Lithium battery convenient for battery core coiled material to exhaust

A lithium battery and lithium battery separator technology, applied in lithium batteries, non-aqueous electrolyte batteries, electrical components, etc., can solve problems such as unfavorable gas discharge, achieve extended stability, good corrosion resistance and high temperature resistance, and stable use characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

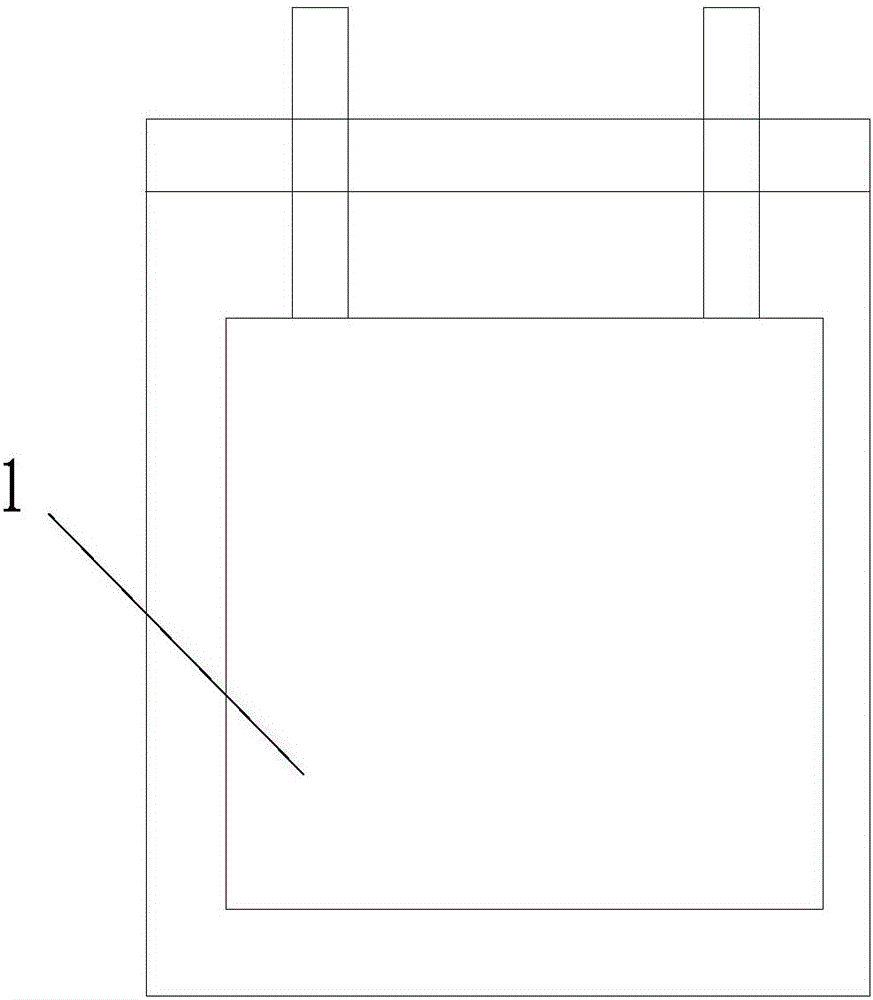

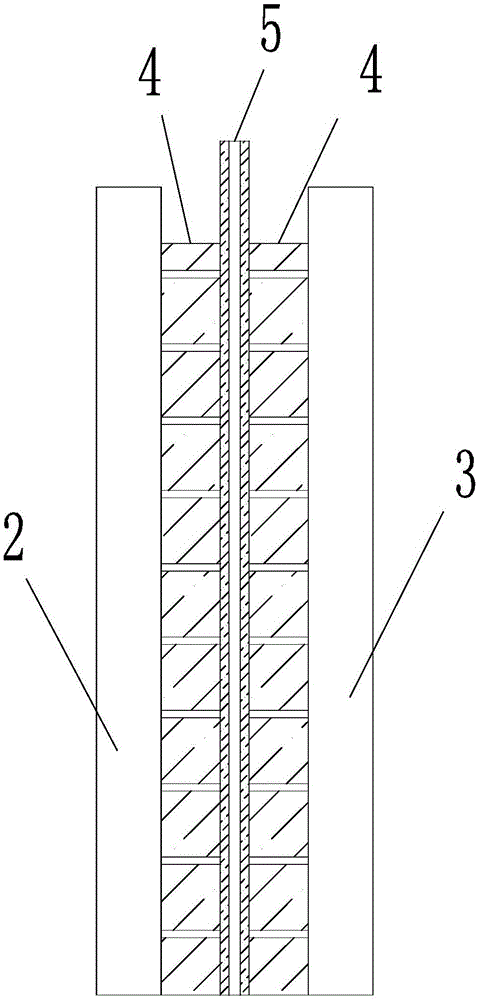

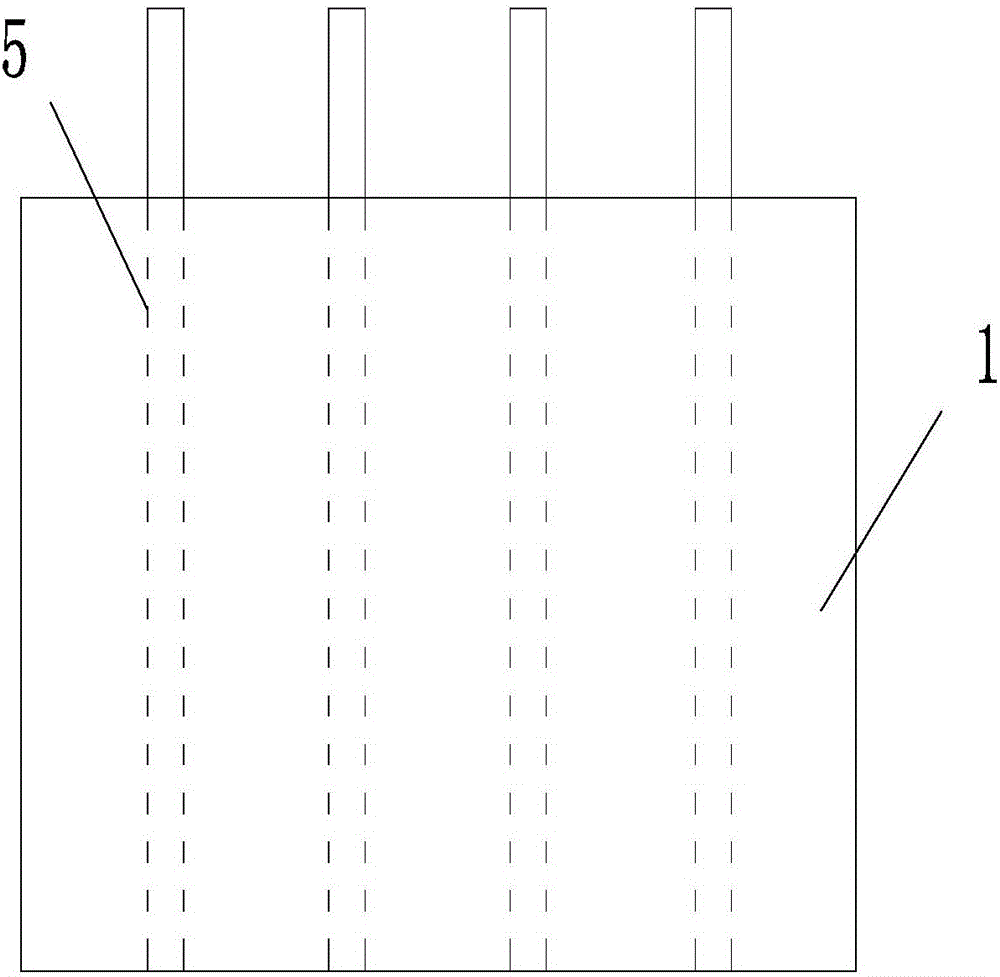

[0020] Such as Figure 1 to Figure 3 As shown, a lithium battery that is convenient for the exhaust of the cell coil 1 includes a battery casing, and the cell coil 1 is arranged inside the battery casing. The upper cover plate of the casing protrudes; the cell coil 1 includes a positive coil 2, a negative coil 3 and a separator, and the separator is located between the positive coil 2 and the negative coil 3;

[0021] The diaphragm includes two lithium battery diaphragms 4 arranged on the left and right. The lithium battery diaphragm 4 is an integrated structure of ultra-high molecular polyethylene. The lithium battery diaphragm 4 is provided with several transversely penetrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com