Parameter extraction method for integrated gate commutated thyristor drive turn-off circuit and continuing current circuit

A commutating thyristor and shut-off circuit technology, which is applied in the fields of electrical digital data processing, CAD circuit design, special data processing applications, etc., can solve problems such as the freewheeling circuit operating conditions of the IGCT gate drive shut-off circuit that are not involved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

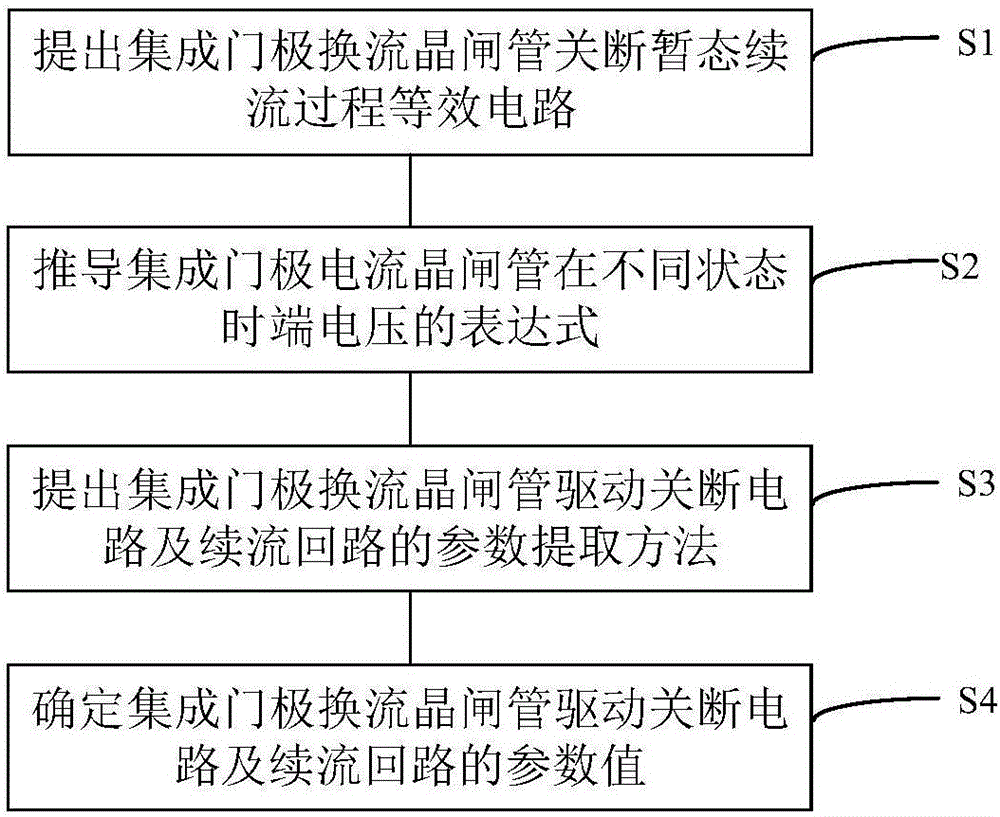

[0047] figure 1 It is a flowchart of the parameter extraction method of the present invention. Depend on figure 1 It can be seen that the present invention includes the following steps: Step 1: analyzing the operating characteristics of the integrated gate commutated thyristor drive circuit and the freewheeling circuit, and proposing an equivalent circuit for the transient freewheeling process of the integrated gate commutated thyristor; Step 2: according to the steps 1 The obtained equivalent circuit deduces the expression of the terminal voltage of the integrated gate current thyristor in different states; Step 3: Carry out the single-tube test experiment of the integrated gate commutated thyristor with a specific clamping voltage and turn-off current, and use the integrated gate Integrating the experimental results of the gate commutation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com