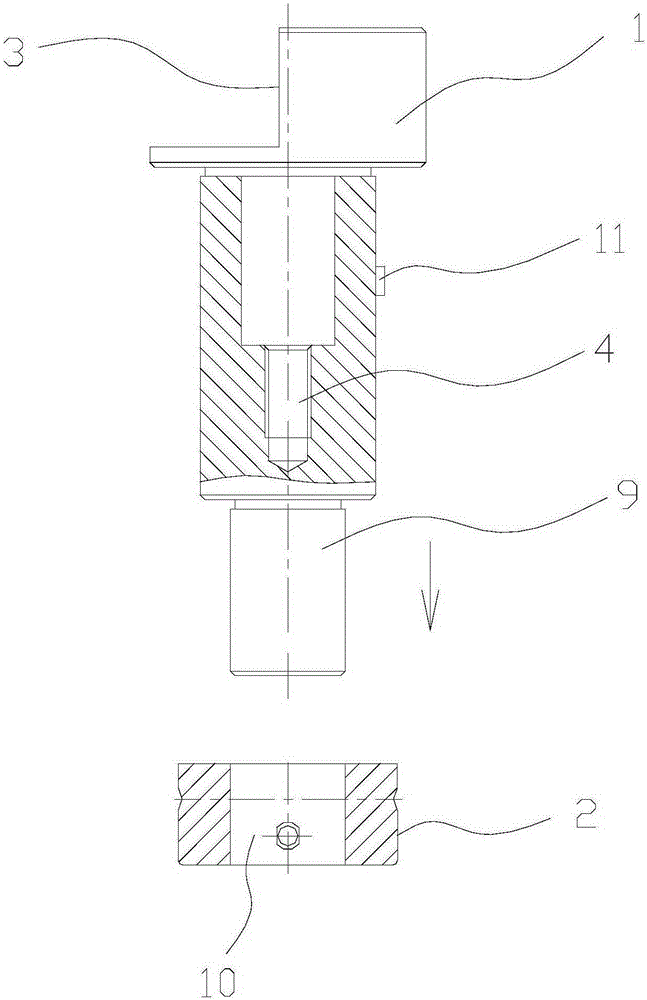

[0017] The invention as Figure 1-3 As shown, it includes an upper calibration rod 1, a lower calibration seat 2 and a dial indicator. The top side of the upper calibration rod 1 is provided with a straight section 3, and the center of the top surface of the upper calibration rod 1 is provided with a threaded hole 4. A threaded handle 5 is connected in the threaded hole 4;

[0018] The upper correction rod 1 is arranged in the middle hole of the upper mold cover 6, and the upper mold cover 6 is arranged on the turntable 7, and a guide rail 8 is provided on one side of the turntable;

[0019] The lower correction seat 2 is arranged in the lower mold base, the bottom of the upper correction rod 1 is provided with a cylindrical platform 9, and the top of the lower correction seat 2 is provided with a cylindrical hole 10 adapted to the cylinder;

[0020] The dial indicator is used for correcting the verticality of the upper die sleeve and the guide rail.

[0021] The upper calib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com