Online automatic cleaning device for thermal power plant air pre-heater

An air preheater and automatic cleaning technology, applied in lighting and heating equipment, flushing, cleaning heat transfer devices, etc., can solve problems such as incomplete cleaning, corrosion, and power plant operation obstacles, so as to improve cleaning effect and cleaning efficiency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

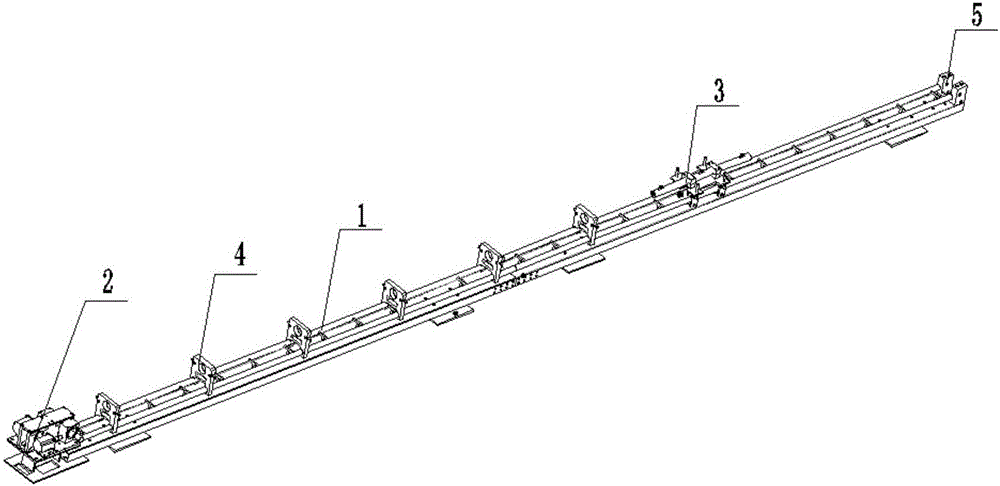

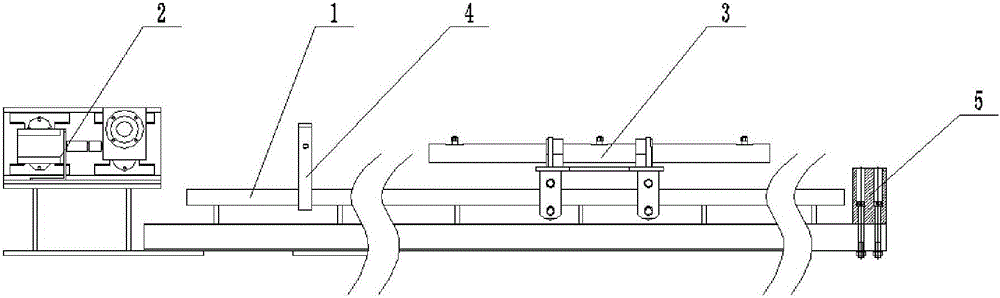

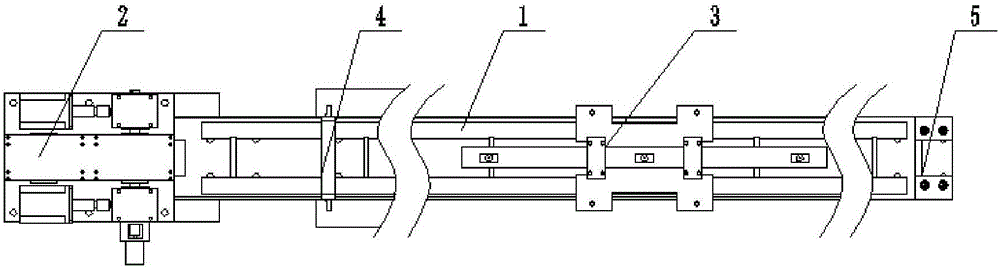

[0030] Such as Figure 1 to Figure 10 As shown, the present invention is an online automatic cleaning equipment for the air preheater of a thermal power plant, comprising a track 1, a tube twister 2 and a high-pressure water trolley 3, the tube twister 2 is arranged at one end of the track 1, and the high-pressure The water trolley 3 is arranged on the track 1; on the track 1, a number of high-pressure rubber hose support blocks 4 are arranged at intervals between the hose twister 2 and the high-pressure water trolley 3; Block 5; the high-pressure water trolley 3 includes a vehicle frame 6, a nozzle body steel pipe 7 and a wheel assembly, the nozzle body steel pipe 7 is fixed on the vehicle frame 6 through a pipe clamp 8, and several nozzles 9 are arranged on the nozzle body steel pipe 7 The wheel assembly is arranged below the vehicle frame 6; the tube twister 2 includes a frame 10, an active transmission shaft 11, a driven transmission shaft 12, a servo motor 13 and a reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com