Vertical flame channel and hot bed-connected type powder material continuous melting furnace

A technology of flame channel and melting furnace, which is applied in the field of melting furnace, can solve the problems of high operating cost, bulky volume, complicated operation, etc., achieve the effect of thorough cooling, increase the time of uniform mixing, and speed up the outflow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

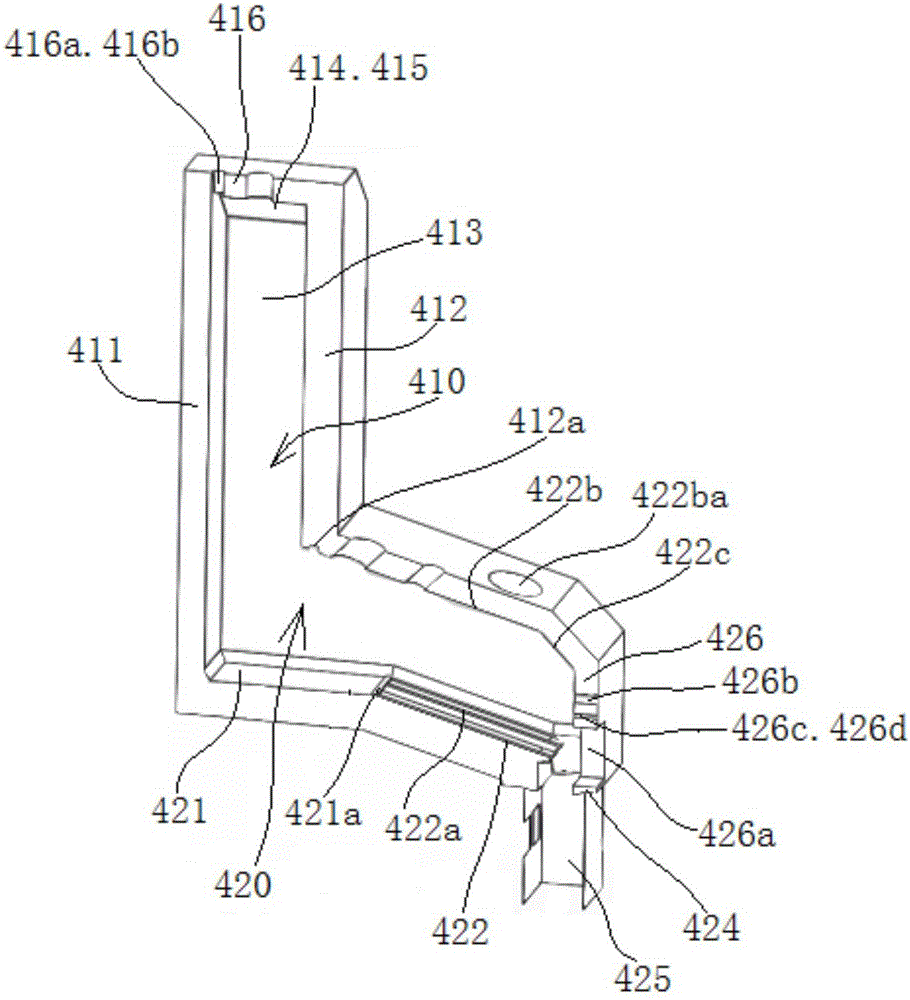

[0041] see Figure 1 to Figure 4 , the vertical flame channel shown in the figure is connected to the continuous melting furnace for hot bed powder materials, including a steel shell 100, the bottom of the steel shell 100 is provided with supporting feet 110, and a weighing bin 200 is installed on the top of the steel shell 100 A horizontal screw type quantitative feeder 210 is installed at the discharge port of the weighing bin 200, and a water-sealed slag remover 300 is installed at the bottom of the steel shell 100.

[0042] A continuous melting furnace 400 is arranged inside the steel shell 100 , and a refractory layer 500 and an insulating layer 600 are sequentially arranged between the outer surface of the continuous melting furnace 400 and the inner surface of the steel shell 100 .

[0043] The continuous melting furnace 400 is provided with a vertical flame channel 410 and a heat bed 420. The vertical flame channel 410 is surrounded by a front wall 411, a rear wall 412...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com