A multi-variable and multi-objective parallel optimization method for high temperature pump design

An optimization method and multi-objective technology, applied in the field of optimal design of high-temperature pumps, can solve problems such as single factor and achieve the best effect of safety characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below through specific embodiments.

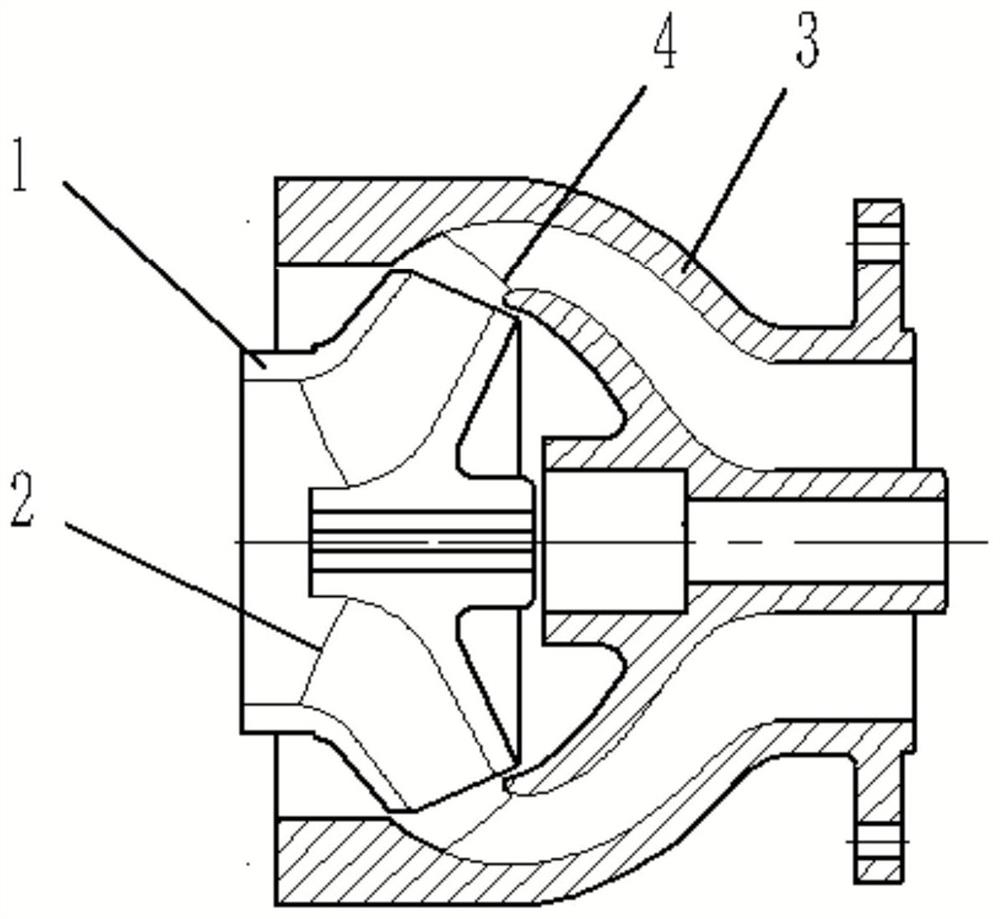

[0040] figure 1 It is a structural diagram of the impeller and guide vane of an embodiment of the present invention. Based on the multi-variable and multi-objective parallel optimization method, the high-temperature pump impeller and guide vane are optimized. The high-temperature pump mainly works under the extreme working condition of >300 degrees Celsius. , modularize the optimization process of the high temperature pump, the first module is the experimental design module, the second module is the multi-objective parallel optimization module, and the third module is the optimal analysis and redesign module; the specific methods are as follows:

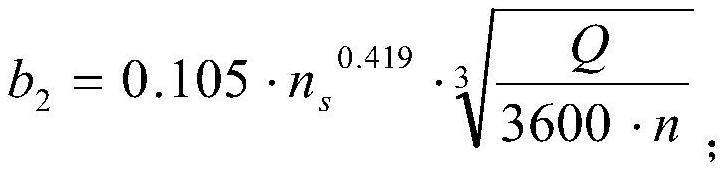

[0041] Design Parameters Ⅰ Impeller outlet diameter D 2 , Design parameter II blade inlet placement angle β 1 , Design parameter III blade outlet placement angle β 2 , Design parameter IV impeller outlet inclination angle γ, design paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com