A system and method for automatically grabbing and placing drill pipes by a joint crane

A technology for drill pipes and cranes, which is applied in the field of automatic pick-and-place drill pipe systems for joint cranes, which can solve problems such as improved operating efficiency, incorrect alignment of drill pipes, and less time spent, so as to improve work efficiency, reduce capacity requirements, and judge way simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0046] A system for automatically grabbing and placing drill pipes by a joint crane, comprising a joint crane body and a grab rod control device, the output end of the grab rod control device is connected to the joint crane body;

[0047] Such as figure 1 As shown, the articulated crane body includes a main body swing 1, a main arm 2, an auxiliary arm 3 and a clamper 4; one end of the main arm 2 is hinged on the main body swing 1, and the other end of the main arm 2 is connected to the auxiliary arm 2. The front end of the arm 3 is hinged; the end of the auxiliary arm 3 is provided with a clamper 4 capable of rotating along the central axis of the auxiliary arm 3;

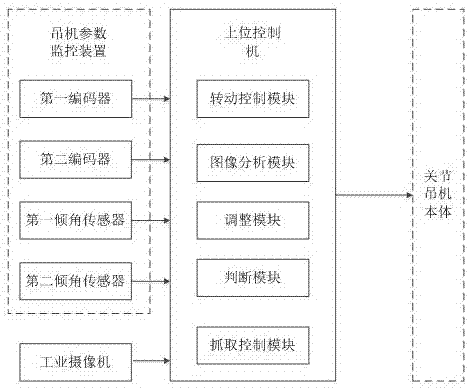

[0048] Such as figure 2As shown, the grab bar control device includes an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com