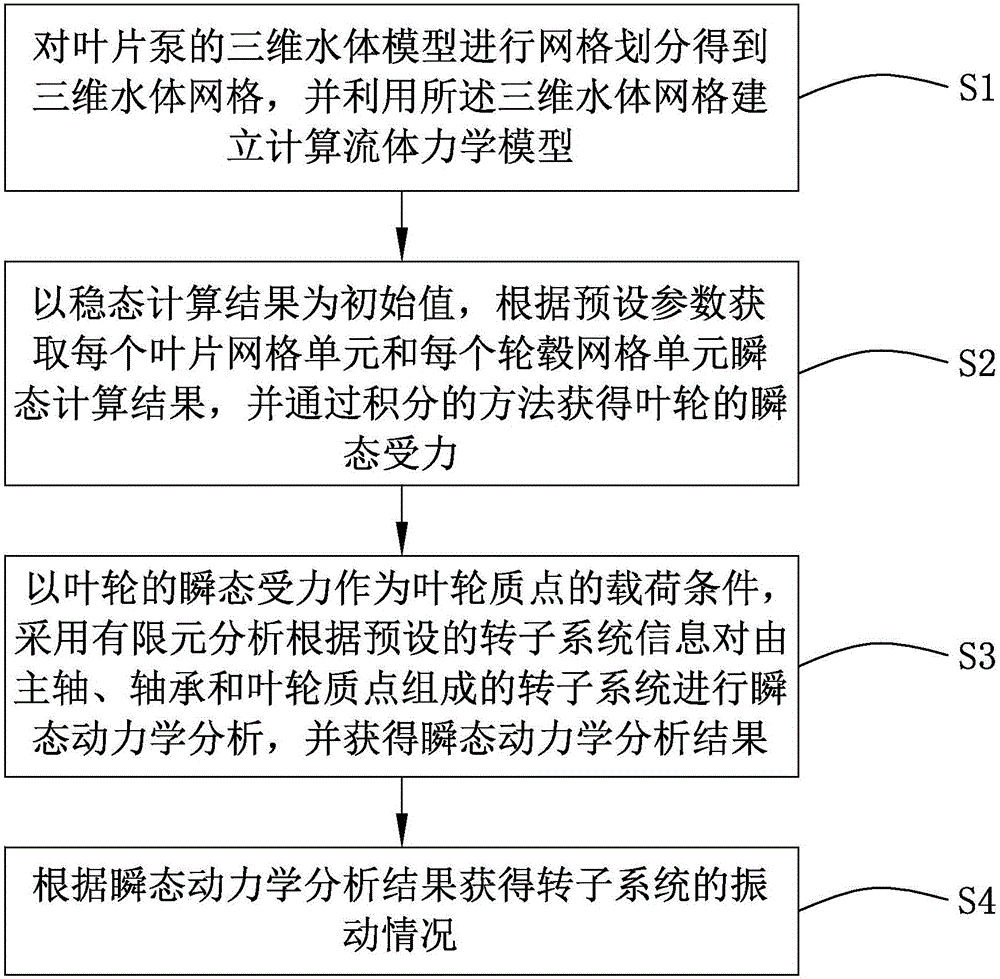

Vibration simulation analysis method and device of vane pump rotor system

A simulation analysis, vane pump technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as no known information disclosure application cases, and achieve the effect of meeting design requirements and high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0110] Further, please refer to Figure 17 , is a functional block diagram of the fourth embodiment of the vibration simulation analysis device for the vane pump rotor system provided by the present invention. Based on the first embodiment of the vibration simulation analysis device of the vane pump rotor system of the present invention, the transient force acquisition module 30 of the impeller includes:

[0111] A steady-state calculation unit 31, configured to perform steady-state calculations according to the computational fluid dynamics model, and obtain steady-state calculation results;

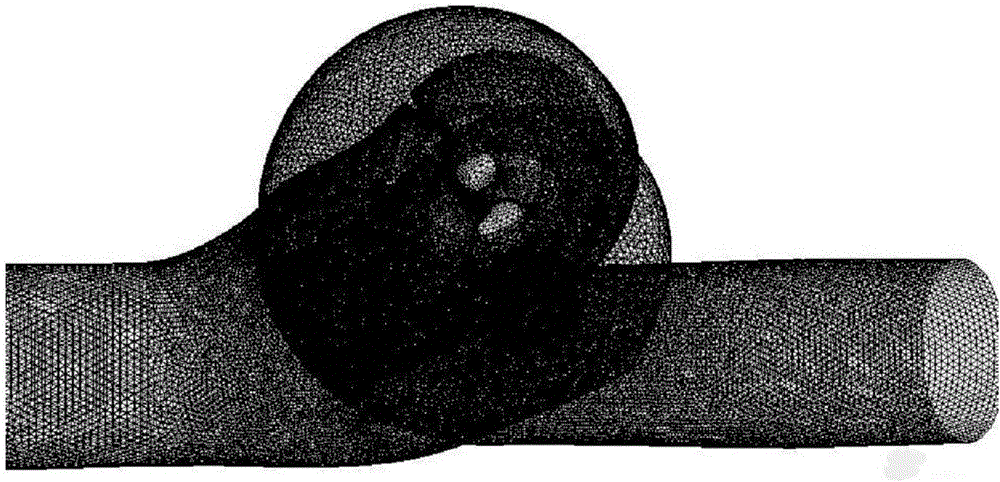

[0112] The transient calculation unit 33 is used to calculate the surface hydraulic pressure distribution of each blade grid unit and each hub grid unit according to the computational fluid dynamics model, and obtain the axial transient force of each blade grid unit on the horizontal plane and the vertical plane and the axial transient force on the horizontal plane and vertical plane of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com