A polymer-coated nano-magnesium-based hydrogen storage material and preparation method thereof

A technology for hydrogen storage materials and polymers, used in transportation, packaging, metal processing equipment, etc., can solve the problem of high hydrogen absorption and desorption temperature, achieve excellent low temperature hydrogen absorption and desorption performance, ease volume shrinkage, and reduce grain boundary migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

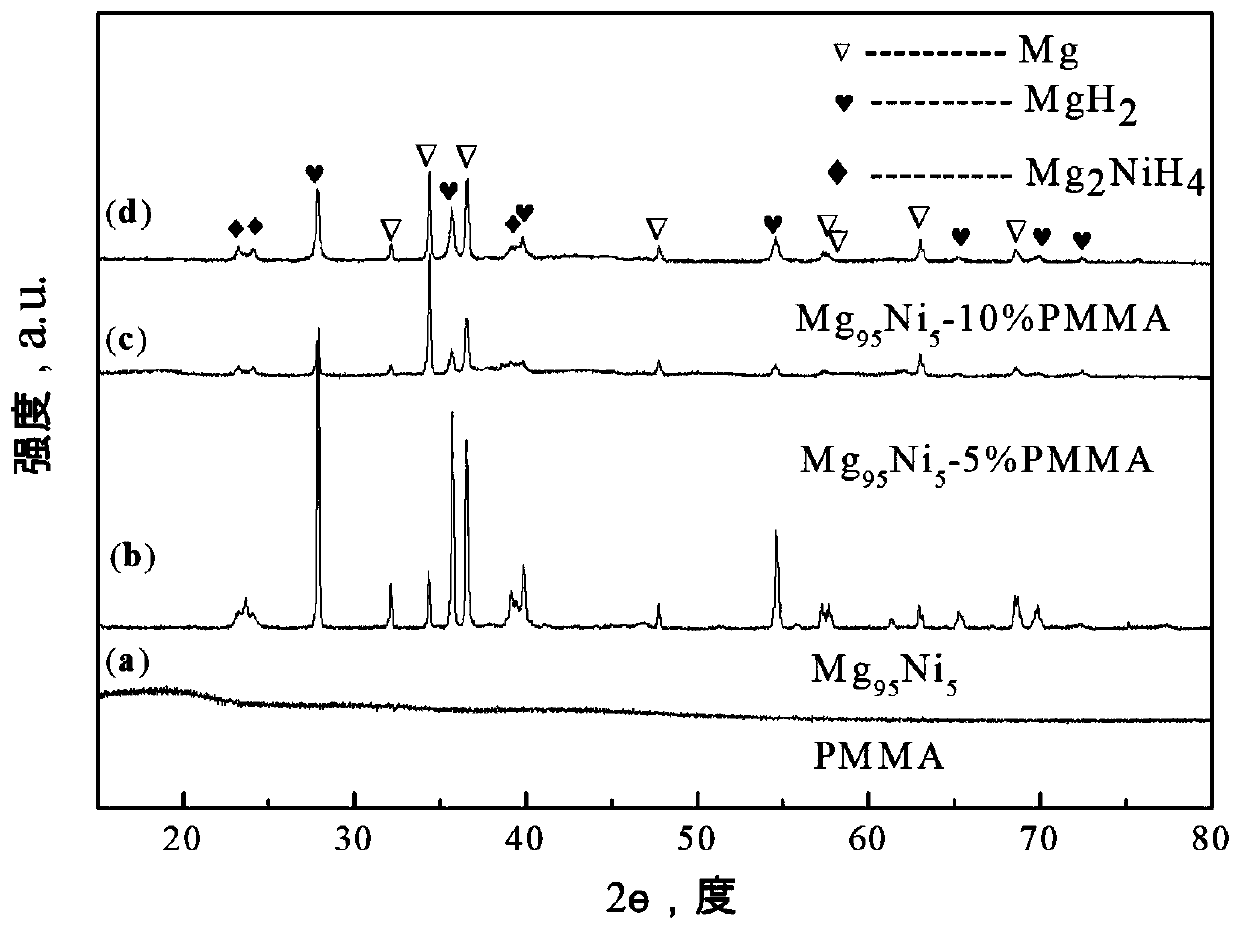

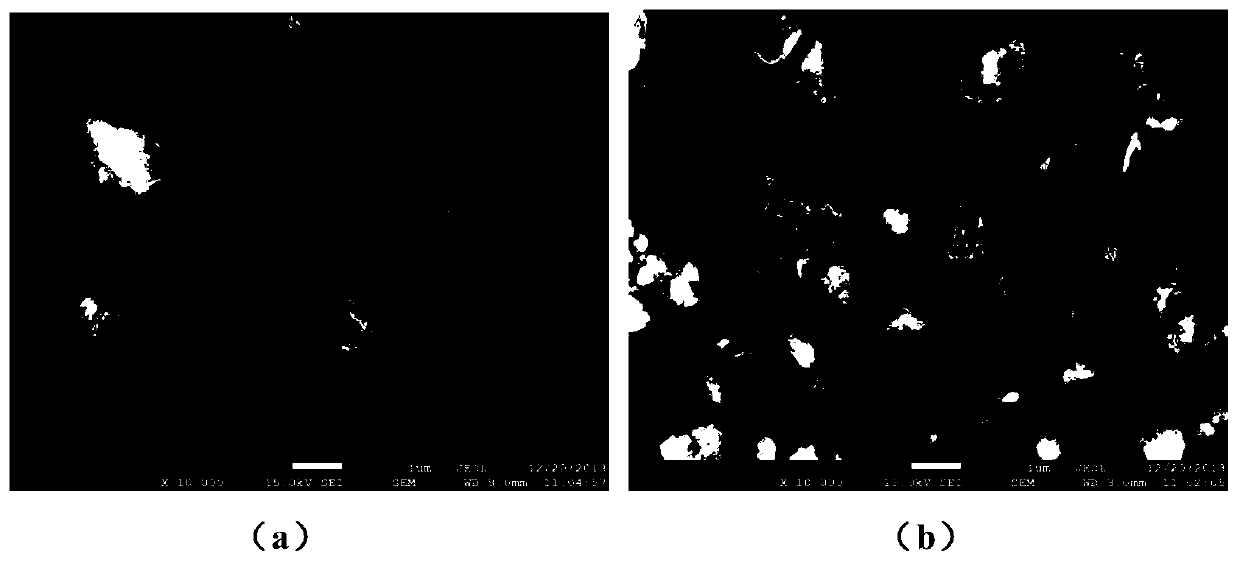

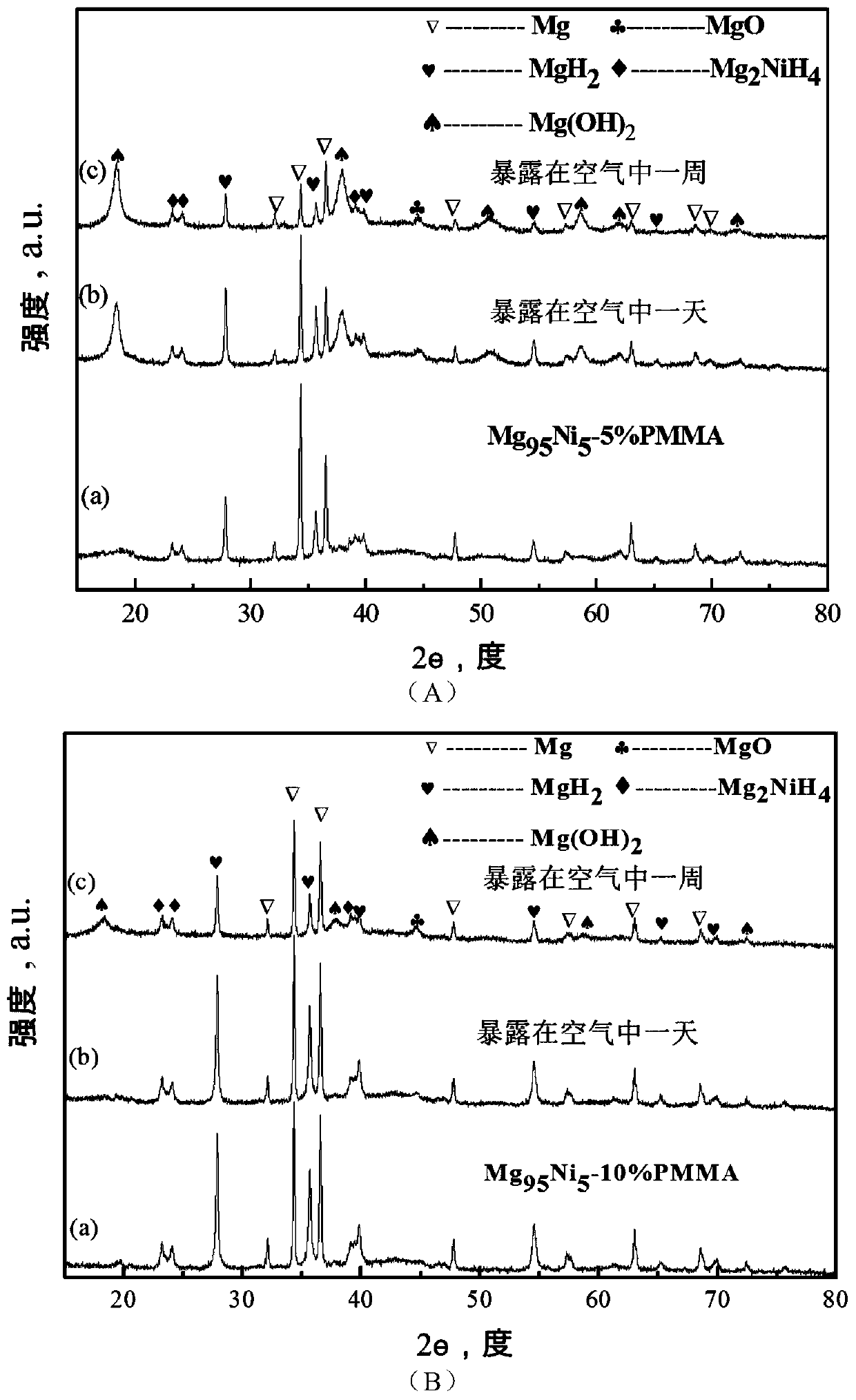

[0042] Example 1 Mg 95 Ni 5 Preparation of -5%PMMA nano-magnesium-based hydrogen storage material

[0043] (1) Put 9.5g of magnesium powder and 0.5g of nickel powder into a beaker for mixing pretreatment, add 40mL of acetone as a dispersant, use ultrasonic mixing for 1h, ultrasonic power is 1kW, and then dry at 80°C for 8h , to obtain magnesium-nickel mixed powder;

[0044] (2) The magnesium-nickel mixed powder is synthesized by hydrogenation combustion method. During the synthesis process, the magnesium-nickel mixed powder is heated to 580°C for 2h in a 2MPa hydrogen atmosphere, then cooled to 340°C for 4h, and finally cooled to room temperature to obtain a powder shaped magnesium-nickel alloy.

[0045] (3) Get 0.1g PMMA and put it into a beaker, add 20mL tetrahydrofuran, stir for 1h, be mixed with a polymer solution, get 1.9g of the powdered magnesium-nickel alloy obtained in step (2) and put it into a ball mill jar, and put the configured high Put the molecular solution...

Embodiment 2

[0049] Example 2 Mg 95 Ni 5 Preparation of -10%PMMA nano-magnesium-based hydrogen storage material

[0050] (1) Put 9.5g of magnesium powder and 0.5g of nickel powder into a beaker for mixing pretreatment, add 40mL of acetone as a dispersant, use ultrasonic mixing for 1h, ultrasonic power is 1kW, and then dry at 80°C for 8h, Obtain magnesium-nickel mixed powder;

[0051] (2) The magnesium-nickel mixed powder is synthesized by hydrogenation combustion method. During the synthesis process, the magnesium-nickel mixed powder is heated to 580°C for 2h in a 2MPa hydrogen atmosphere, then cooled to 340°C for 4h, and finally cooled to room temperature to obtain a powder shaped magnesium-nickel alloy.

[0052] (3) Get 0.2g PMMA and put it into a beaker, add 20mL tetrahydrofuran, stir for 1h, be mixed with a polymer solution, get 1.8g of the powdered magnesium-nickel alloy obtained in step (2) and put it into a ball mill jar, and put the configured high Put the molecular solution in...

Embodiment 3

[0056] Example 3 Mg 95 Ni 5 Preparation of -20%PMMA nano-magnesium-based hydrogen storage material

[0057] (1) Put 9.5g of magnesium powder and 0.5g of nickel powder into a beaker for mixing pretreatment, add 40mL of acetone as a dispersant, use ultrasonic mixing for 1h, ultrasonic power is 1KW, and then dry at 80°C for 8h , to obtain magnesium-nickel mixed powder;

[0058] (2) The magnesium-nickel mixed powder is synthesized by hydrogenation combustion method. During the synthesis process, the magnesium-nickel mixed powder is heated to 580°C for 2h in a 2MPa hydrogen atmosphere, then cooled to 340°C for 4h, and finally cooled to room temperature to obtain a powder shaped magnesium-nickel alloy.

[0059] (3) Get 0.4g PMMA and put it into a beaker, add 20mL tetrahydrofuran, stir for 1h, be mixed with a polymer solution, get 1.6g of the powdered magnesium-nickel alloy obtained in step (2) and put it into a ball mill jar, and put the configured high Put the molecular solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com