Double-compression three-way copper tube and forming method thereof

A tee, copper tube technology, applied in the direction of pipes, branch lines, pipes/pipe joints/pipes, etc., can solve the problems of high welding process requirements, high cost, high defect rate, and reduce product defect rate, reduce The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

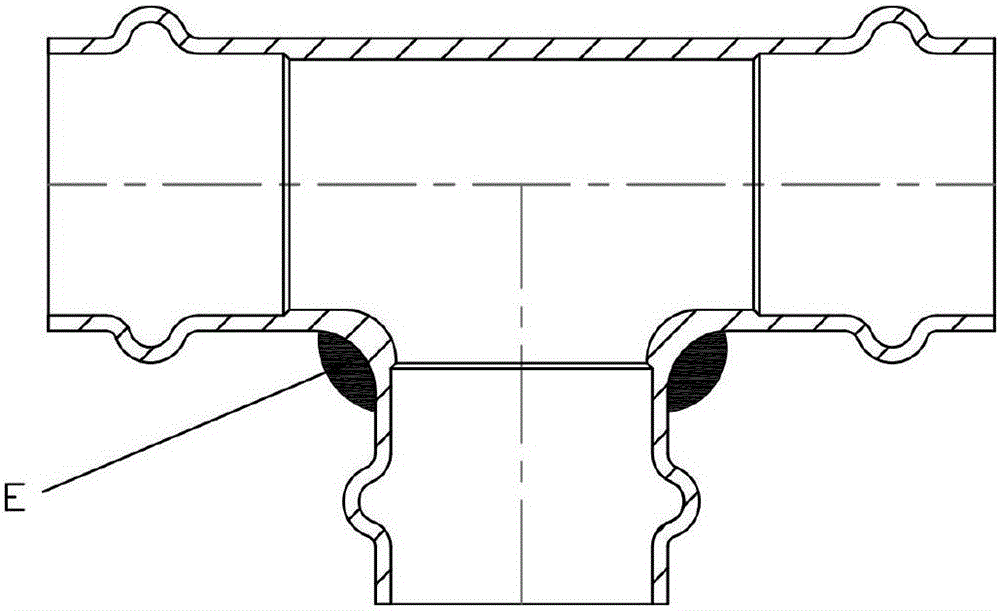

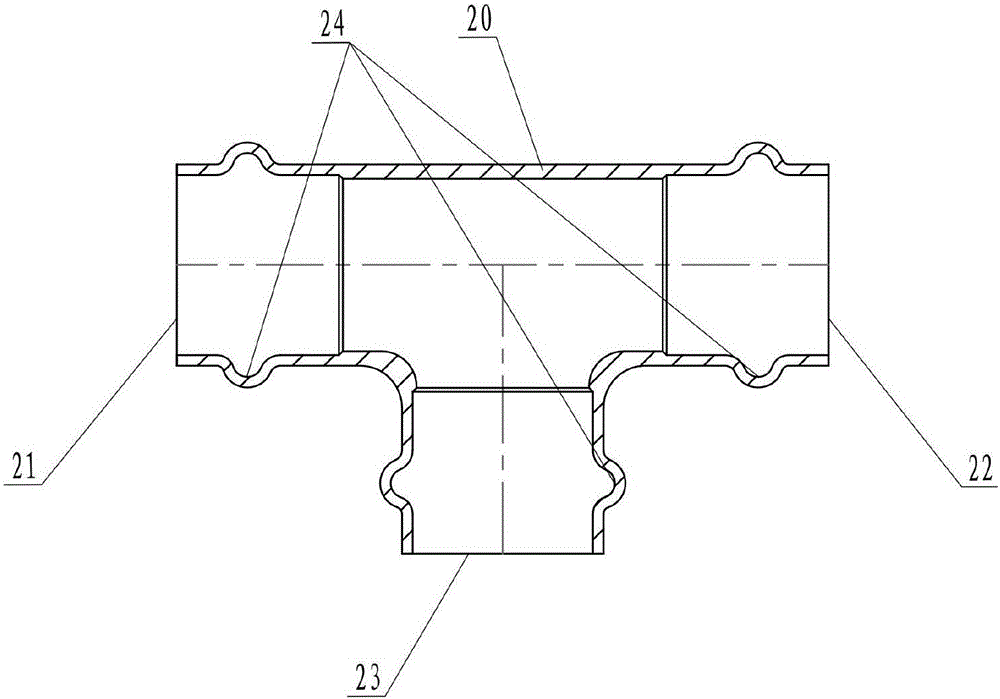

[0022] Such as figure 2 Shown is the double clamping three-way copper pipe of the present invention, the three-way main body 20, the main body 20 is provided with the first interface 21, the second interface 22, the third interface 23, the first interface 21, the second interface 22, the third interface The inner wall of the interface 23 is provided with an annular groove 24, and the inner diameters of the first interface 21, the second interface 22, and the third interface 23 are respectively larger than the inner diameter of the main body 20, and the first interface 21, the second interface 22, and the third interface 23 are connected to the main body. 20 have no welds.

[0023] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 Shown, the forming method step of the present invention's double clamping tee copper pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com