Seal ring for special fluororubber motor for nuclear power and preparation method of seal ring

A technology of fluorine rubber and nuclear power, which is applied in the field of special fluorine rubber motor sealing rings for nuclear power and its preparation. It can solve the problems of many inorganic fillers, weak high temperature resistance, and affecting the mechanical properties of the product, and achieve strong interface bonding strength and good Performance, perfect effect of cross-linked network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

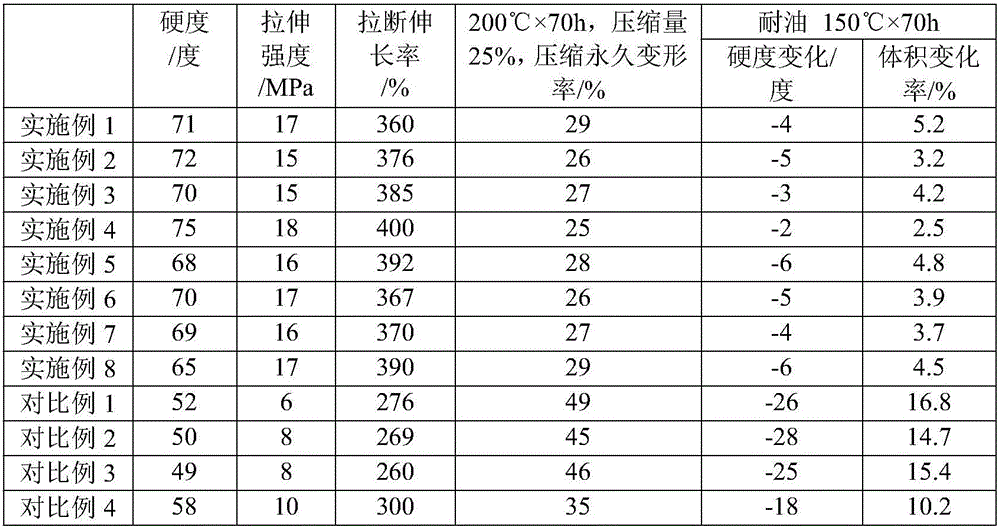

Examples

Embodiment 1

[0032] A special fluororubber motor sealing ring for nuclear power, comprising the following raw materials in parts by weight: 85 parts of fluororubber, 8 parts of acid absorbing agent, 2 parts of compound vulcanizing agent, 10 parts of reinforcing agent and 1 part of auxiliary agent.

[0033] The fluororubber is a mixture of fluororubber 2463, fluororubber 2602 and fluororubber 2603 at a weight ratio of 0.5:0.5:1.

[0034] The acid absorbing agent is a mixture of calcium oxide and magnesium oxide in a weight ratio of 1:2.

[0035] Among them, the composite vulcanizing agent is bisphenol AF, benzyl triphenyl phosphorus chloride, No. 3 vulcanizing agent and No. 5 vulcanizing agent mixed in a weight ratio of 2:2:2:1.

[0036] The reinforcing agent is carbon black N990.

[0037] Wherein the auxiliary agent is palm wax.

[0038] A preparation method of a special fluororubber motor sealing ring for nuclear power, comprising the following steps:

[0039] (1) Premixing: Mix the ac...

Embodiment 2

[0045] A special fluororubber motor sealing ring for nuclear power, comprising the following raw materials in parts by weight: 86 parts of fluororubber, 7.5 parts of acid absorbing agent, 2.5 parts of compound vulcanizing agent, 9.5 parts of reinforcing agent and 1.2 parts of auxiliary agent.

[0046] The fluororubber is a mixture of fluororubber 2463, fluororubber 2602 and fluororubber 2603 at a weight ratio of 0.8:0.8:1.

[0047] The acid absorbing agent is a mixture of calcium oxide and magnesium oxide in a weight ratio of 1:1.

[0048] The composite vulcanizing agent is made by mixing bisphenol AF, benzyl triphenylphosphine chloride, No. 3 vulcanizing agent and No. 5 vulcanizing agent in a weight ratio of 3:2:3:1.

[0049] The reinforcing agent is carbon black N990.

[0050] Wherein the auxiliary agent is palm wax.

[0051] A preparation method of a special fluororubber motor sealing ring for nuclear power, comprising the following steps:

[0052] (1) Premixing: Mix the a...

Embodiment 3

[0058] A special fluororubber motor sealing ring for nuclear power, comprising the following raw materials in parts by weight: 87 parts of fluororubber, 7 parts of acid absorbing agent, 3 parts of compound vulcanizing agent, 9 parts of reinforcing agent and 1.4 parts of auxiliary agent.

[0059] The fluororubber is a mixture of fluororubber 2463, fluororubber 2602 and fluororubber 2603 at a weight ratio of 0.9:0.8:1.

[0060] The acid absorbing agent is a mixture of calcium oxide and magnesium oxide in a weight ratio of 3:2.

[0061] Among them, the compound vulcanizing agent is bisphenol AF, benzyl triphenyl phosphorus chloride, No. 3 vulcanizing agent and No. 5 vulcanizing agent mixed in a weight ratio of 4:3:4:1.

[0062] The reinforcing agent is carbon black N990.

[0063] Wherein the auxiliary agent is palm wax.

[0064] A preparation method of a special fluororubber motor sealing ring for nuclear power, comprising the following steps:

[0065] (1) Premixing: Mix the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| deformation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com