Modified phenolic resin used for outdoor recombination bamboo production and preparation method thereof

A phenolic resin, modified technology, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesive types, adhesives, etc., can solve the problems of high bonding strength, pollution of the environment, poor impregnation and penetration, etc., to ensure bonding effect, increase the solid content, improve the effect of wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

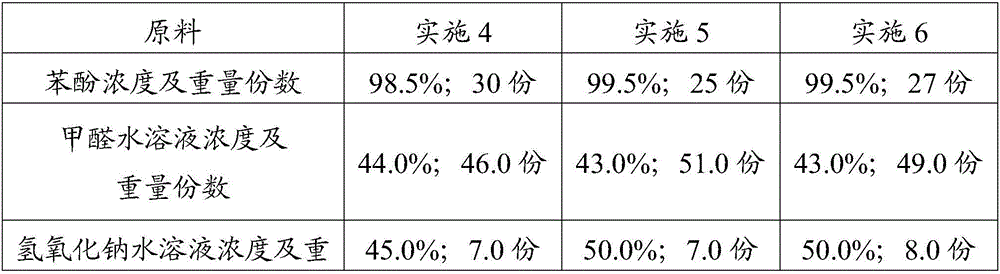

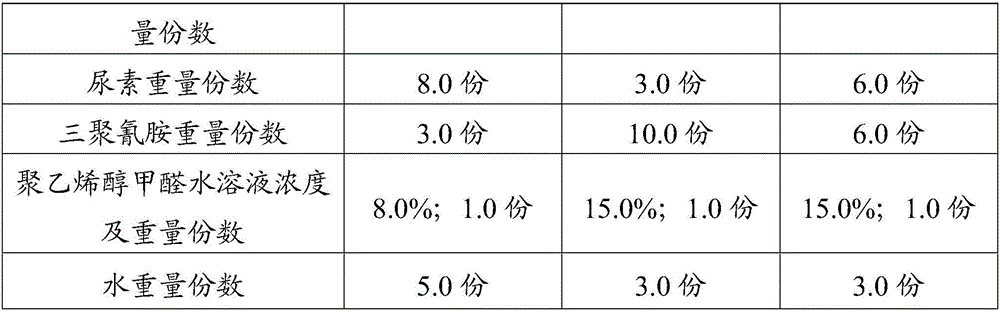

Examples

Embodiment 1

[0030] The present invention is used to produce a kind of embodiment of the modified phenolic resin of outdoor recombinant bamboo, the preparation method of the modified phenolic resin described in this embodiment is:

[0031] 1) First add formaldehyde aqueous solution I and alkaline aqueous solution I, start stirring and then add urea, heat up to 55°C and stir for 8 minutes;

[0032] 2) After the stirring is completed, add phenol I and alkaline aqueous solution II, and control the temperature at 65°C during the addition process; after the addition is completed, the exothermic reaction that starts causes the solution to heat up to 80°C;

[0033] 3) keep warm at 80°C until the viscosity value measured at 30°C reaches 70cps;

[0034] 4) Cool down immediately and add water. When the solution cools down to 70°C, add phenol II and alkaline aqueous solution III, and keep warm at 60°C for 110 minutes; immediately add melamine and phenol III, then add formaldehyde aqueous solution II ...

Embodiment 2

[0041] The present invention is used to produce another kind of embodiment of the modified phenolic resin of outdoor recombinant bamboo, the preparation method of the modified phenolic resin described in this embodiment is:

[0042] 1) First add formaldehyde aqueous solution I and alkaline aqueous solution I, start stirring, then add urea, heat up to 60°C and stir for 10 minutes;

[0043] 2) After the stirring is completed, add phenol I and alkaline aqueous solution II, and control the temperature at 60°C during the addition process; after the addition is completed, the exothermic reaction that starts causes the solution to heat up to 83°C;

[0044] 3) keep warm at 80°C until the viscosity value measured at 30°C reaches 76cps;

[0045] 4) Cool down immediately and add water. When the solution cools down to 70°C, add phenol II and alkaline aqueous solution III, and keep warm at 64°C for 118 minutes; immediately add melamine and phenol III, then add formaldehyde aqueous solution...

Embodiment 3

[0052] The present invention is used to produce another kind of embodiment of the modified phenolic resin of outdoor recombinant bamboo, the preparation method of the modified phenolic resin described in this embodiment is:

[0053] 1) First add formaldehyde aqueous solution I and alkaline aqueous solution I, start stirring, then add urea, heat up to 65°C and stir for 15 minutes;

[0054] 2) After the stirring is completed, add phenol I and alkaline aqueous solution II, and control the temperature at 50°C during the addition process; after the addition is completed, the exothermic reaction that starts causes the solution to heat up to 85°C;

[0055] 3) Insulate at 85°C until the viscosity value measured at 30°C reaches 80cps;

[0056] 4) Cool down immediately and add water. When the solution cools down to 70°C, add phenol II and alkaline aqueous solution III, and keep warm at 65°C for 130 minutes; immediately add melamine and phenol III, then add formaldehyde aqueous solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com