An adjustable integral flat-plate quartz lamp heater structure

A quartz lamp and flat-plate technology, applied in the direction of ohmic resistance heating, ohmic resistance heating device, electric heating device, etc., can solve the problems of complicated test operation process, lamp tube bursting when heated, overflow of phase change medium, etc., and achieve simplified test operation Process, strong versatility and convenience, and the effect of meeting the test conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

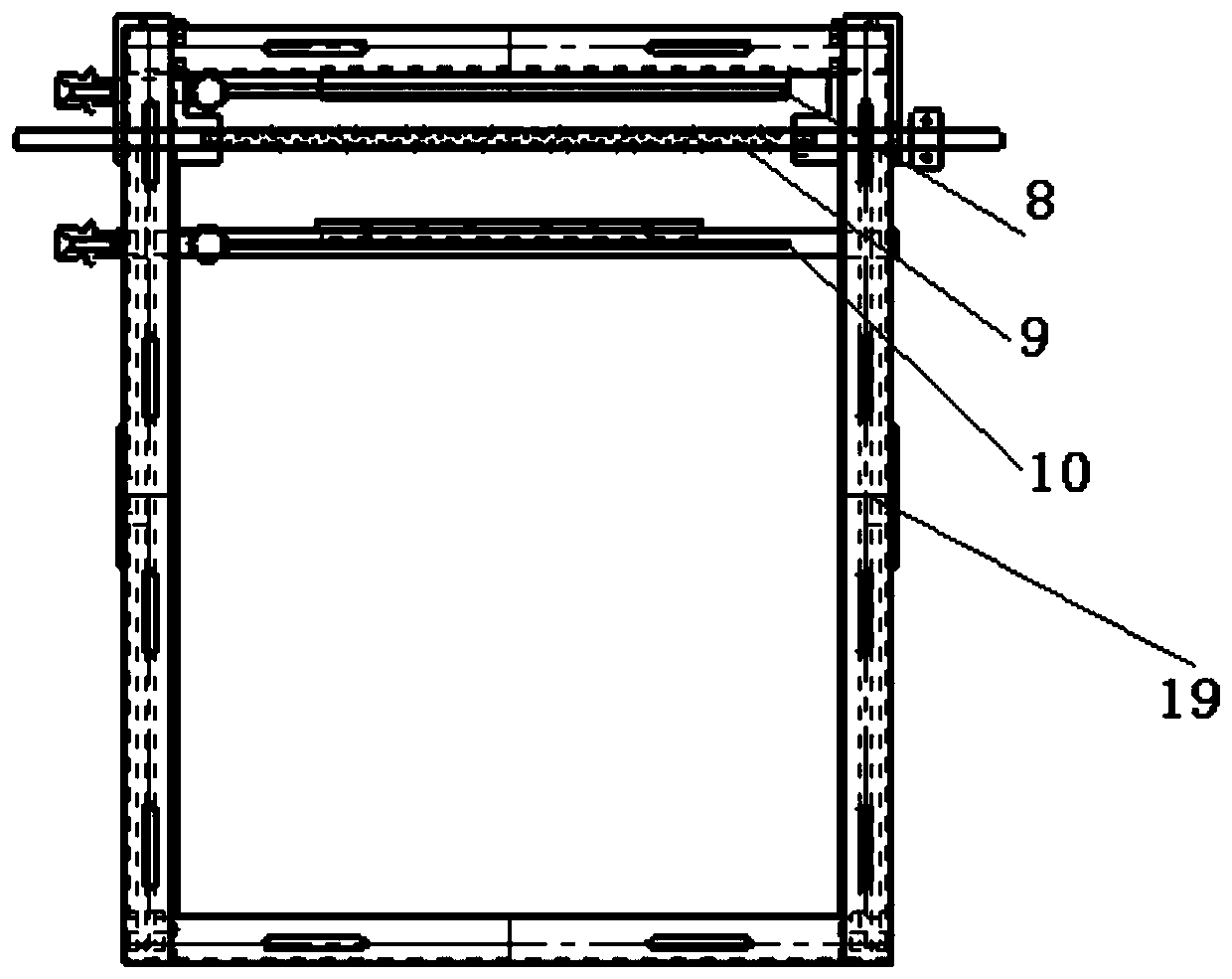

[0034] figure 1 It is a structural schematic diagram of the adjustable integral flat-plate quartz lamp heater structure of the present invention. Such as figure 1 As shown, the adjustable integral flat-type quartz lamp heater structure includes: trolley 1, bearing 2, flat-type quartz lamp heating assembly, rotatable frame 4 and handwheel brake disc locking device 5; wherein,

[0035] The bearing 2 includes a bearing seat 210 and a bearing support 211, the bearing seat 210 is connected to the bearing support 211; the bearing support 211 is arranged on the trolley 1, and the rotatable frame 4 is connected to the bearing seat 210 through a shaft; the flat quartz lamp heating assembly is arranged on The rotatable frame 4 ; the handwheel brake disc locking device 5 is connected with the bearing seat 210 .

[0036] Specifically, the bottom of the trolley 1 is a mobile pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com