Detection device for straightness of scraper conveyer and detection method

A technology of scraper conveyor and detection device, which is applied in the direction of measuring device, signal transmission system, instrument, etc., can solve the problems of low visibility of visual recognition underground, camera calibration, low efficiency of means, etc., and achieve efficient and accurate detection work and detection The effect of small error and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

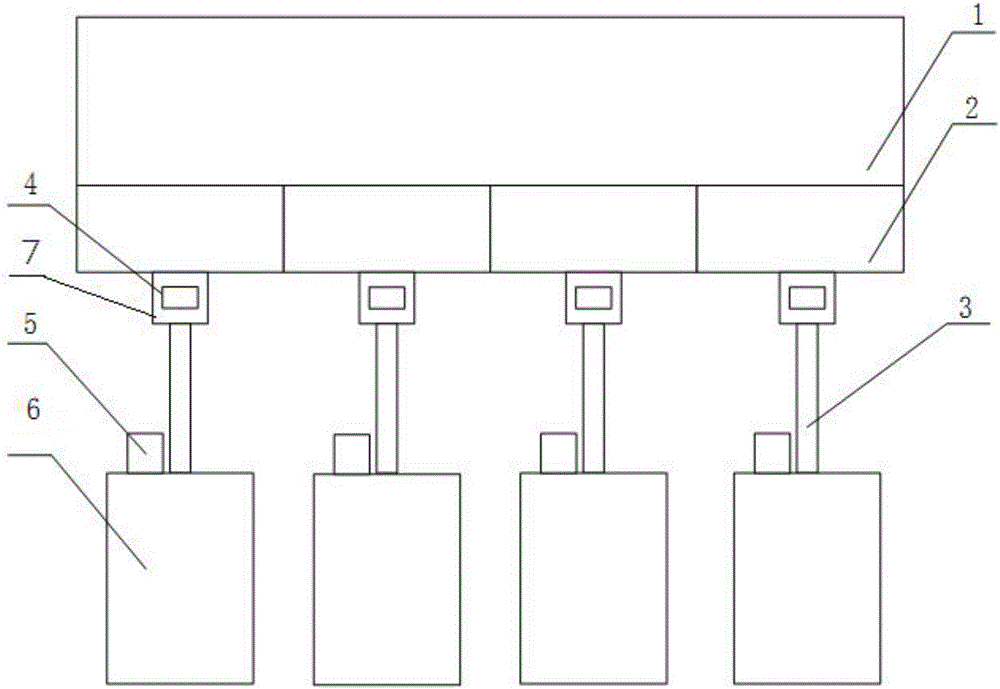

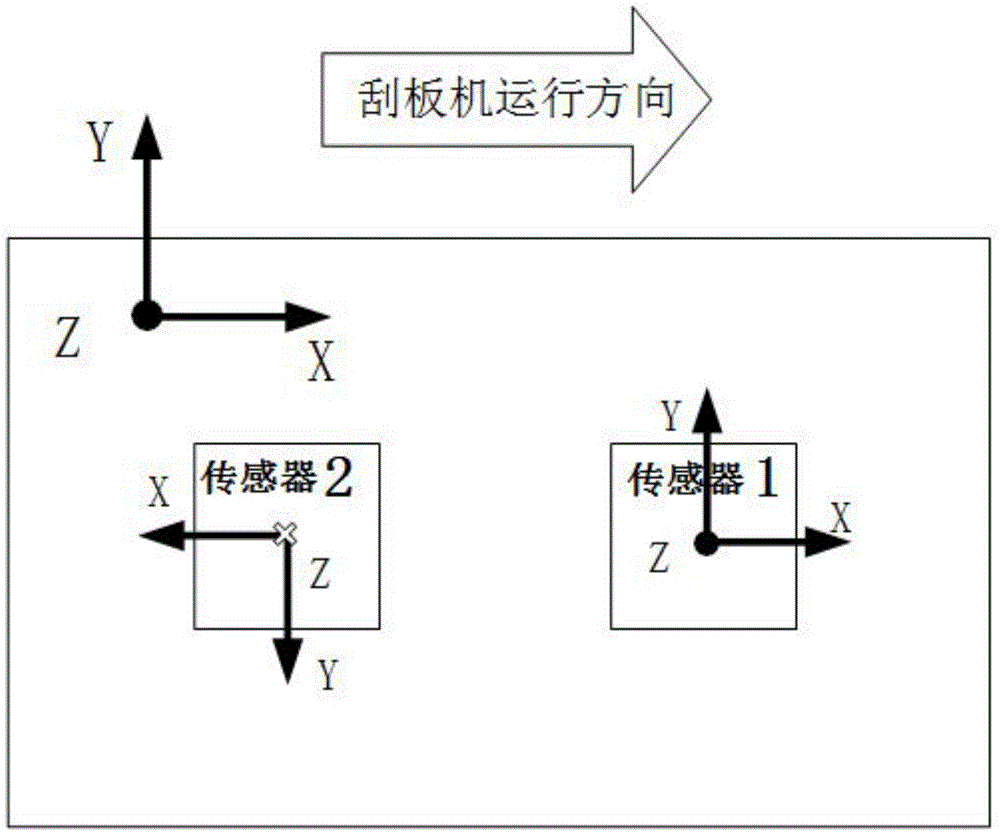

[0031] Such as figure 1 As shown, a detection device for the straightness of a scraper conveyor, the detection device includes a data acquisition unit, a communication unit, a data processing unit, a data storage unit, an alarm unit and a power supply module arranged in the protective cover 4, the The data acquisition unit is used to collect the triaxial acceleration, triaxial angular velocity and triaxial magnetic induction intensity data of the middle groove 2 of each section of the scraper conveyor during the process of being pushed, and communicate with the data processing unit through the WiFi module; the communication The unit is used to establish communication between adjacent detection devices through the WiFi module provided therein; the data processing unit is set corresponding to the data acquisition unit, and is used to receive and process the data collected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com