Automatic lifting safety rod for power transmission equipment iron tower

A technology for power transmission equipment and automatic lifting, which is applied in the direction of lifting equipment safety devices, lifting devices, etc., which can solve problems such as affecting the efficiency of cable construction, inability to climb towers, and cable laying effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

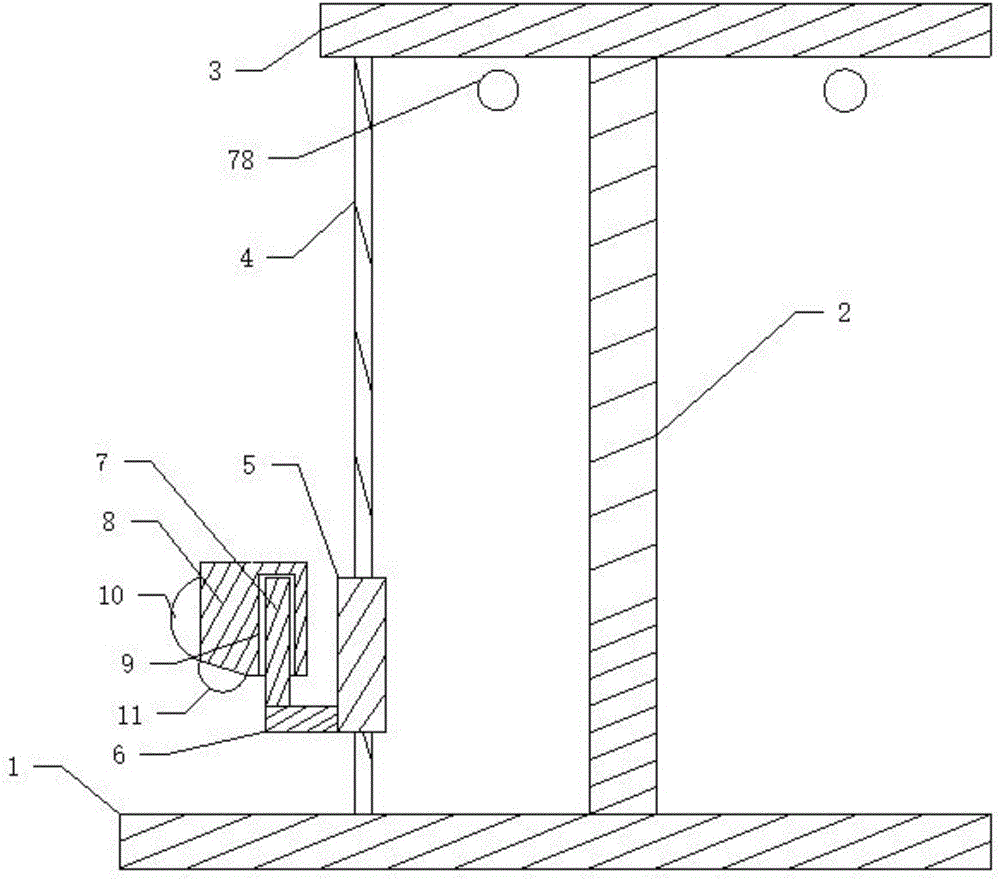

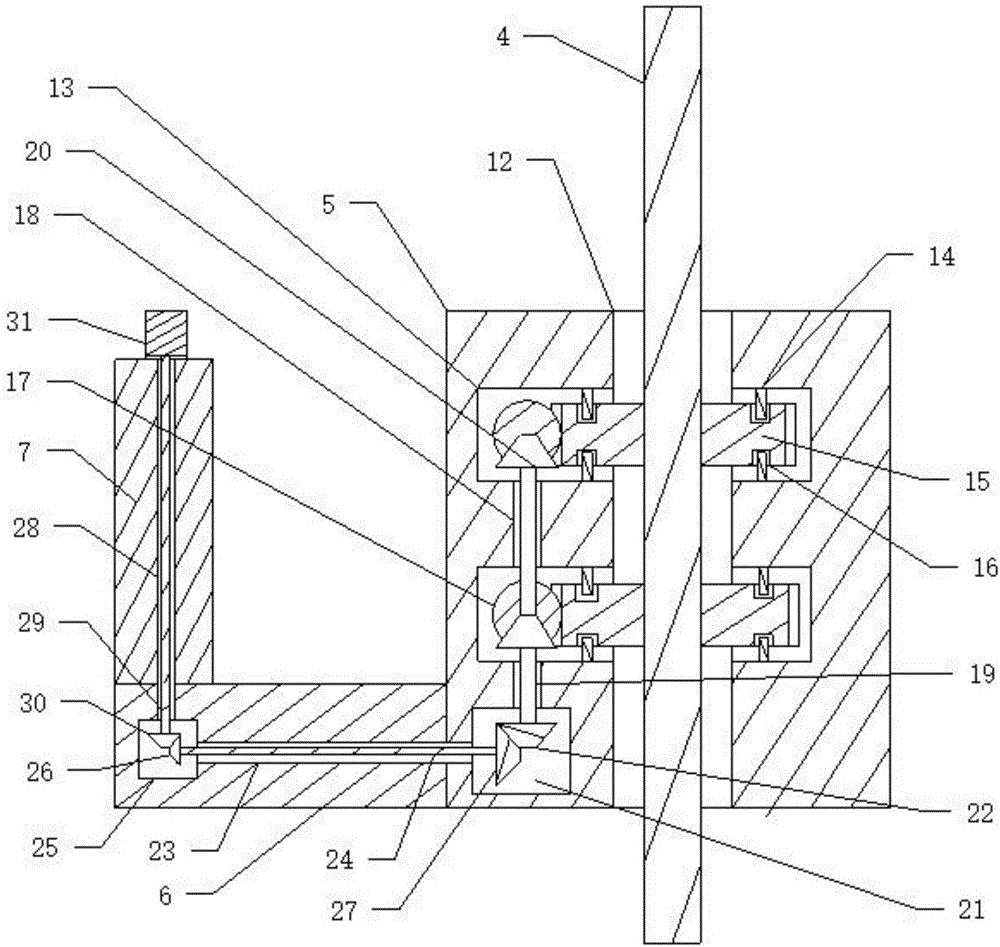

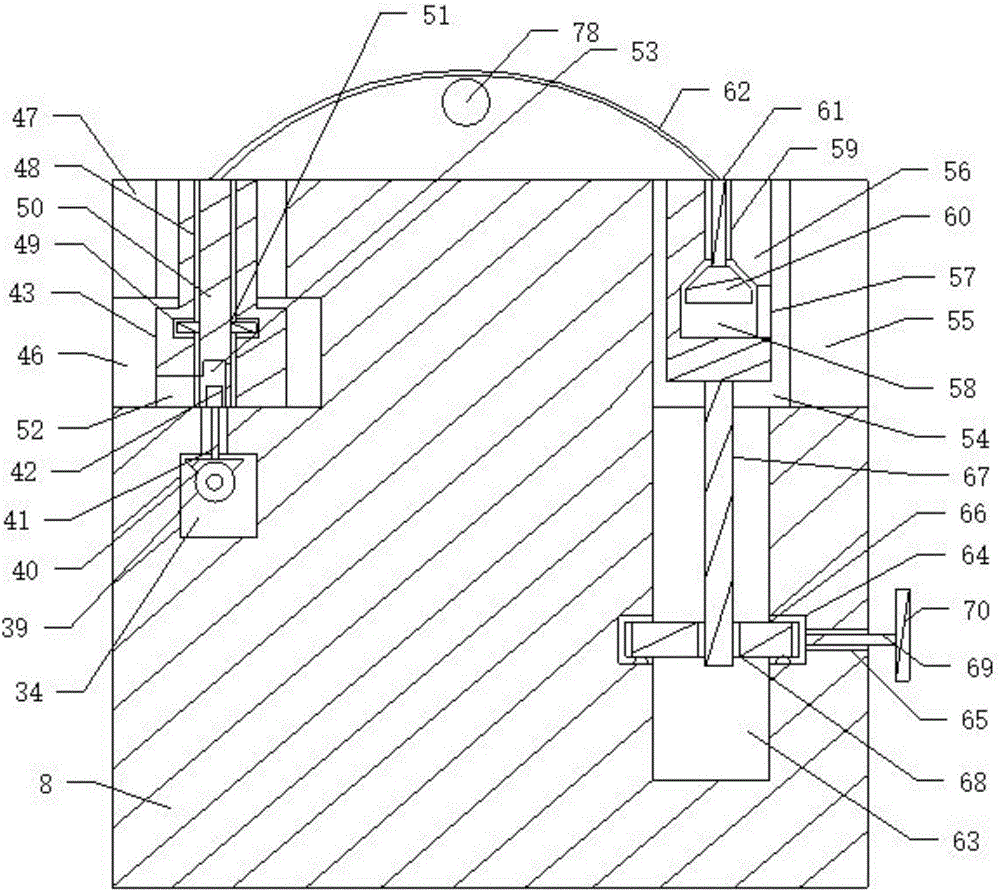

[0036] Such as Figure 1 to Figure 7 As shown, an electric power transmission equipment tower automatic lifting safety bar includes a fixed pier 1, a high-voltage iron tower 2 is provided on the fixed pier 1, and a cable support 3 is also provided on the high-voltage iron tower 2. The cable support 3 A high-voltage cable 78 is arranged on it, and a high-voltage iron tower 2 is arranged on the fixed pier 1. The fixed pier 1 is buried in the ground, and a cable support 3 is arranged on the high-voltage iron tower 2, so that the high-voltage wire can be The cable 78 is fixed on the stay wire support 3 .

[0037] A threaded rod 4 is connected to the stay wire support 3, and the threaded rod 4 is correspondingly connected to the fixed pier 1. A threaded rod 4 is connected to the stay wire support 3, and the threaded rod 4 is connected to the Fixed on 1, so as to be able to correspondingly connect the stay wire support 3 and the support of the fixed pier 1 through a threaded rod 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com