Conductor shunt

A technology of shunts and wires, which is applied in vehicle connectors, electrical components, bases/housings, etc., can solve problems such as lower production pass rate, poor sealing performance, and wire breakage, so as to improve the probability of circuit breakage, good overall performance, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

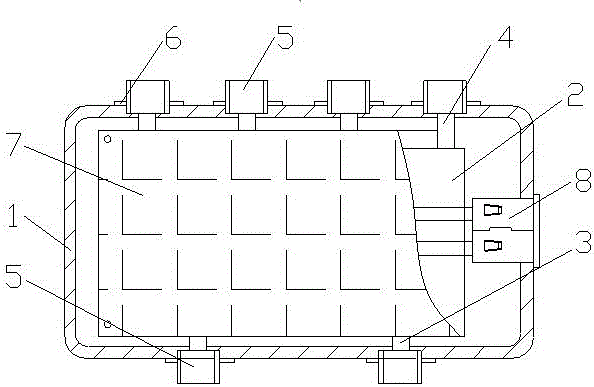

[0010] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a wire shunt proposed by the present invention.

[0011] refer to figure 1 , a wire shunt proposed by the present invention includes: a sealed casing 1 and a guide 5, and a PCB circuit board 2, an incoming conductive tube 3 electrically connected to the main wiring harness, and a shunt The outgoing conductive tube 4 electrically connected to the wiring harness; the PCB circuit board 2 is provided with a circuit for realizing the shunting of the electrical signal of the main wiring harness and the shunt wiring harness; the incoming conductive tube 3 and the outgoing conductive tube 4 are all connected to the PCB The circuit board 2 is connected and energized, and the incoming conductive pipe 3 and the outgoing conductive pipe 4 are provided with jacks; the sealed housing 1 is provided with a mounting hole communicated with the socket, and the mounting hole There is an internal thread inside; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com