Non-oil-fried instant hollow noodles and preparation method thereof

An instant noodle, non-fried technology, applied in the direction of food science, food ingredients as a taste improver, and the function of food ingredients, etc., can solve the problems of insufficient nutrition, shortened brewing time, insufficient crude fiber, etc., to achieve shortened brewing time, improve processing performance, and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

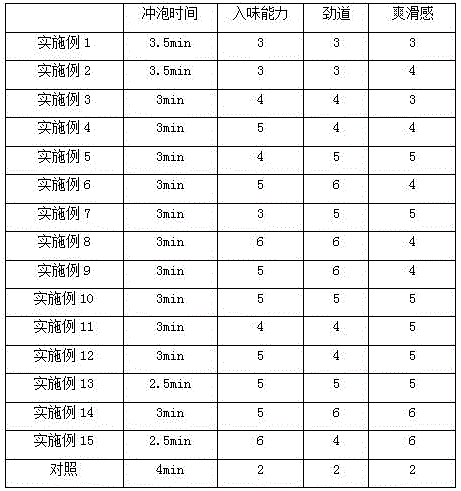

Examples

Embodiment 1

[0042] A non-fried hollow instant noodle, comprising the following raw materials in parts by weight: 60 parts of a mixture of highland barley flour and buckwheat flour, 5 parts of sweet potato flour, the highland barley flour and the buckwheat flour are compound enzyme modified Highland barley flour and buckwheat flour. The complex enzyme includes xylanase, protease, pentosanase, lipolytic enzyme, phytase, glucose oxidase, etc., and two or more of them can be selected.

Embodiment 2

[0044] A non-fried hollow instant noodle, comprising the following raw materials in parts by weight: 85 parts of a mixture of highland barley flour and buckwheat flour, 12 parts of sweet potato flour, the highland barley flour and the buckwheat flour are compound enzyme modified Highland barley flour and buckwheat flour; compound enzyme is a mixture of glucose oxidase, xylanase, protease and phytase.

Embodiment 3

[0046] A non-fried hollow instant noodle, comprising the following raw materials in parts by weight: 70 parts of a mixture of highland barley flour and buckwheat flour, 8 parts of sweet potato flour, the highland barley flour and the buckwheat flour are compound enzyme modified Highland barley flour and buckwheat flour; compound enzyme is a mixture of glucose oxidase, xylanase, protease and phytase.

[0047] The composite enzyme of this embodiment is prepared by the following method: dry 39% highland barley flour, 25% buckwheat flour, 4% glucose oxidase, 3% xylanase, 0.8% protease, 2% phytase, 25% Water and 1.2% salt, after stirring evenly, adjust the pH value to 6.5, at 30°C, after 36 hours of enzymatic hydrolysis, remove the enzyme solution, and dry it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com