Soil conditioner for repairing farmland heavy metal pollution and manufacturing method thereof

A soil conditioner and heavy metal technology, applied in the field of pollution remediation, can solve the problems of complex process, unsolved soil heavy metal pollution, high production cost, etc., achieve no chemical substance addition, reduce soil heavy metal toxicity, and improve fertilizer and water use efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

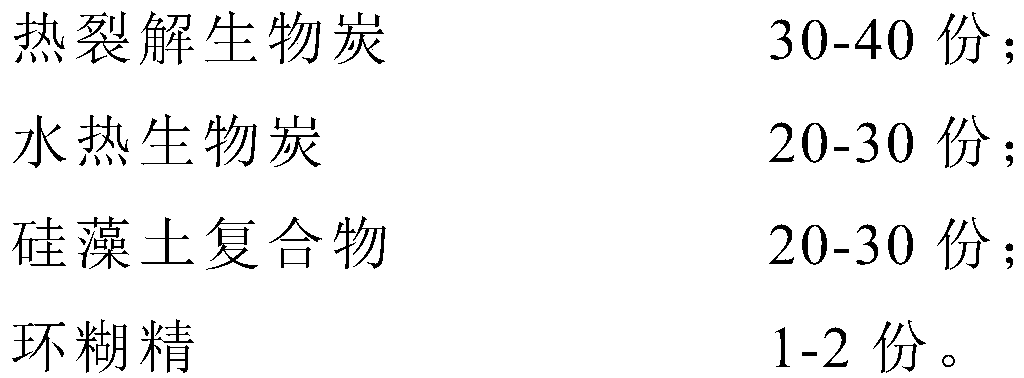

[0030] A soil conditioner for repairing heavy metal pollution in farmland, including 30kg of pyrolysis biochar, 20kg of hydrothermal biochar, 20kg of diatomaceous earth compound and 1kg of cyclodextrin.

[0031] In this example, the diatomite compound is made by mixing diatomite powder and chitosan at a mass ratio of 3:1, and the pyrolysis biochar is made of hickory cattail charcoal at 450-600°C under inert gas conditions. It is obtained by calcining, and the hydrothermal biochar is obtained under high-pressure hydrothermal conditions at 180-240°C.

Embodiment 2

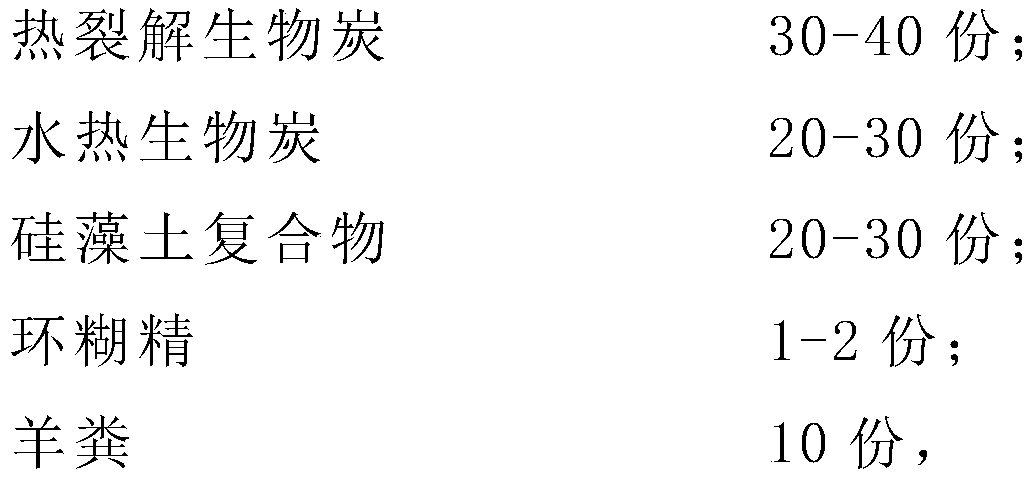

[0033] This example is basically the same as Example 1, except that this soil conditioner includes 40 parts of pyrolysis biochar, 30 parts of hydrothermal biochar, 30 parts of diatomaceous earth compound and 2 parts of cyclodextrin.

Embodiment 3

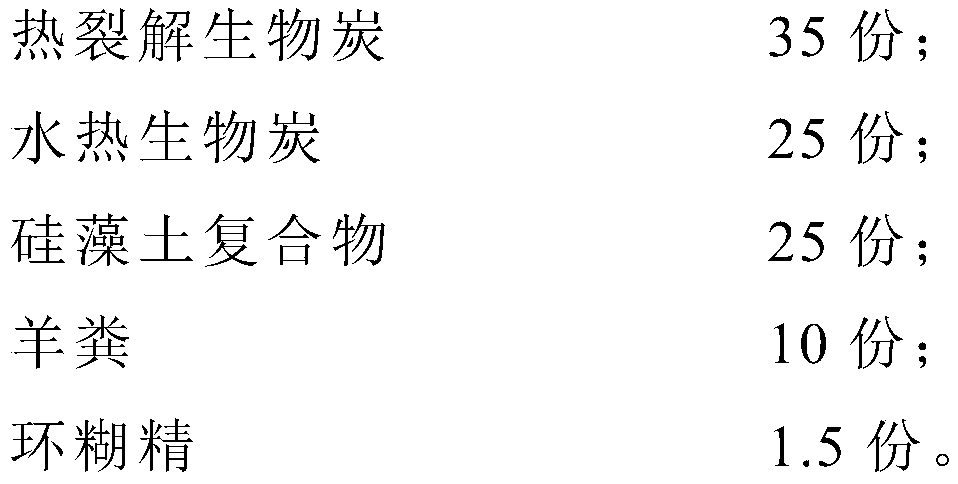

[0035] This example is basically the same as Example 1, except that this soil conditioner includes 35kg of pyrolysis biochar, 25kg of hydrothermal biochar, 25kg of diatomaceous earth compound, 10kg of sheep manure and 1.5kg of cyclodextrin. The moisture content of the sheep manure of the present embodiment is 5-7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com