A special gelling powder for anti-acid and alkali heavy metal

A heavy metal, acid and alkali resistant technology, applied in the field of gelled powder, can solve the problems of not being found, the influence of the surrounding environment, etc., and achieve the effect of good durability and good water dispersion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

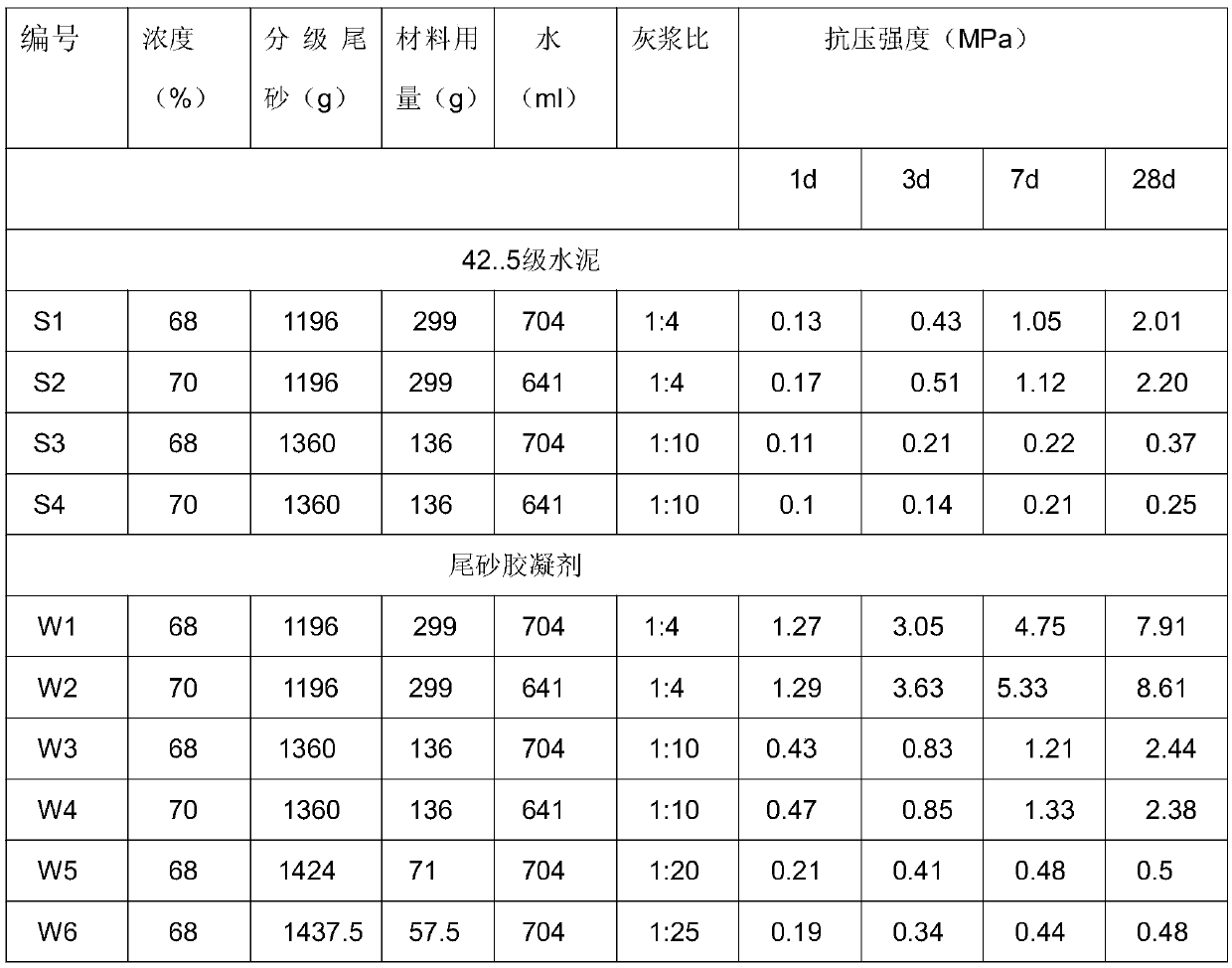

Examples

Embodiment 1

[0024] A special gelling powder for anti-acid and alkali heavy metals, which is prepared from the following raw materials in proportion by weight: 40 parts of steel slag, 30 parts of furnace slag, and 15 parts of calcium intensifying material, wherein the calcium intensifying material is waste ore and briquette The product after high-temperature calcination in the vertical kiln of automatic machine; Its preparation method comprises the following steps:

[0025] Step 1), weighing 40 parts of steel slag, 30 parts of slag, and 4.5 parts of calcium intensified material, mixing the weighed steel slag, slag, and calcium intensified material, and adding them to a mill for coarse grinding to obtain mixed particles; Weigh 10.5 parts of the calcium stimulating material, place it in a mill and grind it to obtain calcium stimulating material particles;

[0026] Step 2), placing the mixed particles prepared in step 1) in a furnace for high-temperature calcination, the calcination temperatu...

Embodiment 2

[0031] A special gelling powder for anti-acid and alkali heavy metals, which is prepared from the following raw materials in proportion by weight: 48 parts of steel slag, 35 parts of furnace slag, and 22 parts of calcium intensifying material, wherein the calcium intensifying material is waste ore and briquette The product after high-temperature calcination in the vertical kiln of automatic machine; Its preparation method comprises the following steps:

[0032] Step 1), weighing 40 parts of steel slag, 30 parts of slag, and 6.6 parts of calcium intensified material, mixing the weighed steel slag, slag, and calcium intensified material, and adding them to a mill for coarse grinding to obtain mixed particles; Weigh 15.4 parts of the calcium stimulating material, place it in a mill and grind it to obtain calcium stimulating material particles;

[0033] Step 2), placing the mixed particles prepared in step 1) in a furnace for high-temperature calcination, the calcination temperatu...

Embodiment 3

[0038] A special gelling powder for anti-acid and alkali heavy metals, which is prepared from the following raw materials in proportion by weight: 55 parts of steel slag, 40 parts of furnace slag, and 30 parts of calcium intensifying material, wherein the calcium intensifying material is waste ore and briquette The product after high-temperature calcination in the vertical kiln of automatic machine; Its preparation method comprises the following steps:

[0039] Step 1), weighing 40 parts of steel slag, 30 parts of slag, and 9 parts of calcium intensifying material, mixing the weighed steel slag, slag, and calcium intensifying material, and adding them to a mill for coarse grinding to obtain mixed particles; Weigh 21 parts of calcium stimulating material, place in a mill and grind to obtain calcium stimulating material particles;

[0040] Step 2), placing the mixed particles prepared in step 1) in a furnace for high-temperature calcination, the calcination temperature is contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com