Method for producing an electronic module in particular for a motor vehicle transmission control unit

A technology of electronic modules and sensors, applied in the direction of mechanical equipment, transmission control, electrical equipment casing/cabinets/drawers, etc., can solve expensive and troublesome problems, and achieve the effect of reducing assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

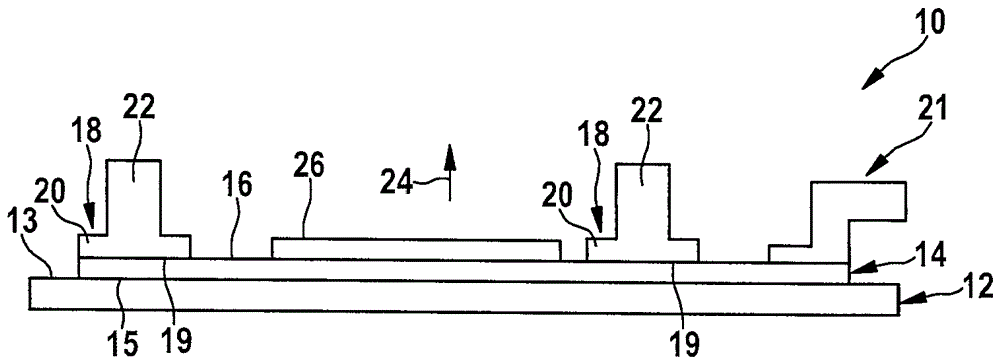

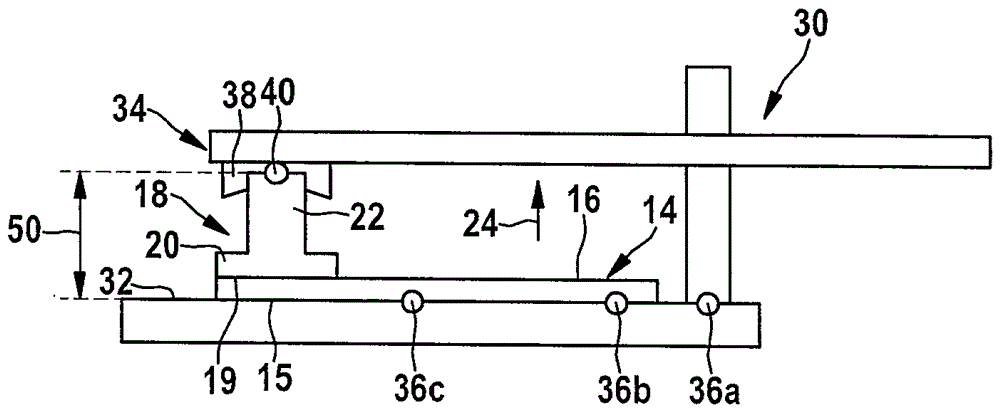

[0033] figure 1 An electronic module 10 produced according to the invention is shown, which is used, for example, as a transmission control module in a transmission control system.

[0034] The electronics module 10 has a carrier plate 12 which can be a metal plate or a metal-plastic composite plate. In particular, the carrier plate 12 can be used as a heat sink for the electronics module 10 and is provided for heat dissipation.

[0035] On the side 13 of the carrier plate 12 a printed circuit board element 14 is arranged completely planarly. For example, the printed circuit board element 14 can be glued, soldered and / or welded to the side 13 of the carrier plate 12 with the outer side 15 .

[0036] As described above and in more detail below, two sensor elements 18 are arranged and fixed according to the invention on the outer surface 16 of the printed circuit board element 14 which is situated opposite the outer side 15 . The sensor element 18 can be a so-called sensor do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com