Method for assembled integral type reinforced concrete slab bridge

A reinforced concrete slab and monolithic technology, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problem of affecting the durability and performance of bridges, the inability to realize parallel construction of upper and lower structures, and affecting the bearing capacity and safe operation of bridges and other problems to achieve the effect of saving maintenance and repair and reinforcement costs, avoiding the occurrence of single-board stress, and saving templates and brackets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

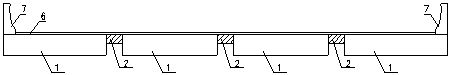

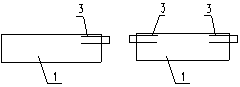

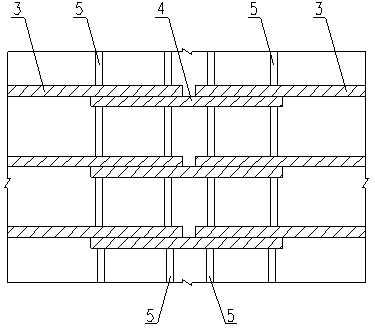

[0025] (1) Install the prefabricated reinforced concrete slab 1, and form the construction groove of the wet joint 2 between two adjacent prefabricated reinforced concrete slabs 1, the height of the wet joint 2 is 15 cm, and the top of the wet joint 2 is connected with the prefabricated reinforced concrete The top of the slab 1 is flush, and the side of the prefabricated reinforced concrete slab 1 is in contact with the wet joint 2. The opening ends of the U-shaped connecting steel bars 3 are embedded inside, and the U-shaped connecting steel bars 3 protrude from the closure of the prefabricated reinforced concrete slab 1. The end extends into the wet joint 2, and the rectangular stirrup 4 is arranged at the closed end of the U-shaped connecting steel bar 3 embedded in the two adjacent prefabricated reinforced concrete slabs 1, and the U-shaped connecting steel bar 3 and the rectangular stirrup 4 The longitudinal structural reinforcement 5 is arranged in the overlapping area, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com