Air leakage control system of air preheater

An air preheater and control system technology, which is applied in the directions of combustion air/fuel supply, non-flammable liquid/gas transportation, heat exchange equipment, etc., can solve the problems of low control accuracy, easy damage, and inability to maintain online Achieve the effect of improving control efficiency and solving low control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

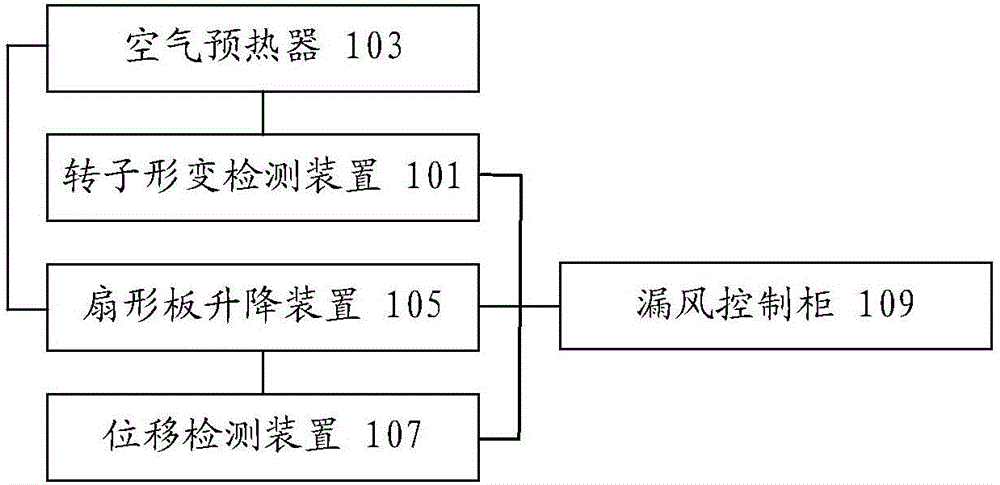

[0024] According to an embodiment of the present invention, an embodiment of an air leakage control system for an air preheater is provided, figure 1 It is a structural schematic diagram of an optional air leakage control system of an air preheater according to an embodiment of the present invention, as shown in figure 1 As shown, the air leakage control system of the air preheater includes:

[0025] The rotor deformation detection device 101 is connected with the air preheater 103 and is used to detect the deformation of the rotor of the air preheater; the sector plate lifting device 105 is connected with the air preheater 103 and is used for adjusting The fan-shaped plate is lifted and lowered; the displacement detection device 107 is connected with the fan-shaped plate lifting device 105, and is used to detect the downward displacement of the fan-shaped plate; the air leakage control cabinet 109 is connected with the rotor deformation detection device 101, the fan-shaped pl...

Embodiment 2

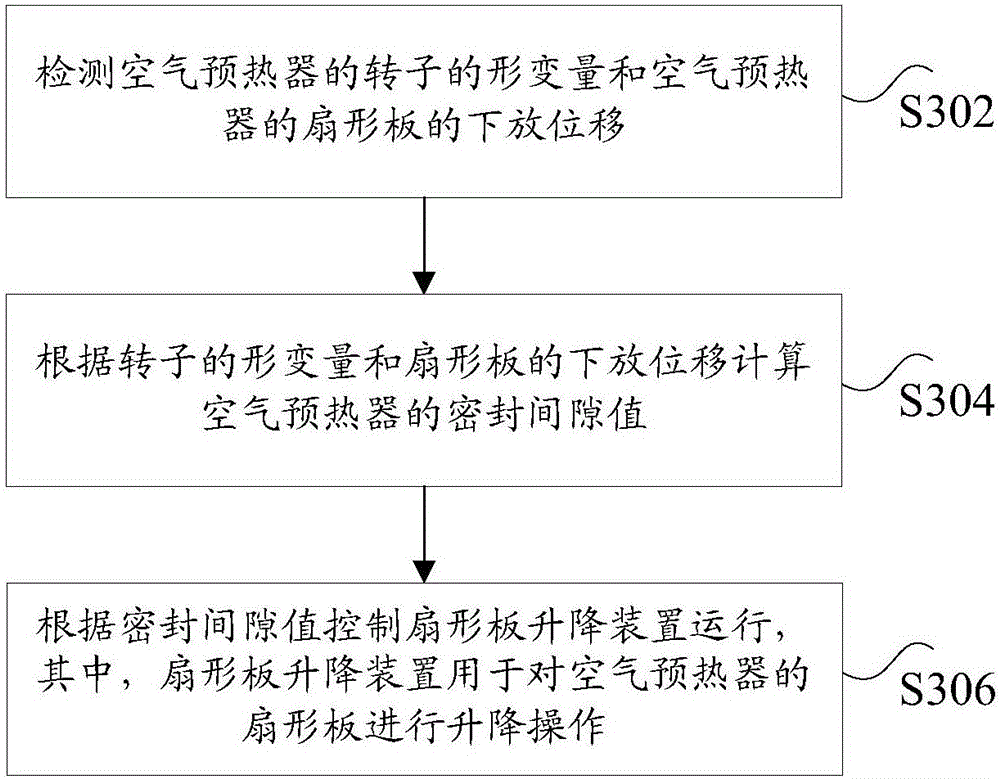

[0048] According to an embodiment of the present invention, an embodiment of an air leakage control method for an air preheater is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be implemented in a computer system such as a set of computer-executable instructions and, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0049] image 3 is a schematic flow chart of an air leakage control method for an air preheater according to an embodiment of the present invention, as shown in image 3 As shown, the method includes the following steps:

[0050] Step S302, detecting the deformation of the rotor of the air preheater and the lowering displacement of the sector plates of the air preheater;

[0051] Step S304, calculating the sealing gap value of the air preheater according to the deformation of the rotor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com