Inkjet printing system and method of processing wafers

An inkjet printing, wafer technology, applied in printing, printed circuit, printed circuit, etc., can solve the problem of expensive sliders for sports cameras

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The drawings illustrate examples of inkjet printing systems in which various embodiments of the invention are incorporated. It should be noted that the embodiments can also be applied independently and that the invention is not limited to the examples shown in the drawings. Various embodiments will be described below, wherein reference numerals will be used to refer to the accompanying drawings. Reference numerals are used herein for the purpose of description and do not have a limiting effect. Embodiments can also be implemented differently than the examples shown in the drawings.

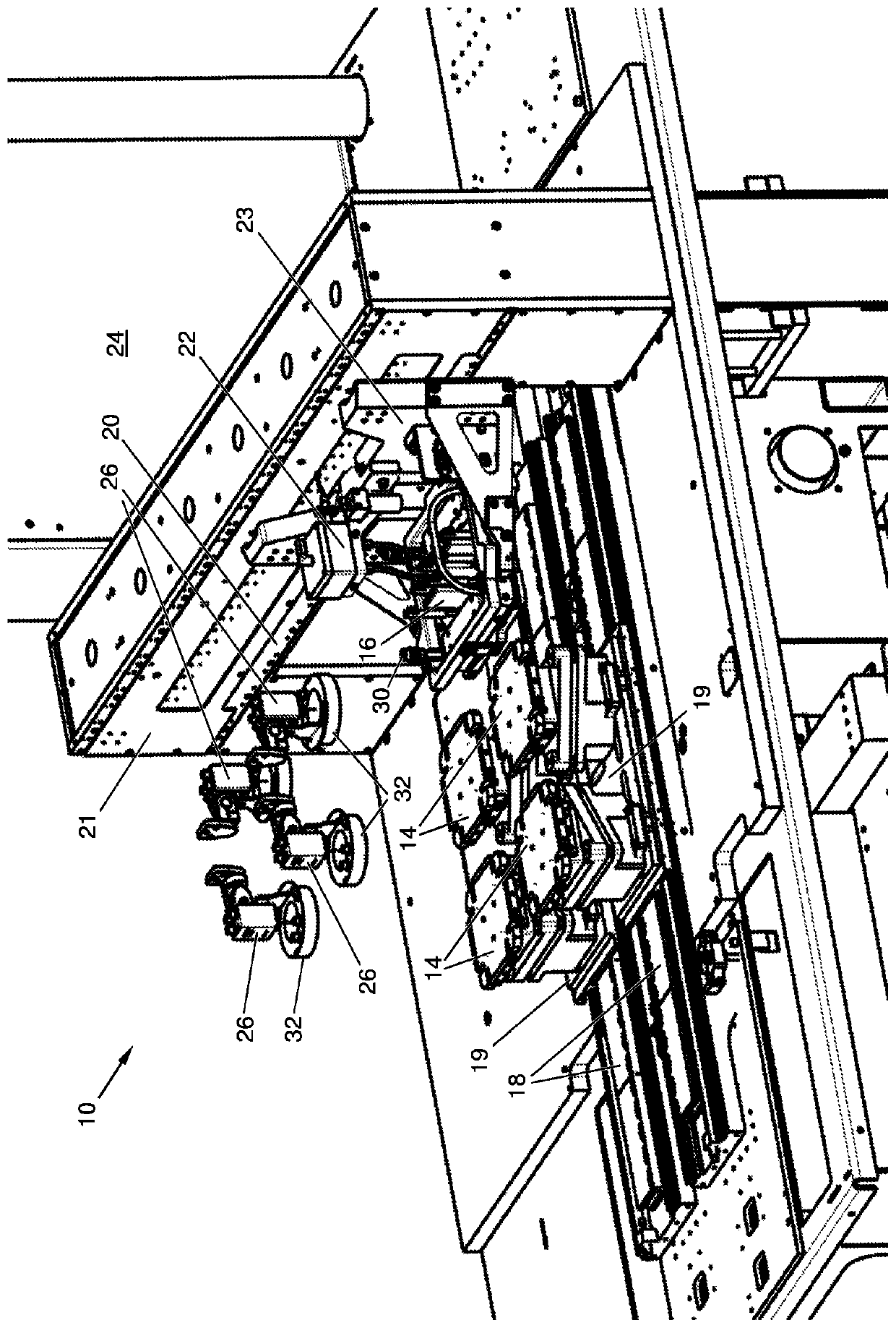

[0039] In general, the present disclosure relates to an inkjet printing system 10 configured to print a pattern of liquid material onto a wafer W supplied at a high volume. An example of such an inkjet printing system 10 is in figure 1 shown in .

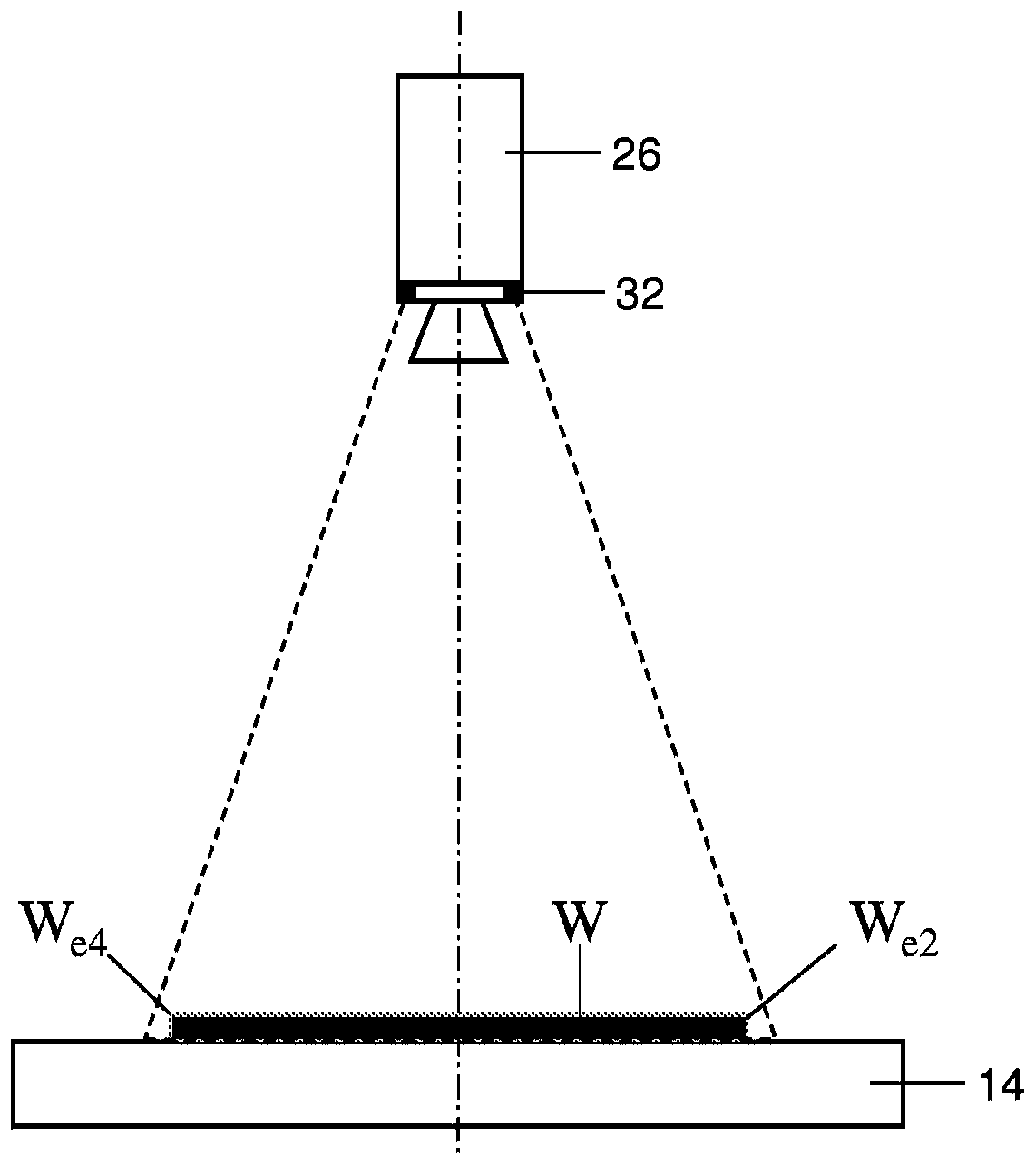

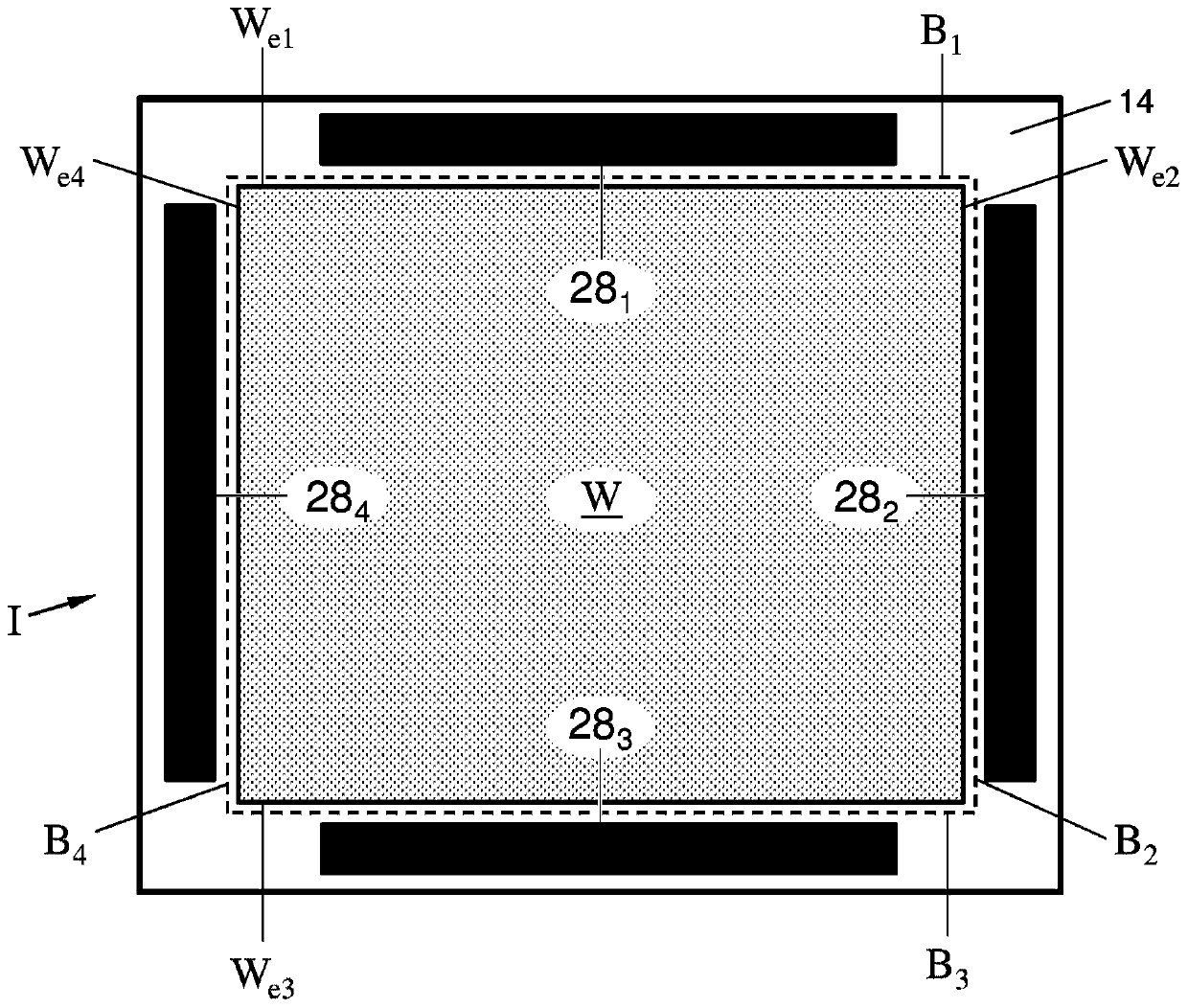

[0040] Each wafer W has wafer edges W extending in at least two different directions e . The system includes at least one chuck 14 on whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com