A kind of method for preparing alkyd resin based on tmp rectification heavy raffinate as raw material

An alkyd resin, heavy-duty technology, applied in the field of fine chemicals, can solve problems such as unfavorable environmental protection and resource reuse, improvement, and unfavorable economic benefits, and achieve the effects of bright color, simple process and strong color retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

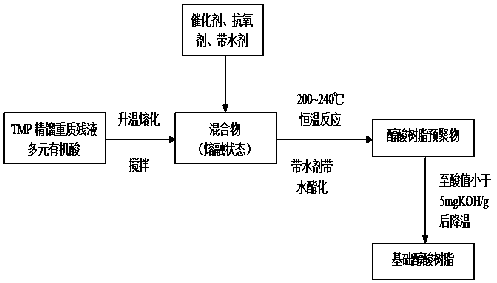

Method used

Image

Examples

Embodiment 1

[0027] The raw material TMP rectification heavy raffinate and phthalic anhydride are in accordance with the mass ratio of 2.75~2.85:1, the solid acid p-TSA with a mass fraction of 0.17%, the triphenyl phosphite with a mass fraction of 0.01%, and the triphenyl phosphite with a mass fraction of 3%. Xylene is added to the reactor equipped with agitator, thermometer, water separator (filled with xylene) and condenser, and the temperature is raised slowly. After the raw materials are melted, the stirring is started, and the constant temperature reaction is carried out after the temperature rises to 220°C. Take a sample for one hour to measure the acid value of the reaction system. Stop heating immediately when the acid value is less than 5mgKOH / g. After the temperature is lowered to about 100 degrees, add an organic solvent with a mass fraction of 20%, stir and mix evenly, and then discharge. Measure the viscosity, hydroxyl value, acid value, solid content, etc. of the reaction so...

Embodiment 2

[0033] The raw material TMP rectification heavy residue and phthalic anhydride, isophthalic acid according to the mass ratio of 3.6~3.7:1:1.5, the solid acid p-TSA with a mass fraction of 0.21%, and the triphenyl phosphite with a mass fraction of 0.01% Add xylene with a mass fraction of 3% into a reactor equipped with a stirrer, a thermometer, a water separator (filled with xylene) and a condenser, and slowly raise the temperature. After the raw materials are melted, start stirring, and wait until the temperature rises to 220°C Then carry out constant temperature reaction, and take samples every hour to measure the acid value of the reaction system. Stop heating immediately when the acid value is less than 5mgKOH / g. After the temperature is lowered to about 100 degrees, add an organic solvent with a mass fraction of 20%, stir and mix evenly, and then discharge. Measure the viscosity, hydroxyl value, acid value and solid content of the reaction solution.

[0034] Viscosity (s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com