Method for preparing micron-scale SnO square flakes

A micron-scale, square-shaped technology, applied in the direction of tin oxide, etc., can solve the problems of difficult cleaning and increase the production cost, and achieve the effect of uniform size, controllable shape and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of preparation method of micron SnO square plate material, this method is specifically: 4.5g stannous chloride dihydrate, 60mL water, 1.6g sodium hydroxide, 0.4g sodium chloride are placed in the beaker of 150mL, at room temperature The mixture was stirred at low temperature for 1 h, and then the obtained liquid was transferred to a hydrothermal reaction kettle, and reacted in an oven at 200° C. for 6 h. The product was centrifuged, washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 40°C for 6 hours to obtain a micron-sized SnO square sheet material.

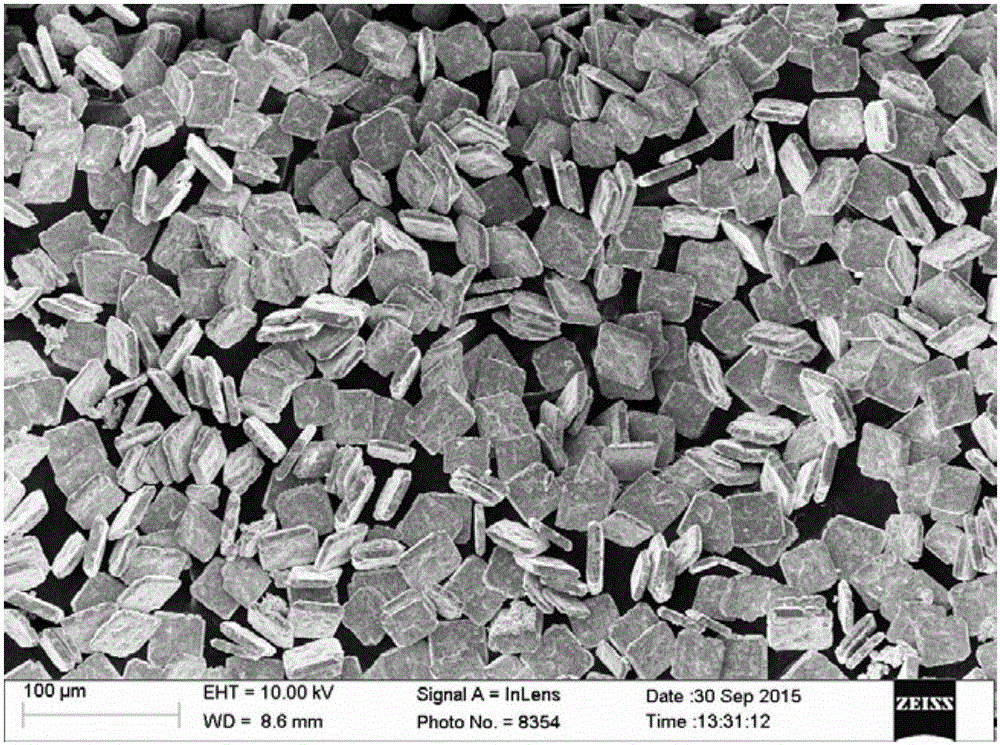

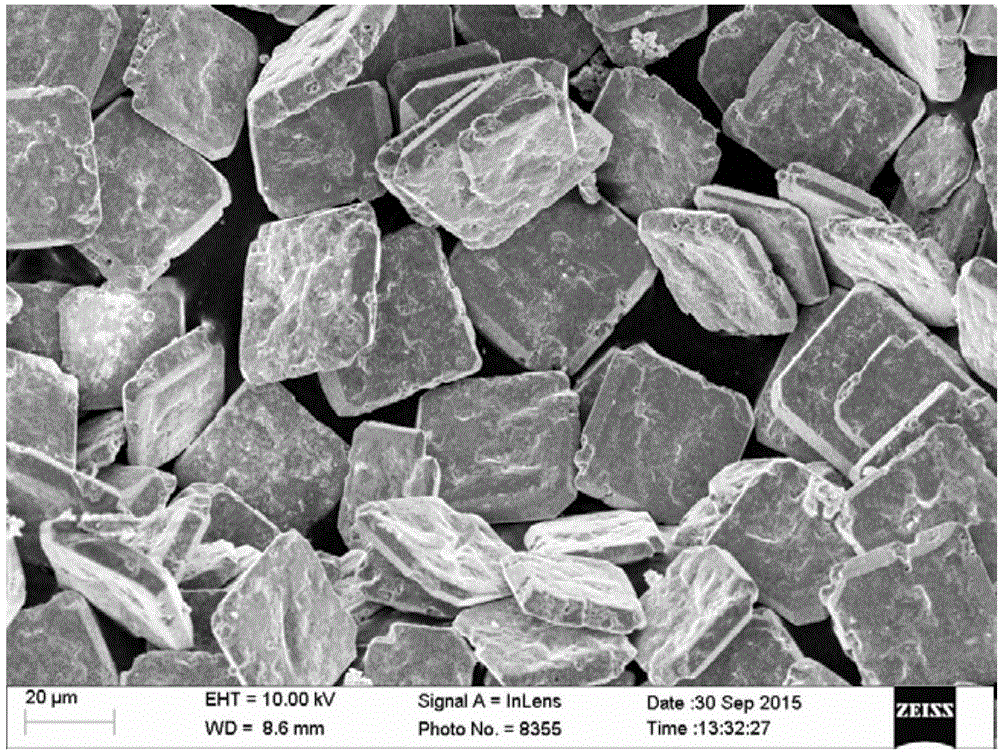

[0021] Figure 1(a) and Figure 1(b) are SEM images of micron-sized SnO square sheet materials. It can be seen from the figure that the prepared SnO has a square sheet structure with uniform size and regular shape.

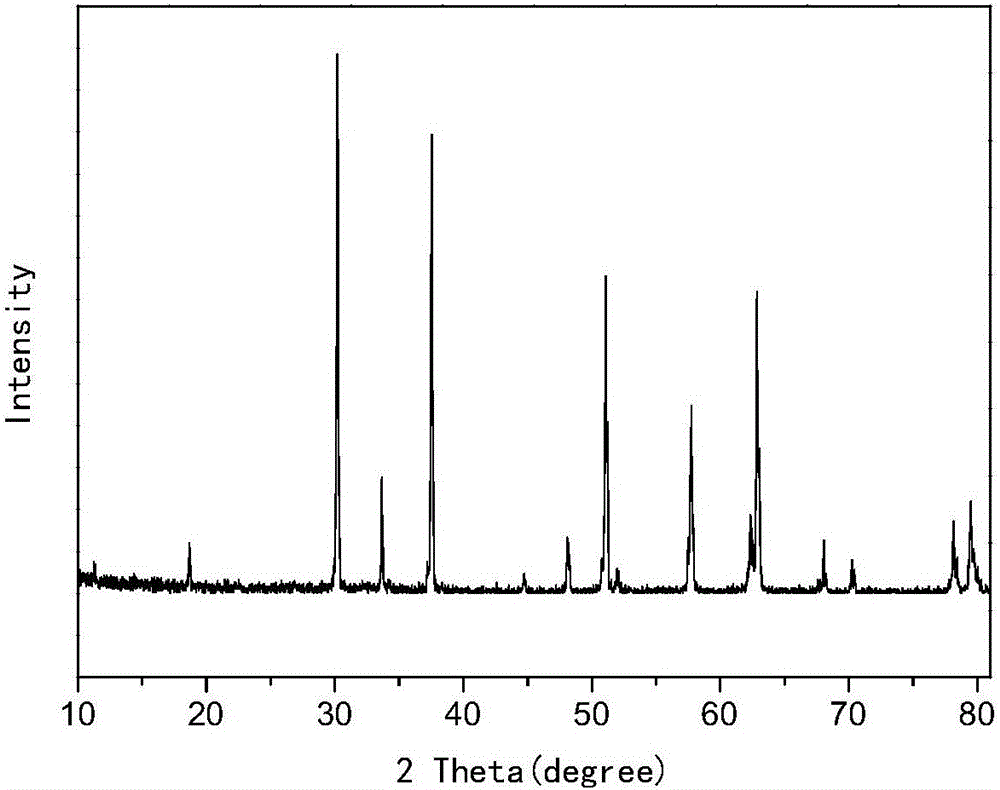

[0022] figure 2 It is the XRD picture of the micron-sized SnO square sheet material, and each peak position in the figure can correspond to the SnO standard pea...

Embodiment 2

[0024] A preparation method of a micron-scale SnO square sheet material, the method is specifically: 4g stannous chloride dihydrate, 80mL water, 1.42g sodium hydroxide, 0.5g sodium chloride are placed in a 150mL beaker, at room temperature After stirring for 1 h, the resulting liquid was transferred to a hydrothermal reactor, and reacted in an oven at 210° C. for 6 h. The product was centrifuged, washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 40°C for 6 hours to obtain a micron-sized SnO square sheet material.

Embodiment 3

[0026] A preparation method of a micron-scale SnO square sheet material, the method is specifically: 5g stannous chloride dihydrate, 70mL water, 1.8g sodium hydroxide, 0.7g sodium chloride are placed in a 150mL beaker, at room temperature After stirring for 1.5 h, the resulting liquid was transferred to a hydrothermal reactor, and reacted in an oven at 200° C. for 8 h. The product was centrifuged, washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 40°C for 6 hours to obtain a micron-sized SnO square sheet material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com