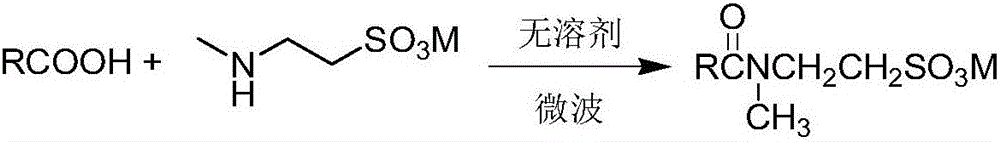

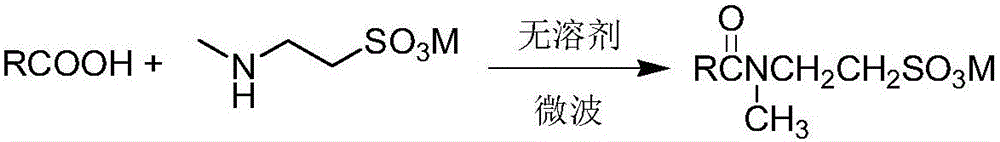

Method for synthesizing N-acyl-N-methyl taurine salt through microwave

A technology of methyl taurine and microwave synthesis, applied in the preparation of sulfonate, organic chemistry, etc., can solve the problems of large environmental pollution and high cost, and achieve the effects of good selectivity, short reaction time and little skin damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 2.1g (10.5mmol) of lauric acid and 1.61g (10mmol) of sodium N-methyl taurate, add them into a microwave tube, put them in a 600W microwave oven, and react at 100°C for 60min. After the reaction is completed, cool to 20 ℃, add 5mL of 95% ethanol to beat, filter with suction, wash with 3x3mL of 95% ethanol, and dry to obtain 3.46g of N-lauroyl-N-methyl taurine sodium, the yield is 95.8%, and the product purity is 99.1 %.

Embodiment 2

[0031] Weigh 3.43g (15mmol) of myristic acid and 1.78g (10mmol) of potassium N-methyl taurate, put them into a microwave tube, put them in a 600W microwave oven, and react at 200°C for 20min. After the reaction is completed, cool to 10°C , add 10mL of 95% ethanol to beat, filter with suction, wash with 3x5mL of 95% ethanol, and dry to obtain 3.81g of potassium N-myristoyl-N-methyl taurate, with a yield of 94% and a product purity of 99% .

Embodiment 3

[0033] Weigh 3.08g (12mmol) of palmitic acid and 1.56g (10mmol) of N-methylammonium taurate, put them into a microwave tube, put them in a 600W microwave oven, and react at 150°C for 35min. After the reaction is completed, cool to 0°C , add 10mL of 90% ethanol to beat, filter with suction, wash with 3x5mL of 90% ethanol, and dry to obtain 3.96g of potassium N-palmitoyl-N-methyl taurate, with a yield of 96% and a product purity of 99.2% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com