Hydrogen permeation measurement system

A test system and permeability technology, which is applied in the field of hydrogen permeation measurement device system, can solve problems such as the inability to combine development of different technologies, the difficulty of characterizing the comprehensive performance of materials, and the inability to accurately measure permeability, so as to achieve accurate and reliable test structures. Test analysis, good sealing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

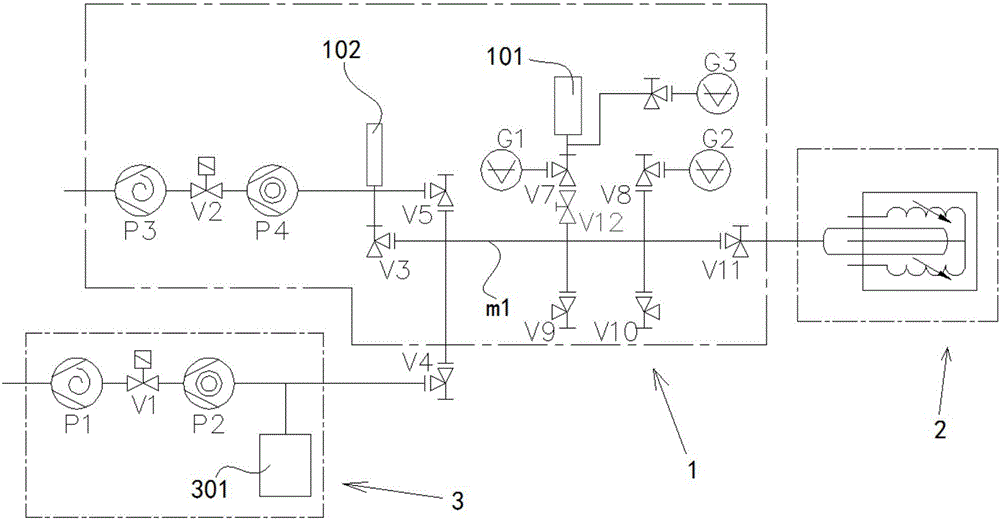

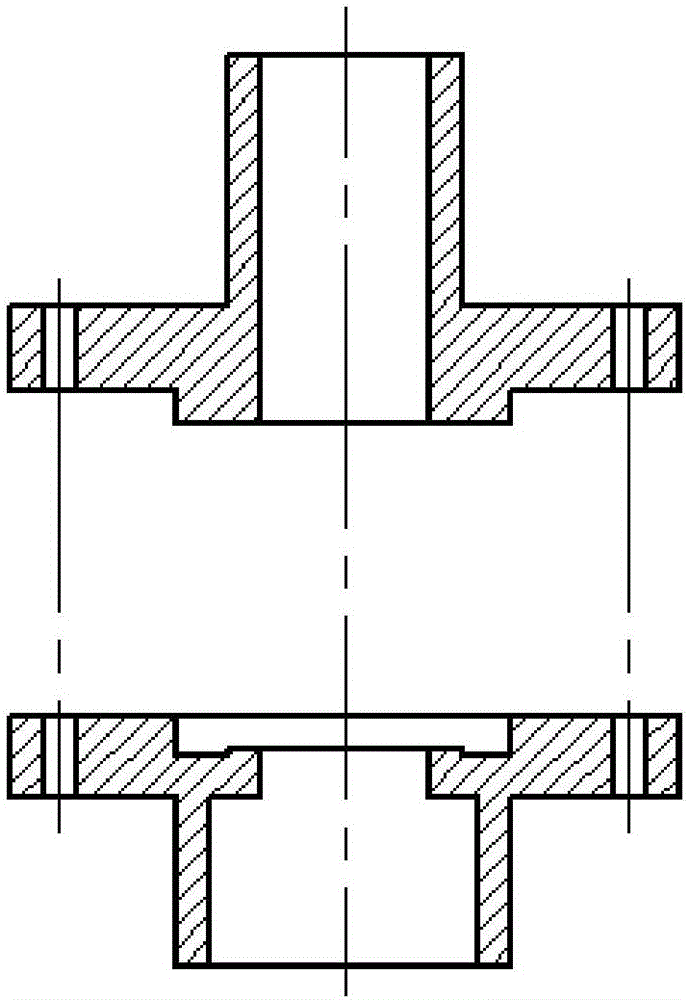

[0041] Such as figure 1 The hydrogen permeability test system shown includes a heating temperature control furnace unit 2 with a fixed structure inside to fix the stainless steel sample to be tested (it can also be other sample materials). After the material is fixed, there is a test gas source inlet. The other side is the permeate side, and the detection pipeline is connected to the high-vacuum pipeline unit 1. The connection form is as follows figure 2 Shown. The material to be tested is clamped by the high-sealing tool for membrane penetration test, and the material to be tested is clamped in figure 2 The middle groove surface of the tooling shown enhances the stability of clamping and fixing, improves the sealing and balance performance of the material, and can realize more accurate testing.

[0042] Therefore, it is preferred that the tool test part of the present invention has mutually matched groove clamping parts for clamping the sample to be tested.

[0043] The overal...

Embodiment 2

[0052] Such as figure 1 The main structure of the hydrogen permeability test system device shown is the same as that of Example 1. Furthermore, the sample container is a calibrated constant volume container. The sample container has two functions: (one is) for materials with a higher hydrogen permeation rate, when hydrogen permeates from the high pressure side, more gas permeates into the sample container. Under constant temperature conditions, by measuring the pressure change in the sample container, the amount of permeated gas that changes with time can be obtained. Let the overall pressure change within a certain range to calculate the hydrogen permeability of the tested sample. (The second function of the sample container is) when the hydrogen permeation rate of the measured material is very slow, the gas pressure in the sample container does not change significantly, making the reading error increase, so the measured hydrogen permeation rate is not accurate, and RGA mass s...

Embodiment 3

[0056] Such as figure 1 The hydrogen permeability test system shown includes a heating temperature control furnace unit with a fixed structure inside to fix the stainless steel sample to be tested (other sample materials can also be used). The stainless steel material is fixed on one side with the test gas source inlet, and the other One side is the permeate side, and the permeate side is connected to the vacuum piping system and further connected to the vacuum piping unit. The heating temperature control furnace unit can control the ambient temperature of the tooling part of the material to be tested to continuously change within the temperature range of 77K~1100K, and the temperature accuracy is ±0.5℃. The vacuum piping system is connected to the main pipeline of the vacuum piping unit. A sample container, a hydrogen standard leak and a first molecular pump are respectively connected on both sides of the main pipeline, and a first scroll vacuum pump is connected to the back en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com