A kind of composite blowing agent and its application

A technology of composite foaming agent and foam stabilizer, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of reducing the amount of surfactant added, difficulty in oil-water emulsification and processing, and poor stability of foaming agent. , to achieve the effect of small dosage, high stability and good foaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031]In the present invention, there is no special requirement for the preparation method of the anionic oligomeric surfactant having the structure shown in formula (I), and various methods that those skilled in the art can think of can be adopted, preferably comprising: in the Mannich reaction Under conditions, alkali, taurine, formaldehyde and alkylphenol are carried out contact reaction in the mixed solvent that organic solvent and water form, and wherein, described alkali is lithium hydroxide, sodium hydroxide and potassium hydroxide at least One, the alkylphenol is p-alkylphenol, and the molar ratio of taurine, alkali, formaldehyde and alkylphenol is 1:1-3:2-3:1-2.

[0032] According to the preparation method of the present invention, wherein, preferably, under Mannich reaction conditions, the alkali, taurine and formaldehyde are first dissolved in a mixed solvent formed of an organic solvent and water, and then an alkylphenol is added to carry out contact reaction.

[...

preparation example 1

[0045] Use ethylene glycol monomethyl ether and water as a mixed solvent (volume ratio of 7:3), the amount of the mixed solvent is 200mL, add 64g of potassium hydroxide, 125g of taurine and 63g of formaldehyde to dissolve completely Finally, 275g of p-nonylphenol was added, reacted at 25°C for 6 hours, then heated to reflux, and after reflux for 4h, the solvent was evaporated at 70°C and 0.03MPa to obtain anionic oligomeric surfactant A1.

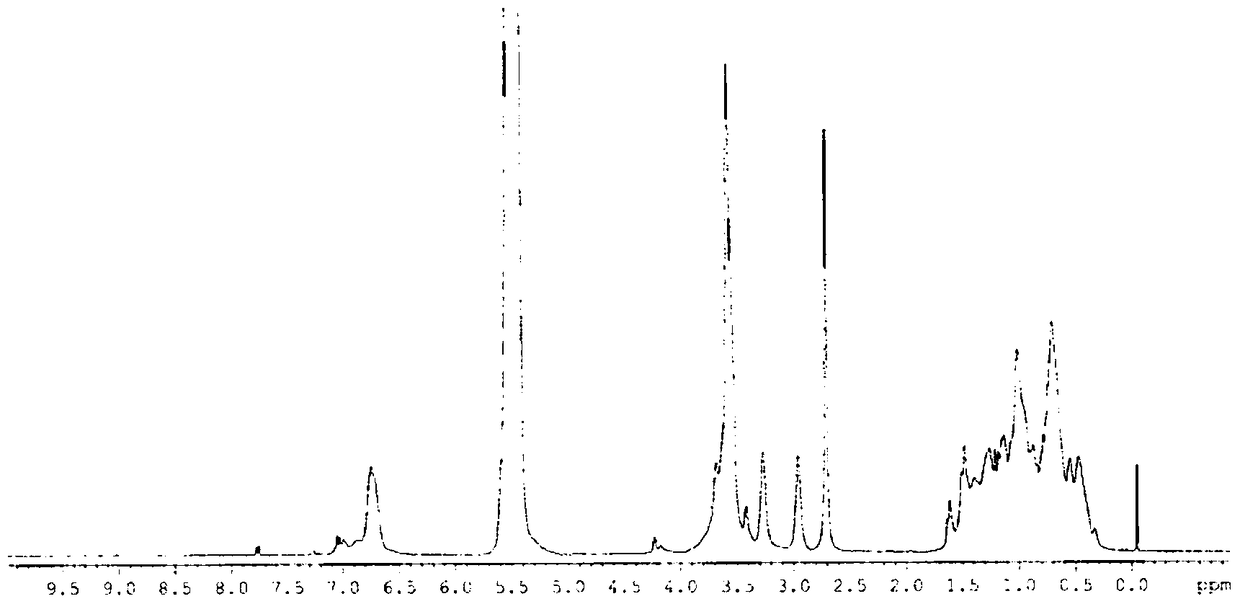

[0046] The hydrogen spectrum, carbon spectrum and mass spectrometry were carried out on A1, and the results of the hydrogen spectrum, carbon spectrum and mass spectrometry of A1 were as follows: figure 1 , figure 2 with image 3 As shown, it can be inferred that the structural formula of A1 is as follows (that is, equivalent to structural formula (I), n is 3, R is nonyl, and M is K + ).

[0047]

preparation example 2

[0049] With tetrahydrofuran and water as a mixed solvent (volume ratio of 4:1), the amount of the mixed solvent is 150mL, 48g of sodium hydroxide, 125g of taurine and 63g of formaldehyde are added thereto, after completely dissolving, add 275g of For p-octylphenol, react at 30°C for 7 hours, then heat to reflux, and after reflux for 6 hours, evaporate the solvent at 50°C and 0.01MPa to obtain anionic oligomeric surfactant A2.

[0050] Carry out hydrogen spectrum, carbon spectrum and mass spectrometry respectively to A2, hydrogen spectrum, carbon spectrum and mass spectrogram are not listed, deduce the structure of A2 through the spectrogram of determination as shown in formula (I), wherein, n is 2, R is octyl, M is Na + .

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com