Granulation device of water soluble initiating agent

A technology of water-soluble initiator and granulation device, which is applied in the direction of mold extrusion granulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

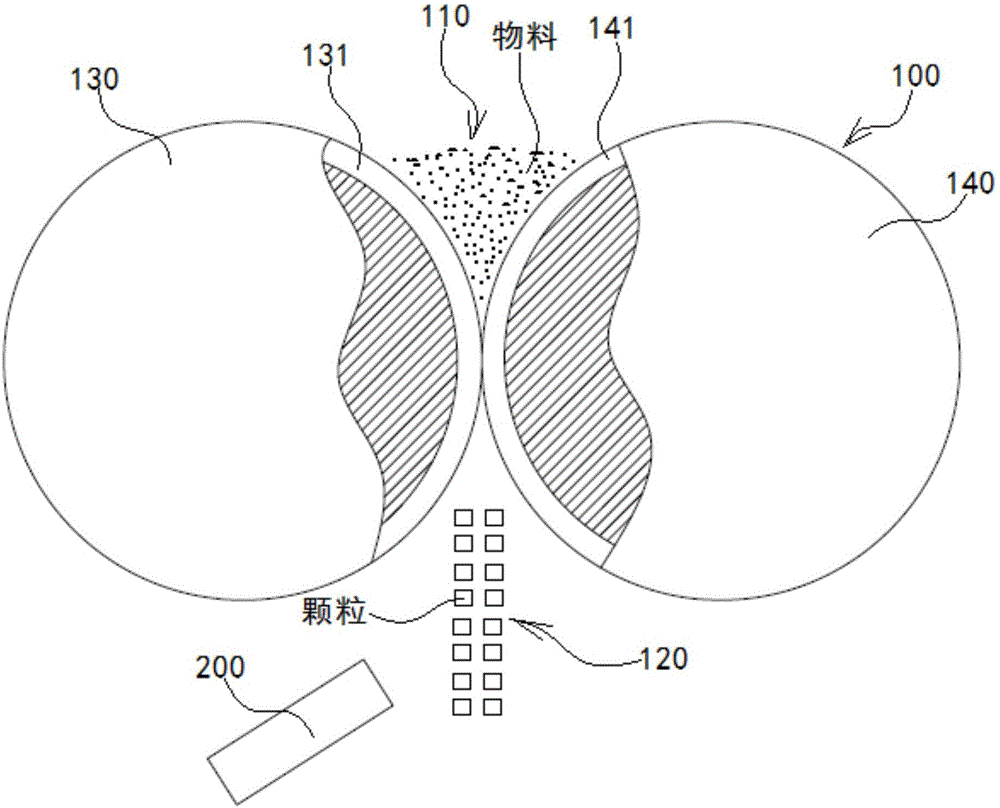

[0014] see figure 1 , the granulation device of a kind of water-soluble initiator that provides in the figure, comprises rolling type granulator 100, and this rolling type granulator 100 comprises a feed end 110 and a discharge end 120 and a pair of rollers 130, 140, the roll surface of each roll 130, 140 is provided with a number of corresponding semicircular grooves 131, 141 at intervals, the curved surface of the semicircular grooves 131, 141 is 1.5mm high, and the surface roughness is Ra0.16~0.32μm; in addition Below the pair of rollers 130, 140, a temperature probe 200 is arranged to detect the discharge temperature of the material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com