Flue gas purifying filter material for semi-dry desulphurization and preparation method thereof

A semi-dry desulfurization and flue gas purification technology, applied in chemical instruments and methods, separation methods, climate change adaptation, etc., can solve the problems of low filtration efficiency, poor corrosion resistance, dust paste bags, etc., and achieve oxidation resistance Excellent, strong corrosion resistance, filtration precision, waterproof and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

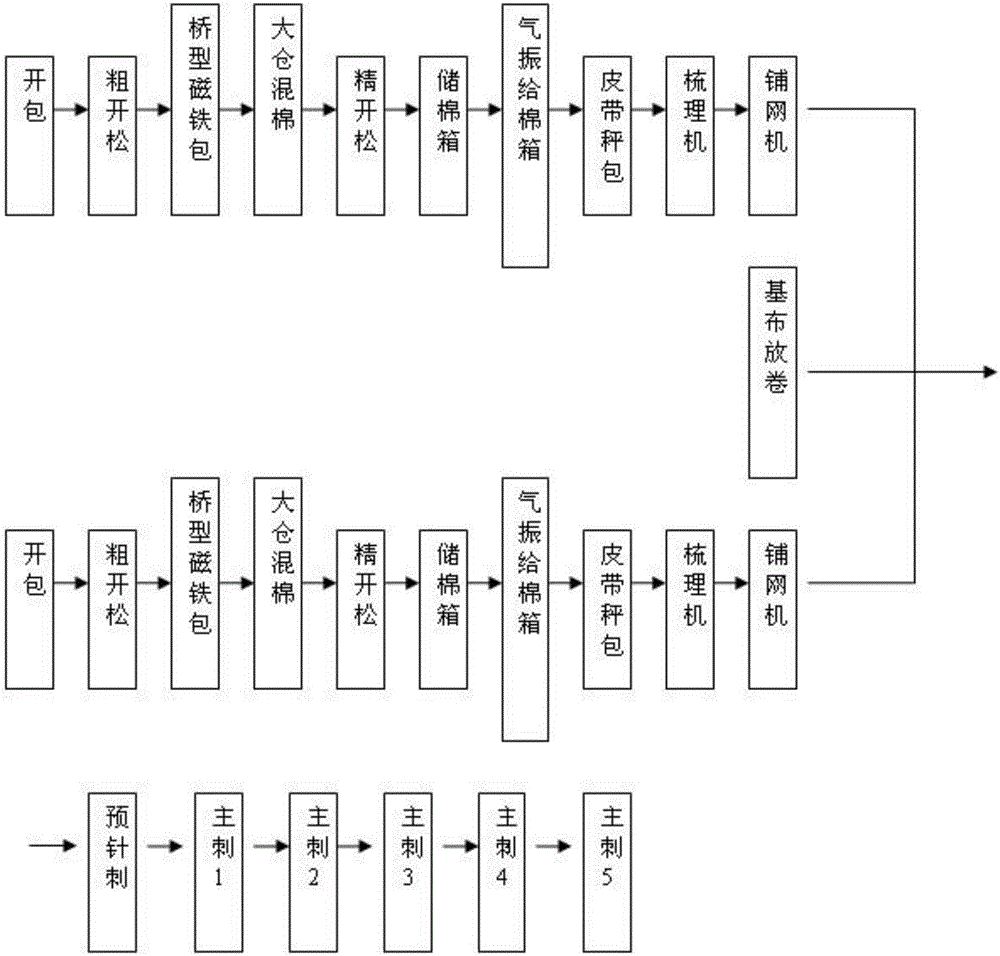

[0034] 1) Selection and preparation of raw materials

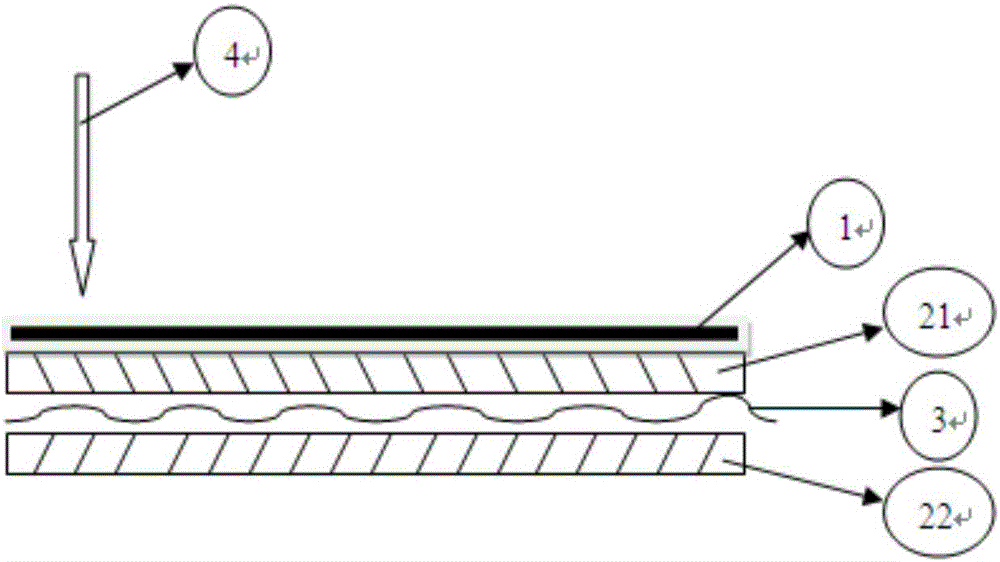

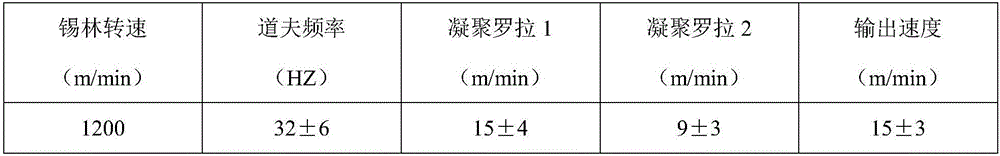

[0035] The polyimide fiber with a specification of 1.5D*60mm (fineness*length), the polytetrafluoroethylene fiber with a specification of 1.5dtex-5.5dtex*48mm (fineness*length) and the specification of 5.5μm*51mm (fineness*length) length) of acid-resistant glass fiber is uniformly mixed as a blended composite dust face layer fiber; the specification of polyimide fiber with a specification of 2.0D*60mm (fineness*length) is 3.5dtex-7.5dtex*48mm ( Fineness*length) polytetrafluoroethylene fiber and acid-resistant glass fiber with a specification of 5.5μm*51mm (fineness*length) are uniformly mixed as a blended composite clean air surface layer fiber for later use.

[0036] Fiber formula ①: 30% polyimide fiber + 30% polytetrafluoroethylene fiber + 40% acid-resistant glass fiber (the proportion of blended composite dust-facing surface fiber and blended composite air-cleaning surface layer fiber is the same, and the formula ① is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com