Verification method for attitude parameters of toptig welding torch in multi-layer welding of thick-walled pipe butt joints

A technology of butt joints and attitude parameters, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of affecting welding quality, high cost, and low efficiency, so as to improve design efficiency, eliminate cumbersome steps, reduce The effect of defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the embodiments.

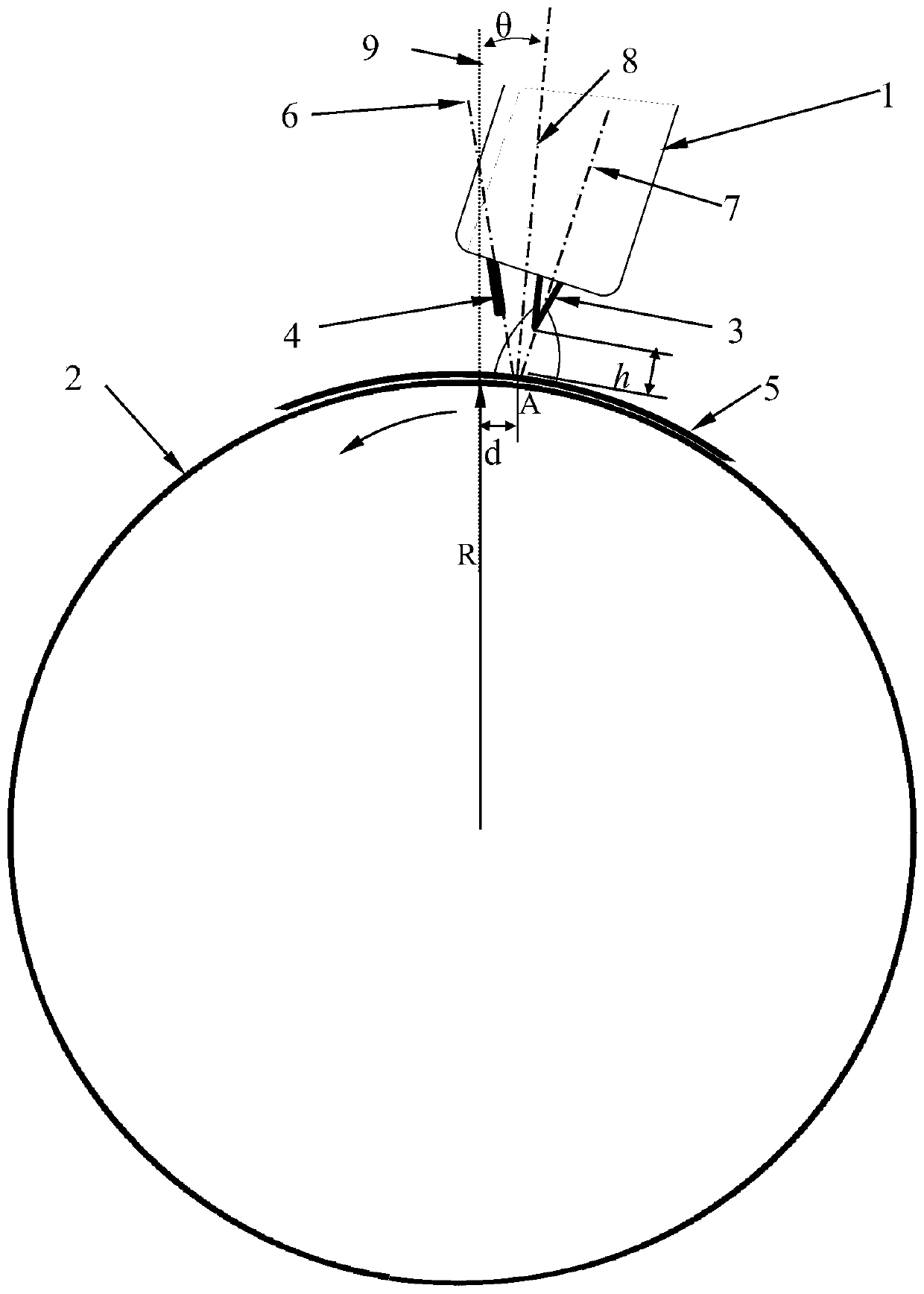

[0038] When using the TOPTIG welding gun attitude parameter verification method for multi-layer welding of thick-walled pipe butt joints of the present invention, the bottom radius of the groove of the thick-walled pipe to be welded is R=49mm, and the welding gun model used is TOPTIG180. The welding wire of this welding gun The inclination angle β=20°.

[0039] First, when the first layer is welded by bottom welding, the welding current I=140A, the shielding gas flow rate S=8L / min, the welding gun height h=4mm, and k=1.02 according to step 1.

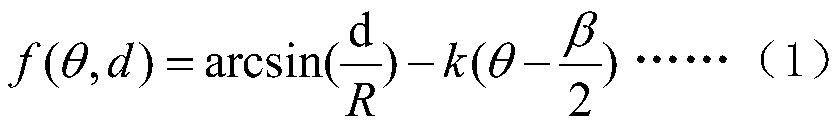

[0040] For the first layer of bottom welding bead, under the premise of ensuring that the welding torch attitude can actually reach the weld, the given welding torch attitude angle θ=0°, the welding torch offset distance d=-10mm, the above parameters are substituted into the welding torch attitude function In the expression (1),

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com