Sealed shale gas flow testing method and device

A technology for testing devices and air intake devices, which is applied in measurement devices, suspension and porous material analysis, instruments, etc., can solve the problems of underestimating permeability, ignoring adsorption effects, and inability to characterize seepage characteristics, achieving a high degree of automation and data The effect of automatic monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

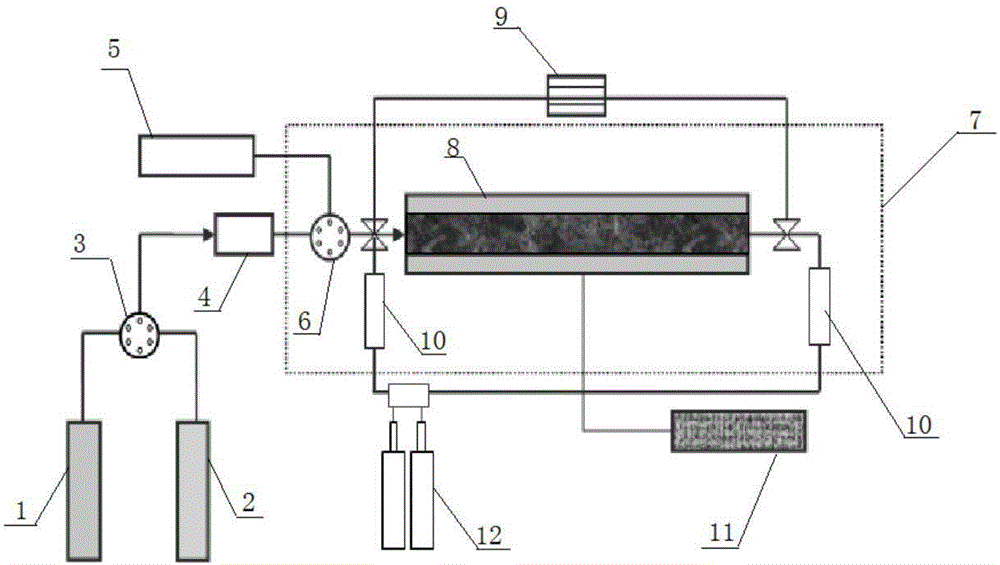

[0034] Such as figure 1 As shown, a closed test device for shale gas flow includes a high-pressure nitrogen gas inlet device 1, a high-pressure natural gas inlet device 2, a first six-way valve 3, a booster pump 4, a second six-way valve 6, an evacuation Device 5, constant temperature box 7, core flow model 8, differential pressure sensor 9, buffer 10, ring pressure control pump 11 and bidirectional displacement pump 12;

[0035] The high-pressure nitrogen inlet device 1 and the high-pressure natural gas inlet device 2 are connected to the second six-way valve 6 after passing through the first six-way valve 3 and the boos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com