Test method for magnetorheological-fluid floating property and tester thereof

A magnetorheological fluid, suspension stabilization technology, applied in the direction of particle suspension analysis, suspension and porous material analysis, instruments, etc., can solve the problem of interfering with the settlement process of ferromagnetic particles, disturbing the sedimentation movement of magnetorheological fluid particles, cumbersome operation, etc. problems, to achieve the effect of automatic scanning measurement, labor cost saving and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

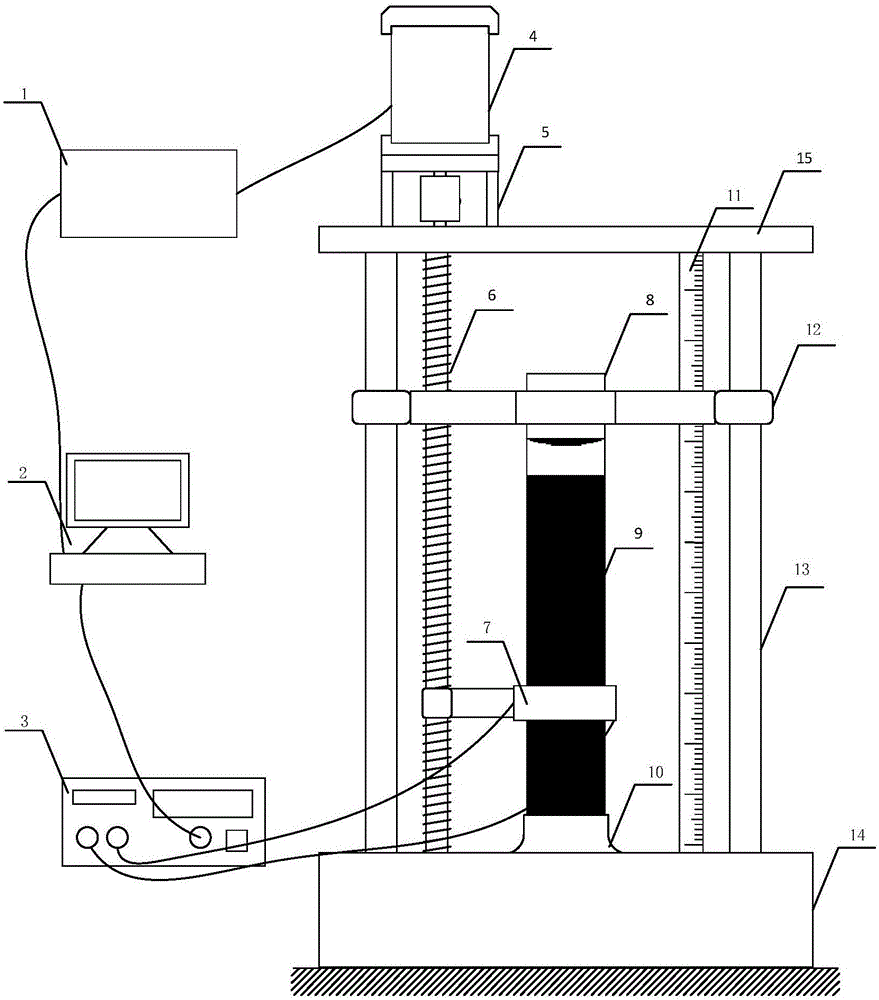

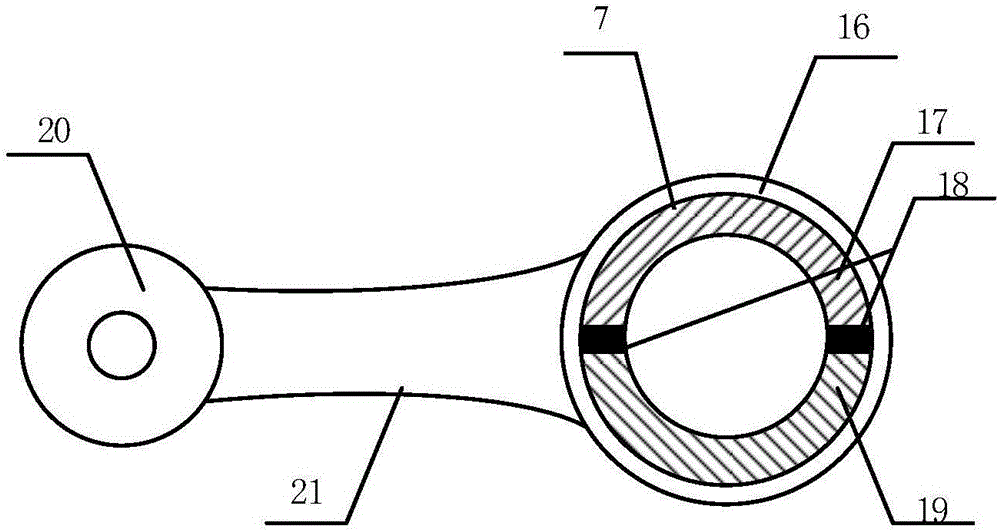

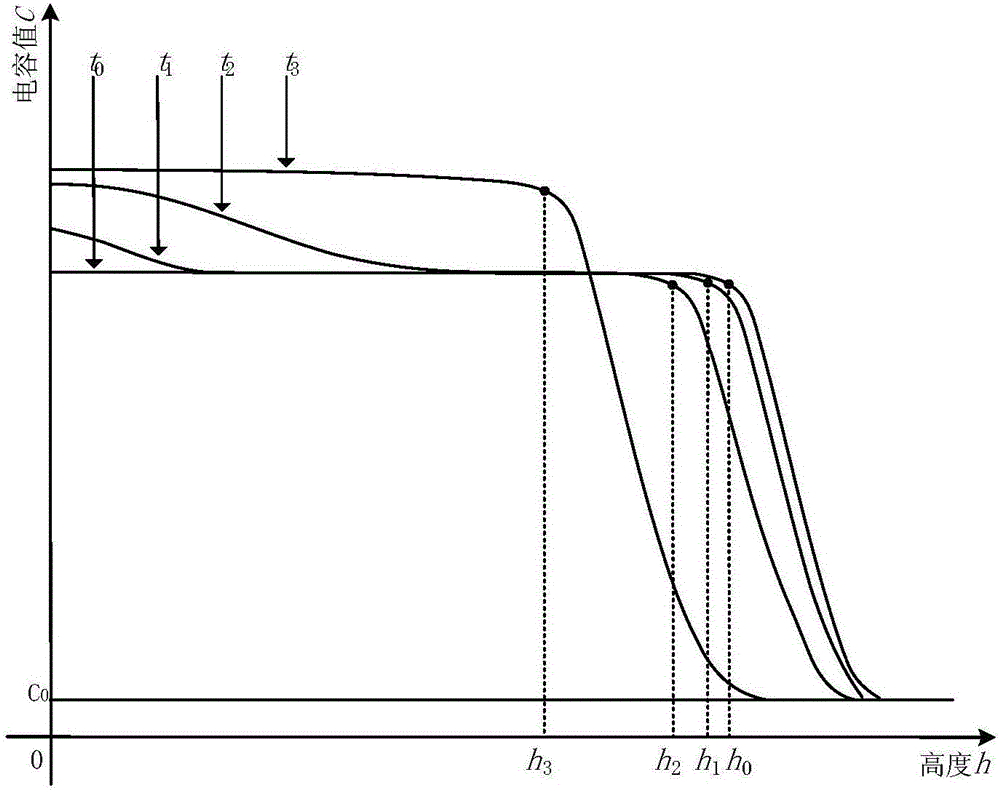

[0034] figure 1 It is a structural schematic diagram of the magnetorheological fluid suspension stability performance tester of the present invention, figure 2 It is a structural schematic diagram of a capacitive sensor in the present invention, image 3 is the capacitance value-height relationship diagram at different times, Figure 4It is a control flow chart for testing the magnetorheological fluid suspension stability performance tester of the present invention. The magnetorheological fluid suspension stability test method of the present embodiment utilizes the capacitive sensor to measure the sedimentation rate of the magnetorheological fluid; when using the capacitive sensor to test the magnetorheological fluid, there is no external magnetic field in the vertical direction, and the magnetic field in the horizontal direction is very Weak, negligible, effectively controlling the influence of the external magnetic field on the suspension stability of the magnetorheologic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com