Lignin modified PHA biodegradable plastic and preparing method thereof

A biodegradable plastic and lignin technology, which is applied in the field of lignin-modified PHA biodegradable plastics and its preparation, can solve the problems of high-cost PHA, etc., and achieve the effects of convenient operation, cheap and easy-to-obtain raw materials, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 Preparation of lignin-modified PHA biodegradable plastics

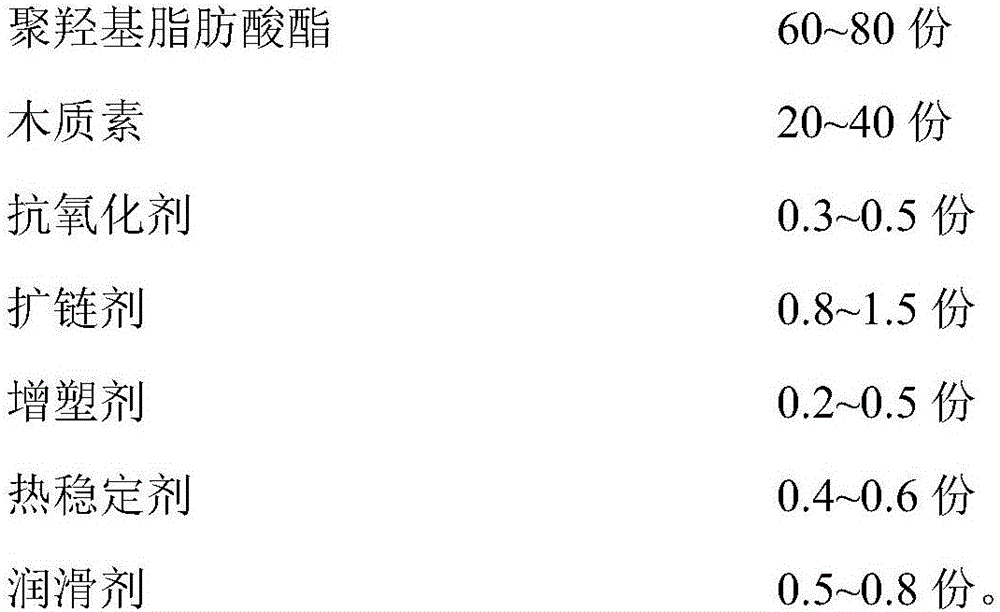

[0032] (1) In terms of parts by weight, the proportioning ratio of each raw material used is as follows:

[0033]

[0034] (2) Concrete preparation method, comprising the following steps:

[0035] (1) Dry a certain amount of PHA and lignin powder (200 mesh) at 25°C and 0-5000Pa for 2.5h;

[0036] (2) Add dried PHA, lignin powder, 1,6-hexanediol, butyl hydroquinone, triethyl citrate, epoxidized soybean oil, calcium stearate into the high mixer to control the material The temperature is 100-105°C, mixed for 15 minutes, and the speed is 900r / min;

[0037] (3) Extruding and granulating the obtained mixed material through a twin-screw extruder, controlling the extrusion temperature to be 150-160° C. to obtain lignin-PHA composite plastic particles;

[0038] (4) The lignin-PHA composite plastic is blown into a film, and the injection molding temperature is controlled at 140-170° C. to prepare vario...

Embodiment 2

[0039] Embodiment 2 Preparation of lignin-modified PHA biodegradable plastics

[0040] (1) In terms of parts by weight, the proportioning ratio of each raw material used is as follows:

[0041]

[0042]

[0043] (2) Concrete preparation method, comprising the following steps:

[0044] (1) Dry a certain amount of PHA and lignin (200 mesh) at 25°C and 0-5000Pa for 3 hours;

[0045] (2) Add dry PHA, lignin, acetyl tri-n-butyl citrate, resorcinol dihydroxyethyl ether, butyl hydrodiphenol, epoxidized soybean oil, calcium stearate into the high mixer , control the material temperature to 110°C, mix for 20 minutes, and the speed is 1000r / min;

[0046] (3) extruding and granulating the obtained mixed material through a twin-screw extruder, controlling the extrusion temperature to be 160-170° C. to obtain lignin-PHA composite plastic particles;

[0047] (4) The lignin-PHA composite plastic is blown into a film, and the injection molding temperature is controlled at 150-160° C. t...

Embodiment 3

[0048] Example 3 Preparation of lignin-modified PHA biodegradable plastics

[0049] (1) In terms of parts by weight, the proportioning ratio of each raw material used is as follows:

[0050]

[0051] (2) Concrete preparation method, comprising the following steps:

[0052] (1) Dry a certain amount of PHA and lignin (200 mesh) at 25°C and 0-5000Pa for 3 hours;

[0053] (2) Add dried PHA, lignin, maleic anhydride, glycerol triacetate, butyl hydrodiphenol, 1,4-butanediol, zinc stearate into the high mixer to control the material temperature at 105°C, mix for 25 minutes, and the speed is 1000r / min;

[0054] (3) extruding and granulating the obtained mixed material through a twin-screw extruder, controlling the extrusion temperature to be 180-190° C. to obtain lignin-PHA composite plastic granules;

[0055] (4) The lignin-PHA composite plastic is blown into a film, and the injection molding temperature is controlled at 160-170° C. to prepare various lignin-modified PHA biodeg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com