Multidisciplinary Optimal Design Method for Heavy Metal Axial Flow Pumps

An optimized design and axial-flow pump technology, applied in design optimization/simulation, geometric CAD, special data processing applications, etc., can solve the problems of no heavy metal pumps, less research on heavy metal pumps, etc., and achieve the effect of good safety characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

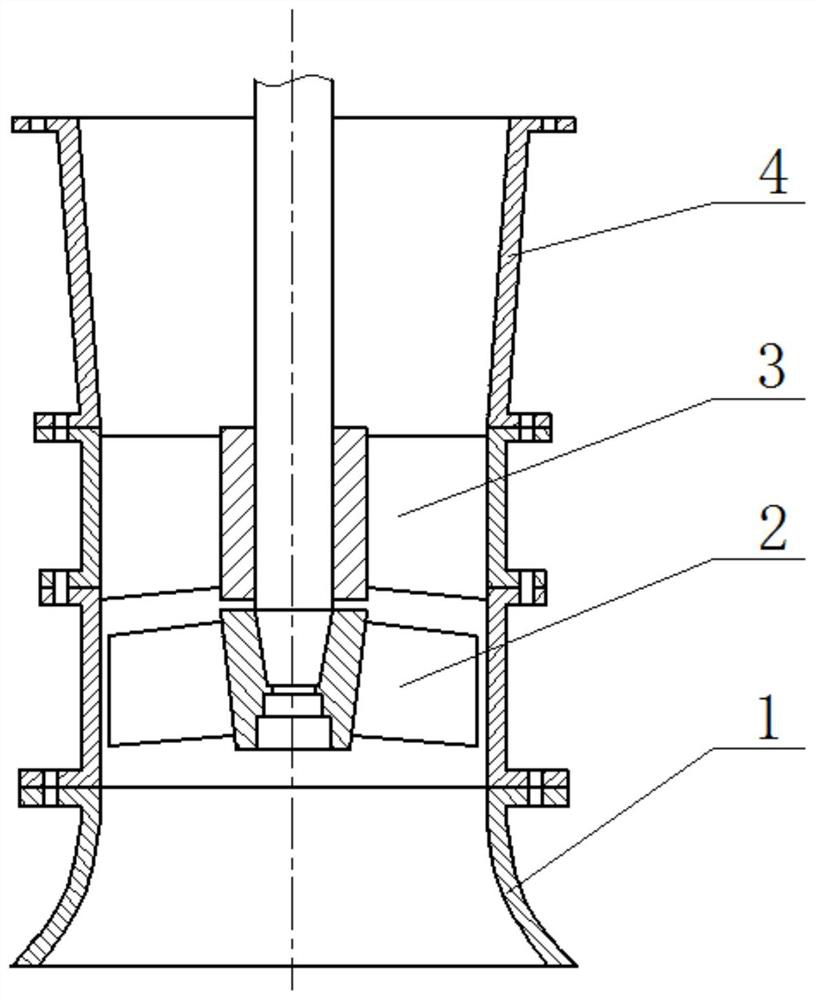

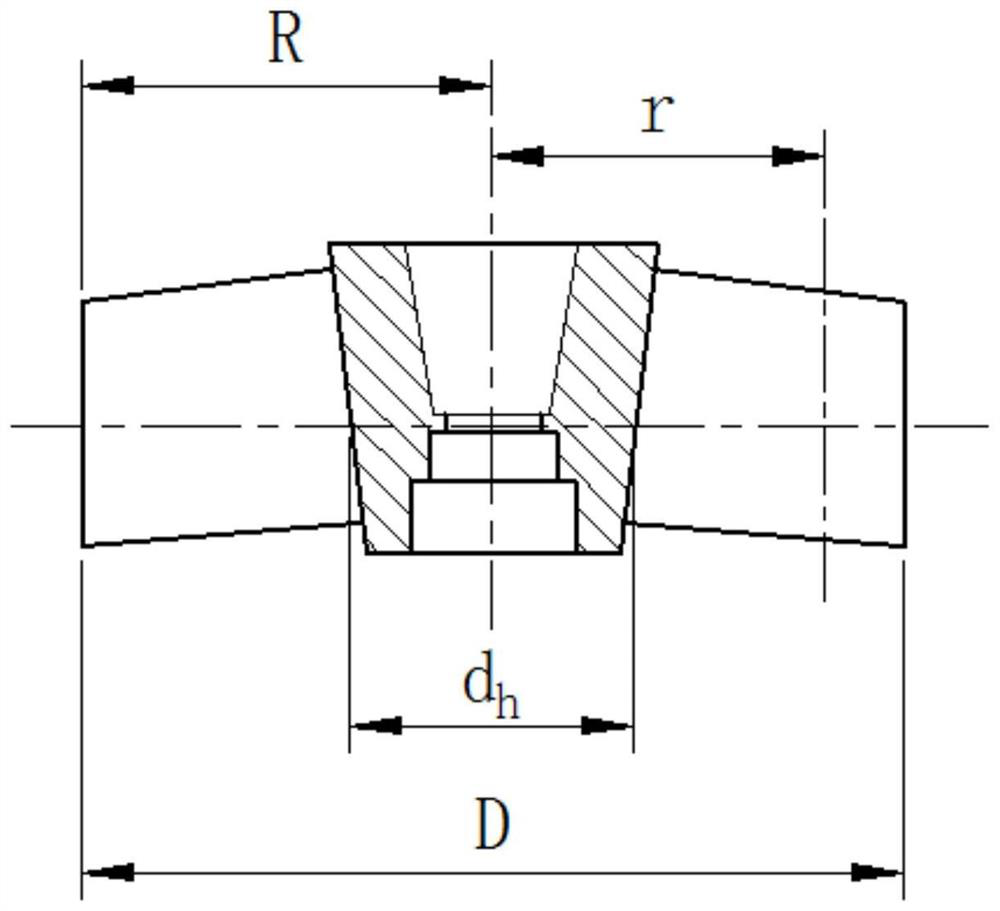

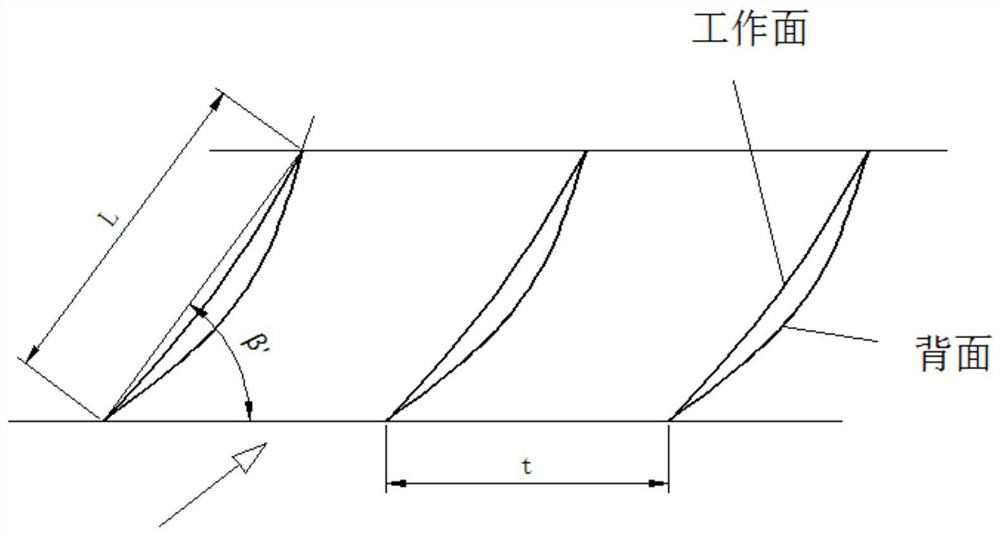

[0071] Figure 1 to Figure 5 It is a schematic structural diagram of an embodiment of the present invention, Figure 6 and Figure 7 It is a flow chart of the multidisciplinary optimization design of the present invention. The present invention is a multi-disciplinary optimization design method for a heavy metal axial flow pump. The heavy metal axial flow pump works under the extreme conditions of high temperature, and the conveying medium is high temperature liquid metal. It is mainly composed of four parts: suction chamber, impeller, guide vane and diffusion pipe. , which is characterized in that the optimization design process of the heavy metal axial flow pump is modularized by adopting a multidisciplinary optimization method, which is divided into five modules: hydraulic design module, structural modeling optimization module, CFD calculation module, fluid-solid thermal coupling module and system optimization module, Among them, the hydraulic design module is to use the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com