Preparation method for double-temperature-sensitive type mesoporous imprinted polymer

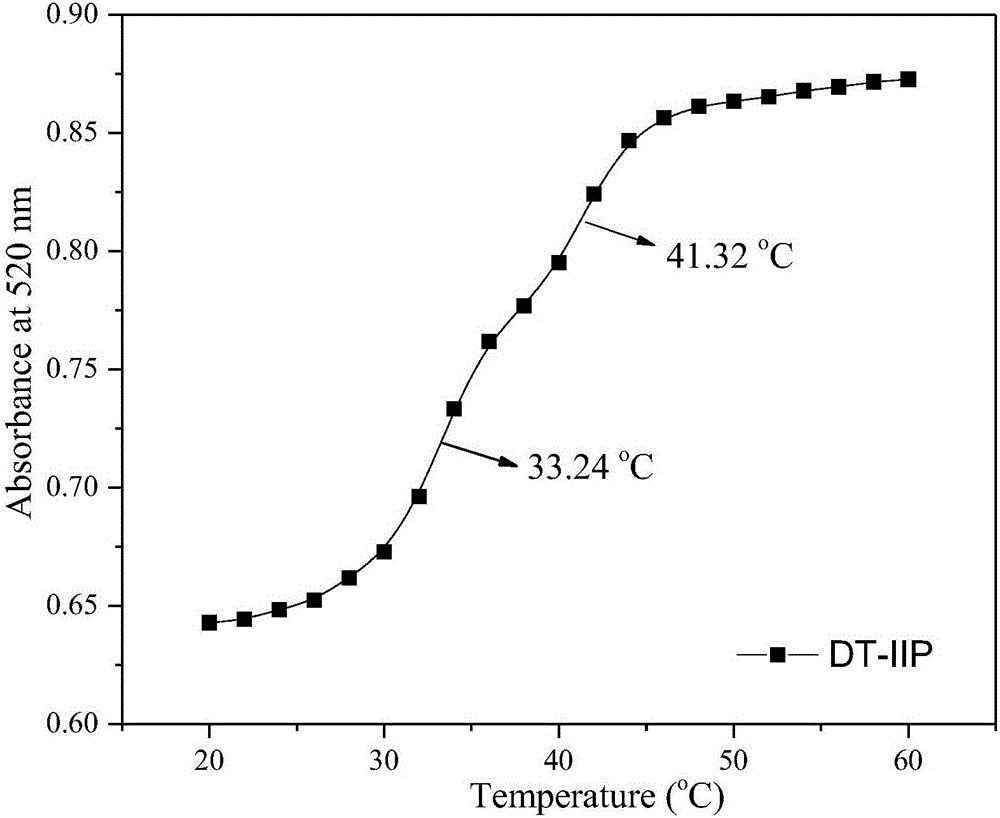

An imprinted polymer, temperature-sensitive technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems affecting the adsorption performance of imprinted polymers, lack of imprinted sites, etc. The effect of adsorption capacity, excellent temperature-sensitive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

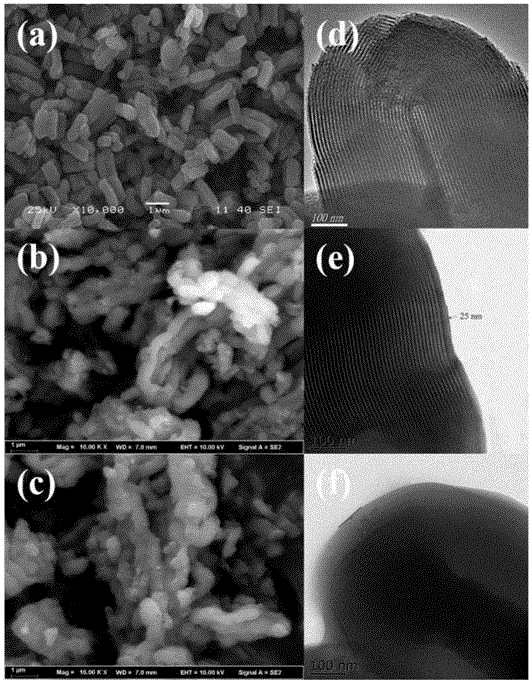

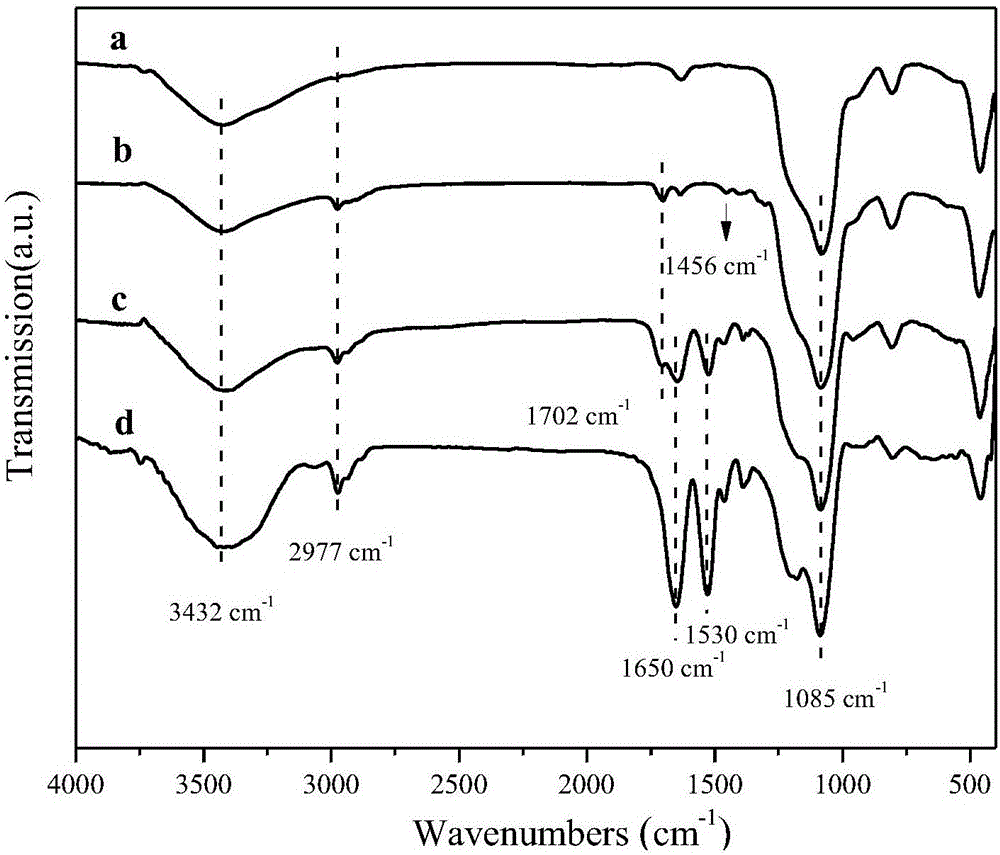

[0033] (1) Preparation of SBA-15 and its vinylation modification

[0034] Take 200mg of SBA-15 and place it in a round bottom flask, add 100mL of it to a concentration of 3mol L -1 hydrochloric acid, refluxed for 10 hours, then filtered, washed repeatedly with deionized water twice until neutral, vacuum dried at 80°C for 6 hours, and then taken out. Add activated SBA-15 and γ-(methacryloyloxy)propyltrimethoxysilane to 10-40mL toluene solution sequentially, in which 10mL γ-(methacryloyloxy) is added per gram of SBA-15 Propyltrimethoxysilane was refluxed in an oil bath for 24h under the protection of nitrogen. After the reaction, the product was successively washed three times with toluene and ethanol to remove unreacted coupling agent and toluene, and vacuum-dried to obtain a vinyl-functionalized mesoporous material (SBA-15-MPS).

[0035] (2) Preparation of monolayer thermosensitive imprinted polymer (T-IIP)

[0036] Before the start of the polymerization reaction, 15.4 mg o...

Embodiment 2

[0047] (1) The preparation of SBA-15 and its vinylation modification were carried out according to Example 1 to obtain a vinyl-functionalized mesoporous material (SBA-15-MPS).

[0048] (2) Preparation of monolayer thermosensitive imprinted polymer (T-IIP)

[0049] Before the start of the polymerization reaction, 30.8 mg of Cd(NO 3 ) 2 4H 2O and 34 μL MAA were added to 5 mL of ethanol aqueous solution (ethanol: water = 1:9, v / v, the same below), oscillated to disperse evenly, and stood in a dark place for 12 hours. Then, add 50mg of SBA-15-MPS into 20mL ethanol aqueous solution in a quartz stoppered Erlenmeyer flask, after ultrasonic dispersion, add 128mg NIPMAM, 154mg MBA, 30mg BDMAT and 20μL HMPF. After shaking and dispersing evenly, stir with magnetic force, and then seal with nitrogen gas for 20 minutes. Then, in a photochemical reaction apparatus (mercury lamp, 250W), control the internal temperature of the apparatus to room temperature (25° C.), and react with light ...

Embodiment 3

[0058] (1) The preparation of SBA-15 and its vinylation modification were carried out according to Example 1 to obtain a vinyl-functionalized mesoporous material (SBA-15-MPS).

[0059] (2) Preparation of monolayer thermosensitive imprinted polymer (T-IIP)

[0060] Before the start of the polymerization reaction, 15.4 mg of Cd(NO 3 ) 2 4H 2 O and 17 μL MAA were added to 5 mL of ethanol aqueous solution (ethanol: water = 1:9, v / v, the same below), oscillated to disperse evenly, and stood in a dark place for 12 hours. Then, add 100mg of SBA-15-MPS into 20mL ethanol aqueous solution in a quartz stoppered Erlenmeyer flask, after ultrasonic dispersion, add 56mg NIPMAM, 77mg MBA, 20mg BDMAT and 10μL HMPF. After shaking and dispersing evenly, stir with magnetic force, and then seal with nitrogen gas for 20 minutes. Then, in a photochemical reaction apparatus (mercury lamp, 250W), control the internal temperature of the apparatus to room temperature (25° C.), and react with light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com